- 28

- Jun

Indlela yokukhetha yentsimbi yesithando somlilo somzimba we-induction melting

Indlela yokukhetha iqokobhe lesithando somlilo somzimba we ukuchithwa kwesithando somlilo

1. Iziko

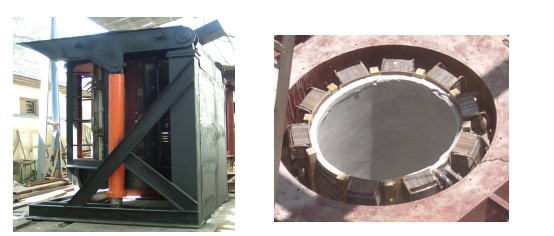

Umzimba wesithando somlilo uqulunqwe nge-coil induction, idyokhwe yamagnetic, isakhelo sesithando somlilo, isilinda esithambekileyo njalo njalo.

Coil coil

I-coil induction yenziwe nge-99.9% ityhubhu yethusi yoxande. I-coil ye-induction ithatha inkqubo yokugubungela i-mica tape kunye nokudipha i-varnish yokukhusela. Umphezulu utshizwe ngoluhlu lwe-grey insulating varnish, kwaye i-voltage yokumelana ne-insulating layer ingaphezu kwe-5000V.

I-coil ye-induction igxininiswe ngoluhlu lweebholiti kunye ne-insulating zihlala zidibeneyo kwi-circumference yayo yangaphandle. Emva kokuba ikhoyili ilungisiwe, impazamo ye-turn pitch yayo ayikho ngaphezulu

ngaphezu kwe 2mm.

Zomibini iindawo eziphezulu kunye nezisezantsi ze-coil induction zixhotyiswe ngentsimbi yensimbi engenasici yokupholisa amakhonkco okupholisa amanzi, injongo yokufudumeza ngokufanayo i-furnace lining material kwi-axial direction kunye nokwandisa ubomi benkonzo yesithando somlilo.

Kwindawo yokuphuma kwamanzi kwi-coil induction, iiprobes ezininzi zokushisa kwamanzi zifakwe ngokwesekethe yamanzi. Xa ubushushu bamanzi bendlela ethile buvaliwe, i-alam inokukhutshwa ngokukhawuleza kwaye unikezelo lwamandla ombane oluphakathi lunokuvalwa ngokuzenzekelayo.

1.2, idyokhwe

Idyokhwe yenziwe nge-silicone yentsimbi epholileyo eqengqelekayo kunye nokungena okuphezulu. Ubukhulu bephepha lensimbi ye-silicon yi-0.3 mm. Ijoka ithatha isakhiwo seprofayili, kwaye i-arc ye-arc yangaphakathi iyafana ne-arc yesangqa sangaphandle se-coil induction, ukwenzela ukuba ijoka ihanjiswe ngokulinganayo ngaphandle kwe-coil induction, ethintela i-radiated magnetic. intsimi yekhoyili ukuya kwinqanaba eliphezulu kwaye inciphisa isiphaluka sangaphandle samagnetic Magnetoresistance.

Ijoka yeendawo ezisengozini igxininiswe ngamacwecwe ensimbi engenasici kunye neentambo zensimbi ezingenasici kumacala omabini kwaye zilungiswe nge-welding. Umbhobho wamanzi okupholisa udityaniswa kwipleyiti yentsimbi engatyiwa macala omabini ukupholisa idyokhwe. Umbhobho wamanzi okupholisa unokumelana ne-0.45Mpa yoxinzelelo lwamanzi ngaphandle kokuvuza kwimizuzu eyi-15.

Emva kokuba ijoka ihlanganiswe, i-curvature ayikho ngaphezu kwe-4mm, kwaye ukuphambuka phakathi kwe-centerline ye-theoretical kunye ne-centerline yangempela ayikho ngaphezu kwe-3mm.

