- 28

- Jun

Indlela yokukhetha yesithando somlilo segobolondo lensimbi yesithando somlilo esincibilikayo

Indlela yokukhetha yensimbi yegobolondo lesithando somlilo umzimba we ukuchithwa kwesithando somlilo

1. Isithando Somlilo

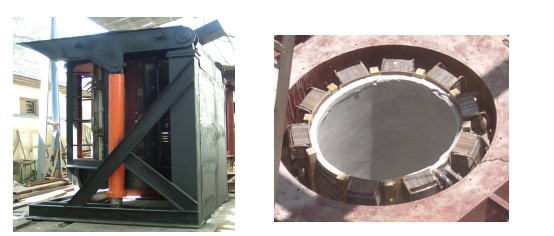

Umzimba wesithando somlilo wakhiwe ngekhoyili yokungeniswa, ijoka kazibuthe, ifreyimu yesithando somlilo, isilinda esitshekisayo nokunye.

Ikhoyili ye-Induction

Ikhoyili yokungeniswa yenziwe ngeshubhu yethusi elingunxande elingu-99.9%. Ikhoyili yokungeniswa yamukela inqubo yokugoqa i-mica tape kanye nokucwiliswa kwevarnish evikelayo. Ingaphezulu lifafazwa ngongqimba lwe-varnish evikelayo empunga, futhi amandla okumelana nesendlalelo se-insulating mkhulu kuno-5000V.

Ikhoyili ye-induction ilungiswa ngochungechunge lwamabhawodi kanye nezindawo zokuvikela ezokuvikela ezishiselwe esiyingini sayo sangaphandle. Ngemuva kokuthi ikhoyili isilungisiwe, iphutha le-turn pitch yalo alikho ngaphezulu

awu 2mm.

Kokubili izingxenye ezingaphezulu neziphansi zekhoyili yokungeniswa zifakwe izindandatho zensimbi ezingenasici zokupholisa amanzi, inhloso yazo okuwukushisa ngokulinganayo izinto ezifakwa esithandweni somlilo ekuqondeni kwe-axial nokwandisa impilo yesevisi yolayini lwesithando somlilo.

Emthonjeni wamanzi wekhoyili ye-induction, ama-probe amaningana okushisa kwamanzi afakwe ngokuvumelana nomjikelezo wamanzi. Uma izinga lokushisa lamanzi lomgwaqo othile livaliwe, i-alamu ingakhishwa ngokushesha futhi ukunikezwa kwamandla okuvama okumaphakathi kungavalwa ngokuzenzakalelayo.

1.2, ijoka

Ijoka lenziwe ngeshidi lensimbi ye-silicon egoqwe ngokubanda elikwazi ukungena kalula. Ubukhulu beshidi lensimbi ye-silicon buyi-0.3 mm. Ijoka lithatha isakhiwo sephrofayili, futhi i-arc ye-arc yangaphakathi ifana ne-arc yendilinga yangaphandle yekhoyili yokungeniswa, ukuze ijoka likwazi ukusatshalaliswa ngokulinganayo ngaphandle kwekhoyili yokungeniswa, evimbela i-radiated magnetic. inkambu yekhoyili ngokwezinga eliphezulu futhi inciphisa isifunda samagnetic sangaphandle I-Magnetoresistance.

Ijoka lezingxenye ezisengozini liboshwe amapuleti ensimbi engagqwali kanye nezinsimbi zensimbi ezingenasici nhlangothi zombili futhi zilungiswa ngokushisela. Ipayipi lamanzi okupholisa lishiselwa epuletini lensimbi engagqwali nhlangothi zombili ukuze lipholise ijoka. Ipayipi lamanzi okupholisa lingakwazi ukumelana nomfutho wamanzi ongu-0.45Mpa ngaphandle kokuvuza kungakapheli imizuzu eyi-15.

Ngemuva kokuba ijoka liqoqwe, i-curvature ayikho ngaphezu kwe-4mm, futhi ukuphambuka phakathi kwe-centerline ye-theoretical kanye ne-centerline yangempela ayikho ngaphezu kwe-3mm.

