- 28

- Sep

Gancang robah cuk pikeun quenching induktor

Gancang robah cuk pikeun quenching induktor

Sambungan antara inductor and the quenching transformer requires strong electrical connection, low resistance, and reliability. The early design of the inductor and the transformer contact plate are connected with bolts and nut washers: the intermediate frequency sensor has two rows of M12 bolts, a total of 10 bolts; the high frequency sensor also has M8 or M10 bolts, a total of 4 bolts. It is time-consuming and laborious to load and unload the sensor once, and the cooling water inlet and outlet pipes need to be connected to the sensor, which increases the auxiliary time.

Gancang-robah cuk pikeun sensor

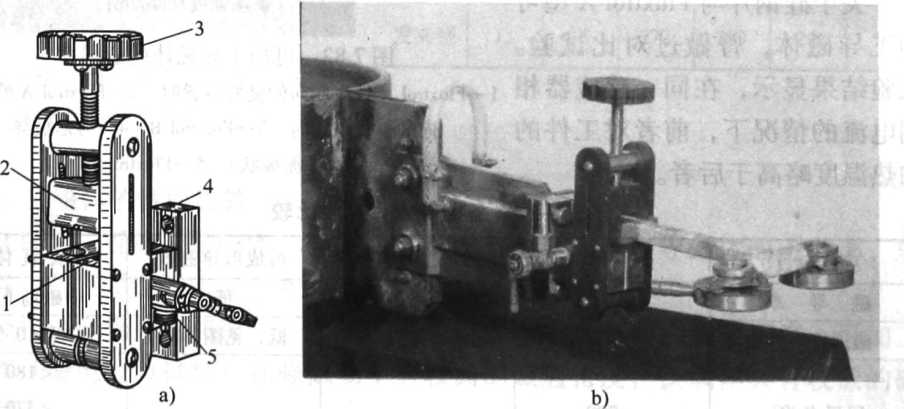

gambar nembongkeun cuk gancang-robah pikeun sensor, nu diwangun ku awak plat kontak, cecekelan mencét, blok mencét, ring sealing sarta klep inlet cai. Di tengah hareup aya port sisipan sénsor, sareng dua cingcin sealing nyaéta inlet cai sareng outlet sénsor. Nalika sensor jeung struktur baku tina blok sambungan asup kana port sisipan, pulas cecekelan 3, blok pencét bakelite pencét blok sambungan kana beungeut handap port sisipan, sarta sambungan cai jeung listrik réngsé dina hiji waktu. Nalika ngagentos sénsor, klep inlet cai 5 tiasa ditutup. Kalayan struktur ieu, peryogi sakitar 10 detik kanggo ngagentos sénsor, anu ningkatkeun efisiensi kerja sareng ngahemat tenaga kerja. cuk ieu geus loba dipaké dina produksi jeung leuwih cocog pikeun kakuatan frékuénsi luhur handap 60kW.

Gambar Sénsor robah gancang cuk na sensor

a) Gancang-robah cuk b) Gancang-robah cuk kalawan sensor

1 cincin penyegel 2 blok tekanan 3 gagang 4 badan plat kontak 5 klep asup cai