- 17

- Nov

Selection and application of intermediate frequency induction heating equipment

Selection and application of intermediate frequency induction heating equipment

Medium frequency induction heating equipment uses induction current to heat the surface of the workpiece locally. This heat treatment process is often used for surface quenching, it can also be used for partial annealing or tempering, and sometimes it is also used for overall quenching and tempering. With the development of industry, induction heating heat treatment technology has been continuously improved, and the scope of application has also been continuously expanded.

The selection of intermediate frequency power equipment is related to the depth of the heating layer required by the workpiece. For workpieces with deep heating layer, use power equipment with lower current frequency; for workpieces with shallow heating layer, use power equipment with higher current frequency. Another condition for selecting power equipment is equipment power. As the heating surface area increases, the required power supply increases accordingly. When the heating surface area is too large or the power supply is insufficient, continuous heating can be used to move the workpiece and the inductor relative to each other, heating at the front and cooling at the back. Heat the entire heating surface at once. In this way, the residual heat of the core of the workpiece can be used to temper the hardened surface layer, thereby simplifying the process and saving electric energy.

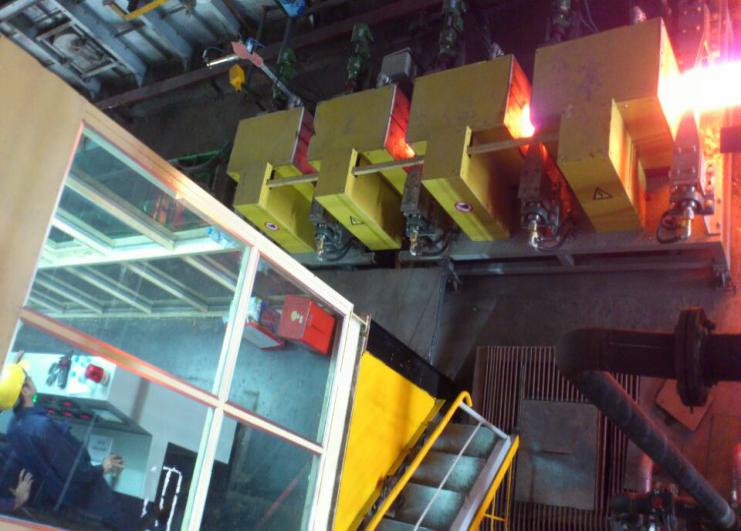

During the working process of the steel rod intermediate frequency induction heating equipment, in order to ensure the quality of heat treatment and improve the thermal efficiency, an inductor with an appropriate structure must be designed and manufactured according to the shape and requirements of the workpiece. Commonly used inductors include external surface heating inductors, inner hole heating inductors, and planar heating inductors.