Amapuleti e-Teflon namapuleti enjoloba e-asbestos akleliswe kusukela ngaphakathi kuya ngaphandle phakathi kwejoka nekhoyili. Ishidi le-Teflon linamandla okushisa aphezulu kanye nokumelana nokushisa okuphezulu, futhi ishidi lerabha le-asbestos linokumelana nokushisa okuphezulu. Lokhu kuqinisekisa ukumelana nokushisa phakathi kwejoka nekhoyili.

Ijoka ngalinye lilungiswa ngenduku yesikulufu esibekwe egobolondweni lesithando somlilo ukuze kwakhiwe amandla afanayo aphushayo endaweni eyindilinga yekhoyili, ukuze kokubili ijoka nekhoyili kulungiswe, futhi ikhoyili ngeke ivezwe ngesikhathi sokuncibilika nokuphuma isithando somlilo. hambisa.

1.3. Isitofu

Uhlaka lwesithando somlilo luhlukaniswe izingxenye ezimbili: ezihambayo nezilungisiwe.

1.3.1, isitofu esinyakazayo

Uhlaka lwesithando somlilo olususwayo lusetshenziselwa ukufaka ikhoyili yokungeniswa kanye nejoka kazibuthe. Ihlanganiswe ngensimbi yesigaba kanye ne-steel plate, futhi yamukela isakhiwo sohlaka ukuze sigcinwe kalula. Inkundla yokusebenza engaphezulu kwe-grate egudlukayo ithatha amapuleti ensimbi ajiyile ukuze kuthuthukiswe amandla namandla okuthwala umthwalo we-grate.

1.3.2, ihabhu engashintshi

Uhlaka lwesithando somlilo esingaguquki lufakwe esisekelweni ukuze luthwale ifreyimu yesithando somlilo esinyakazayo. Ingxenye engenhla ye-grate engaguquki ixhunywe ku-grate ehambayo ngokusebenzisa i-shaft enyakazayo, futhi i-grate ehambayo ingase iqhubekele phambili ngama-degrees angu-95 ngaphansi kokusunduza kwesilinda samafutha enyakazayo.

Isici esikhulu sokuphepha sigcinwe ekwakhiweni kwengxenye ye-grate. Qinisekisa ukuthi uhlaka lwesithando somlilo lunokuqina okwanele futhi luhamba kahle uma uthwele umthwalo omkhulu.

1.4 Ikhava yesithando somlilo

Ikhava yesithando somlilo ifakwe ohlakeni lwesithando somlilo esinyakazayo. Isembozo sesithando somlilo singasetshenzwa ngesandla nange-hydraulically.

1.4.1, ikhava yesithando somlilo esenziwa ngesandla

Isembozo sesithando somlilo sifakwe ku-shaft ejikelezayo ohlangothini olungaphezulu lomzimba wesithando somlilo, futhi isembozo somlilo singavulwa futhi sivalwe ngokuhambisa isibambo phezulu naphansi. Uma ushaja noma ungadingi ukusebenzisa ikhava yesithando somlilo, isembozo sesithando somlilo singazungezwa endaweni eseceleni yengxenye engenhla yesithando somlilo.

1.4.2. Ikhava yesithando somlilo esiqhutshwa ngamanzi:

Isembozo somlilo esiqhutshwa nge-hydraulically sifakwe ku-shaft ejikelezayo ohlangothini olungaphezulu lomzimba wesithando somlilo, futhi ukuvulwa nokujikeleza kwesembozo sesithando somlilo kubonakala ngezenzo zamasilinda amafutha aphezulu naphansi kanye nesilinda samafutha ajikelezayo. Sebenza ngeswishi yokusebenza ku-console. Uma ushaja noma ungadingi ukusebenzisa ikhava yesithando somlilo, isembozo sesithando somlilo singazungezwa endaweni eseceleni yengxenye engenhla yesithando somlilo.