- 11

- May

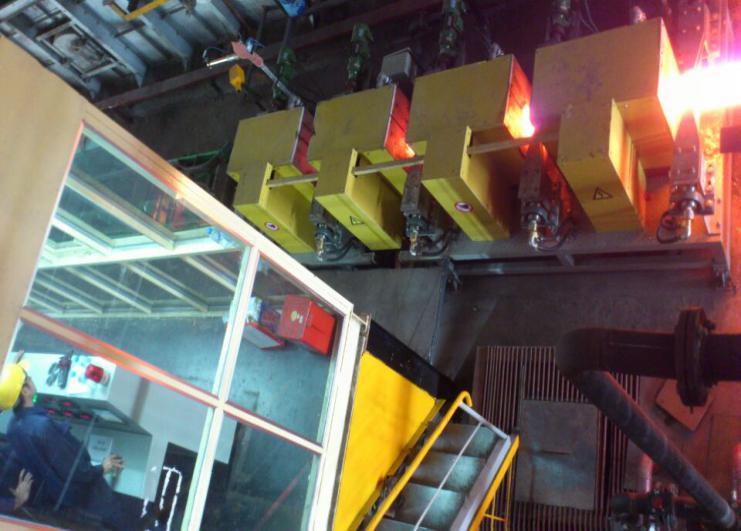

Umehluko phakathi kwesithando somlilo sokungeniswa nesithando somlilo sokumelana

Umehluko phakathi ukufakwa kwesithando somlilo kanye nesithando somlilo sokumelana

1. Isimiso sokushisa sesithando somlilo sokungeniswa nesithando somlilo sokumelana sihlukile. Ukushisisa kwesithando sokufakelwa kwe-induction kusebenzisa isimiso sokufudumeza kwe-electromagnetic induction, futhi ucezu lwensimbi ngokwalo luyashisa ukuze kufezwe inhloso yokushisisa; isithando somlilo sisebenzisa intambo yokumelana noma induku yokushisa kagesi ukushisa isithando somlilo, futhi isithando somlilo sifinyelela izinga lokushisa elithile lokushisa kwemisebe nokushisa. Ukushisa kuqhutshelwa ku-workpiece yensimbi evuthayo ukuze kuzuzwe inhloso yokushisa i-workpiece. Kalula nje, isimiso sokushisa siwukuthi isithando somlilo se-induction siyazifudumeza futhi isithando somlilo sokumelana sishisa ngokungaqondile.

2. Indawo yokusebenza yesithando somlilo sokungeniswa nesithando somlilo sokumelana sihlukile. Isithando somlilo se-induction singahlanganiswa nemishini yokuphakela, imishini yokubona izinga lokushisa kanye nemishini yokudlulisa ukwenza umugqa wokukhiqiza ozenzakalelayo wokushisa, ongafinyelela isimo esinganakiwe, ugweme ukushisa okuphezulu, futhi ugcine indawo ihlanzekile futhi icocekile; isithando somlilo sokumelana ukwenza igumbi lesithando somlilo Kunzima ukwenza umugqa wokukhiqiza wokushisa ngokushisa futhi ulungise umnyango wesithando somlilo, futhi kunzima ukufeza ukuzenzekelayo kokukhipha nokubuyisela izinto, ikakhulukazi lapho umshini wokushisa ophezulu ukhishwa ngaphandle. isithando somlilo futhi kubhakwa ekushiseni okuphezulu, indawo yokusebenza ye-opharetha ayilungile.

3. Isivinini sokushisa kwesithando somlilo sokungeniswa nesithando somlilo sokumelana sihluke kakhulu. Isithando somlilo sokungeniswa asidingi ukulungiswa ngaphambi kokuvula isithando somlilo. Ingasetshenziswa ngokushesha ngemva kokuvula. Isivinini sokushisisa siyashesha futhi ukusebenza kahle kokushisisa kuphezulu. Ukushisa kancane kancane, isikhathi sokushisa sifushane njengamahora angu-1-2, futhi ubude bamahora angu-7-8. Isivinini sokushisisa nokusebenza kahle kokushisisa kuphansi kakhulu kunaleso leziko lokungeniswa.

4. Izinga lokusetshenziswa kwezinto zesithando somlilo sokungeniswa nesithando somlilo sokumelana lihlukile. Ngenxa yesivinini sokushisa esisheshayo sesithando sokufakelwa, isikhathi sokuxhumana phakathi komshini wokushisa ophezulu kanye nomoya sifushane kakhulu, ukuze kube nesikali esincane se-oxide ebusweni bomsebenzi, okungukuthi, ukulahlekelwa okuncane kakhulu okuvuthayo; ukumelana nesithando somlilo I-workpiece yensimbi ihluke ngokuphelele. I-workpiece yensimbi iyashiswa kancane kancane yi-heat conduction kanye nemisebe yokushisa esithandweni somlilo, ukuze i-workpiece kanye nomoya esithandweni somlilo kuzokwakha isikhumba se-oxide ukwandisa inani lokulahlekelwa okuvuthayo. Ukulahlekelwa okuvuthayo kwesithando somlilo ngokuvamile ku-0.25%, futhi ukulahlekelwa okuvuthayo kwesithando somlilo kungu-0.5%. %, kungabonakala ukuthi umehluko wezinga lokusebenzisa impahla ngu-0.25%, okungeyona imfucuza encane yokushisisa amaqoqo amakhulu ezinto zokusebenza.

5. Iziqhumiso zokungeniswa kanye neziqhumane zokumelana zinezindawo ezihlukene zokusebenzisa. Ngokomthetho, izithando zokufakelwa zisetshenziselwa ukushisa izinsimbi zokusebenza zensimbi, futhi zifanele ukushisa inani elikhulu lezinto zokusebenza zensimbi eyodwa. Kunzima ukushisa izinto ezingezona ezensimbi noma ezingezona kazibuthe; Izithando zomlilo ziyizicucu zensimbi. Ayikho inkinga ekushiseni izinto ezingezona ezensimbi, futhi ngisho nokushisa kwengilazi ye-ceramics nezinye izinto kuyasiza. Ngakho-ke, uhla lwezicelo lwezithando zokushisa lubanzi.