- 11

- May

The difference between induction furnace and resistance furnace

Farqiga u dhexeeya foornada induction and resistance furnace

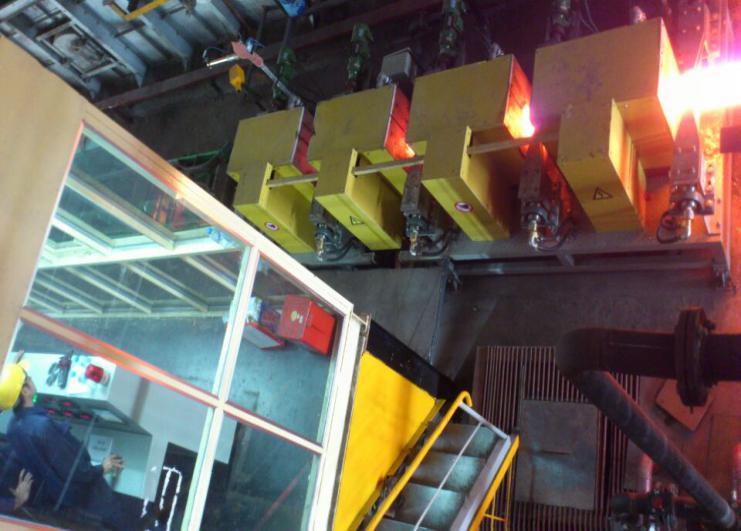

1. The heating principle of induction furnace and resistance furnace is different. Induction furnace heating adopts electromagnetic induction principle heating, and the metal workpiece itself heats up to achieve the purpose of heating; resistance furnace uses resistance wire or electric heating rod to heat the furnace, and the furnace achieves a certain temperature of heat radiation and heat. The heat is conducted to the heated metal workpiece to achieve the purpose of heating the workpiece. Simply put, the heating principle is that the induction furnace is self-heating and the resistance furnace is indirect heating.

2. The working environment of induction furnace and resistance furnace is different. Induction furnace can be combined with feeding equipment, temperature detection equipment and conveying equipment to form an automatic heating production line, which can achieve an unattended state, keep away from high temperature, and keep the site clean and tidy; resistance furnace is to make the furnace chamber It is difficult to form a heating production line by heating up and configuring the furnace door, and it is difficult to achieve automation of discharging and reclaiming materials, especially when the high-temperature workpiece is taken out of the furnace and baked at high temperature, the working environment of the operator is not good.

3. The heating speed of the induction furnace and the resistance furnace is very different. The induction furnace does not need to be prepared before opening the furnace. It can be used immediately after opening. The heating speed is fast and the heating efficiency is high. Gradually heating up, the heating time is as short as 1-2 hours, and as long as 7-8 hours. The heating speed and heating efficiency are far lower than that of induction furnaces.

4. The utilization rate of materials of induction furnace and resistance furnace is different. Due to the very fast heating speed of induction furnace, the contact time between high temperature workpiece and air is very short, so that there is little oxide scale on the surface of the workpiece, that is, very little burning loss; resistance furnace heating The metal workpiece is completely different. The metal workpiece is gradually heated by heat conduction and heat radiation in the furnace, so that the workpiece and the air in the furnace will form oxide skin to increase the amount of burning loss. The burning loss of induction furnace is generally 0.25%, and the burning loss of resistance furnace is 0.5%. %, it can be seen that the difference in the utilization rate of the material is 0.25%, which is not a small waste for heating large batches of workpieces.

5. Induction furnaces and resistance furnaces have different scopes of application. In principle, induction furnaces are used for heating metal workpieces, and are suitable for heating large quantities of single metal workpieces. It is difficult to heat non-metallic or even non-magnetic materials; resistance furnaces are metal workpieces. There is no problem in heating non-metallic materials, and even the heating of glass ceramics and other substances is handy. Therefore, the application range of resistance furnaces is wider.