- 05

- Sep

Ukwakheka nokuhlukaniswa kwe-vacuum induction furnace

Ukwakheka nokuhlukaniswa kwe-vacuum induction furnace

Isakhiwo sesithando somlilo sokungeniswa kwevacuum

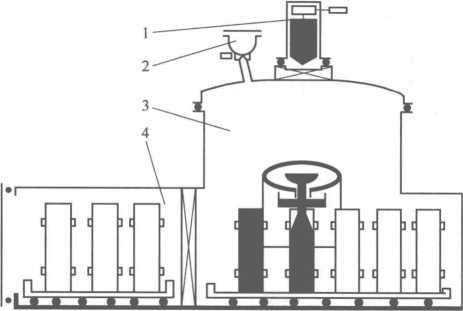

Isithando somlilo sokungenisa i-vacuum ngokuyinhloko sakhiwe izingxenye ezilandelayo: umzimba wesithando sokungenisa (okuhlanganisa idivayisi yokuncibilika), isistimu ye-vacuum, idivayisi yokuhlinzeka ngogesi, uhlelo lokupholisa amanzi, uhlelo lwe-hydraulic, uhlelo lwe-pneumatic, uhlelo lokulawula ugesi, kanye nokunikezwa kwamandla okuvama okuphakathi. Isakhiwo sesithando somlilo sokungeniswa kwevacuum siboniswa kuMfanekiso 5-1.

Umfanekiso 5-1 Isithando somlilo esijwayelekile sokufakwa kwevacuum

1-Igumbi lokudla elikhulu; I-2-Igumbi lokudla ingxubevange; 3-Igumbi lokuncibilikisa; 4 – Igumbi lokugezela

Kunamakhoyili angeniswayo, izintambo zikagesi ezipholiswe ngamanzi, amasilinda esithandweni se-hydraulic tilting, kanye nemoto yokubunjwa ngaphakathi nangaphandle imishini yokudlulisa efakwe egunjini elincibilikayo. Kukhona umnyango omkhulu phakathi kwegumbi le-ingot kanye negumbi lokuncibilikisa, elivame ukubizwa ngokuthi umnyango wangaphakathi, ohlukanisa igumbi lokuncibilikisa negumbi le-ingot. I-mold ingot chamber ifakwe umnyango wangaphandle, futhi imoto yesikhunta isetshenziswa ngaphakathi nangaphandle ngokuvula nokuvala iminyango yangaphakathi nengaphandle ukuze kugcinwe indawo engenalutho yegumbi elincibilikayo futhi ibone ukwenza insimbi okungaqhubekiyo. Igumbi lokuphakela eliyinhloko kanye negumbi lokuphakela i-alloy liphinde lihlukaniswe negumbi lokuncibilikisa ngama-valve, ukuze i-vacuum yegumbi lokuncibilikisa ingonakalisiwe lapho isondla. Izithando zokungenisa ivacuum zendabuko zinegumbi elikhulu kakhulu elincibilikayo. Isibonelo, isithando somlilo esinomthamo we-5t sinomthamo wekamelo elincibilikayo elingu-60m3. Ngisho noma inkulu kakhulu, ukugcinwa kwayo kwangaphakathi kunzima kakhulu futhi izindleko zokusebenza ziphezulu kakhulu (ikakhulukazi ukusetshenziswa kwe-oxygen). Igumbi lesikhunta linqunywa inombolo nokuhleleka kwama-spindle, futhi ngokuvamile kunzima ukushwabana. Ivolumu yegumbi le-ingot ye-vacuum induction mold inqunywa umthamo wesithando somlilo, inani lama-spindle adingwa ngumsebenzisi, ububanzi nobude, futhi kunzima ukuwehlisa.