- 28

- Sep

淬火感應器快換夾頭

淬火感應器快換夾頭

之間的聯繫 inductor and the quenching transformer requires strong electrical connection, low resistance, and reliability. The early design of the inductor and the transformer contact plate are connected with bolts and nut washers: the intermediate frequency sensor has two rows of M12 bolts, a total of 10 bolts; the high frequency sensor also has M8 or M10 bolts, a total of 4 bolts. It is time-consuming and laborious to load and unload the sensor once, and the cooling water inlet and outlet pipes need to be connected to the sensor, which increases the auxiliary time.

傳感器快換夾頭

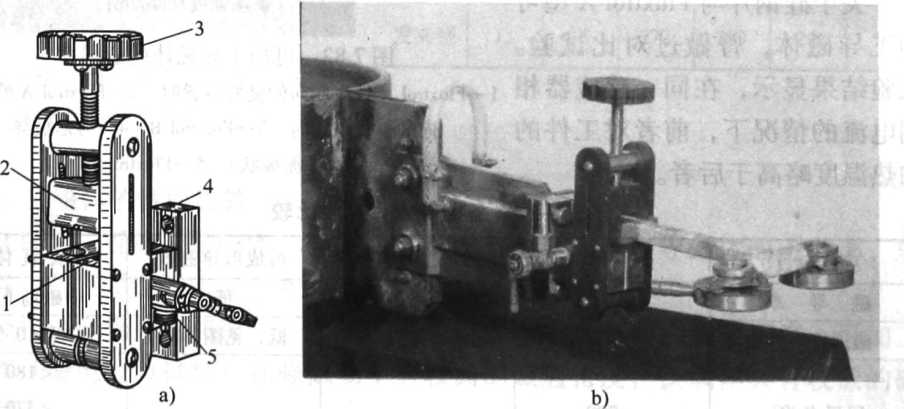

圖為傳感器用快換卡盤,由接觸板體、壓柄、壓塊、密封圈和進水閥組成。 前面中間是傳感器的插入口,兩個密封圈是傳感器的進水口和出水口。 當連接塊標準結構的傳感器進入插入口時,扭動手柄3,膠木壓塊將連接塊壓到插入口底面,一次完成水電連接。 更換傳感器時,可關閉進水閥5。 採用這種結構,更換一個傳感器大約需要10秒左右,大大提高了工作效率,節省了人工。 這種卡盤在生產中得到了廣泛的應用,更適用於60kW以下的高頻功率。

圖 Sensor 快換夾頭和傳感器

a) 快換夾頭 b) 帶傳感器的快換夾頭

1 密封圈 2-壓力塊 3-手柄 4 接觸板體 5-進水閥