Iipleyiti zeTeflon kunye neepleyiti zeerubha ze-asbestos zifakwe ngaphakathi ukuya ngaphandle phakathi kwejoka kunye nekhoyili. Iphepha le-Teflon linamandla aphezulu okugquma kunye nokumelana nobushushu obuphezulu, kunye neshiti lerabha ye-asbestos inokumelana nobushushu obuphezulu. Oku kuqinisekisa ukugquma kunye nokumelana nobushushu phakathi kwedyokhwe kunye nekhoyili.

Idyokhwe nganye igxininiswe ngentonga yesikrufu emiswe kwiqokobhe lesithando somlilo ukuze yenze iyunifomu yokutyhala amandla kwisangqa sekhoyili, ukuze zombini idyokhwe kunye nekhoyili zilungiswe, kwaye ikhoyili ayiyi kuveliswa ngexesha lokunyibilika nokuphuma ngaphandle. iziko. shukuma.

1.3. Isitovu

Isakhelo sesithando somlilo sahlulwe sibe ngamacandelo amabini: eshukumayo kwaye esisigxina.

1.3.1, isitovu esinokususwa

Isakhelo somlilo esishukumayo sisetyenziselwa ukufakela i-coil induction kunye nejoka lamagnetic. Idityaniswe yintsimbi yecandelo kunye nentsimbi yensimbi, kwaye ithatha isakhiwo sesakhelo sokugcinwa lula. Iqonga lokusebenza phezulu kwi-grate ehambayo ithatha iiplate zetsimbi ezityebileyo zokuphucula amandla kunye nomthwalo wokuthwala i-grate.

1.3.2, isitovu esingatshintshiyo

Isakhelo somlilo esisisigxina sifakwe kwisiseko sokuthwala isakhelo somlilo esishukumayo. Ingxenye ephezulu ye-grate esisigxina idibaniswe kwi-grate ehambayo ngokusebenzisa i-shaft tilting, kwaye i-grate ehambayo inokunyuswa phambili ngama-95 degrees phantsi kwe-push ye-cylinder yeoli.

Ukhuseleko olukhulu lugcinwe kuyilo lwenxalenye yegrate. Qinisekisa ukuba isakhelo sesithando somlilo sinokuqina okwaneleyo kwaye sihamba kakuhle xa sithwele umthwalo omkhulu.

1.4 Isigqubuthelo somlilo

Isigqubuthelo somlilo sifakwe kwisakhelo somlilo esishukumayo. Isigqubuthelo somlilo singasetyenzwa ngesandla kunye ne-hydraulically.

1.4.1, isigqubuthelo somlilo wezandla

Isigqubuthelo sesithando somlilo sifakwe kwi-shaft ejikelezayo kwicala eliphezulu lomzimba wesithando somlilo, kunye nesigqubuthelo somlilo singavulwa kwaye sivalwe ngokuhambisa isibambo phezulu nasezantsi. Xa uhlawula okanye ungadingi ukusebenzisa isigqubuthelo somlilo, isigqubuthelo somlilo sinokujikelezwa kwindawo yecala lendawo ephezulu yesithando somlilo.

1.4.2. Isigqubuthelo somlilo esiqhutywa ngamanzi:

Isigqubuthelo somlilo esiqhutywa nge-hydraulically sifakwe kwi-shaft ejikelezayo kwicala eliphezulu lomzimba wesithando somlilo, kwaye ukuvulwa kunye nokujikeleza kwesigqubuthelo sesithando somlilo kufezekiswa ngezenzo zeesilinda zeoli eziphezulu kunye nezantsi kunye ne-cylinder yeoli ejikelezayo. Sebenza ngokutshintshwa komsebenzi kwi-console. Xa uhlawula okanye ungadingi ukusebenzisa isigqubuthelo somlilo, isigqubuthelo somlilo sinokujikelezwa kwindawo yecala lendawo ephezulu yesithando somlilo.