- 08

- Oct

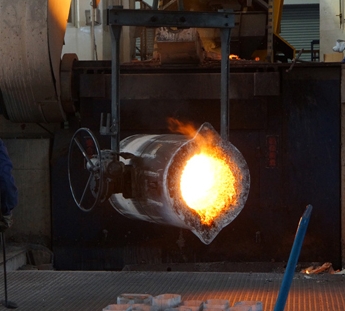

Precautions for safe operation of metal melting furnace

Precautions for safe operation of metal melting furnace

1. Preparation before opening the furnace

(1) Check the furnace lining. When the thickness of the furnace lining (excluding asbestos plate) is less than 65-80 mm after wear, the furnace must be repaired;

(2) Check for cracks. Cracks above 3 mm should be filled with furnace lining materials for repair;

(3) Ensure that the cooling water is unblocked.

2. Feeding instructions

After putting in the furnace cover, check whether the furnace block is actually placed at the bottom of the furnace;

Do not let wet charge in. As a last resort, after putting in the dry charge, put the wet material on top of it, and use the method of drying by the heat in the furnace to evaporate the water before furnaceization;

Chips should be placed on the remaining molten iron after tapping as much as possible. The amount of input at a time is less than one-tenth of the furnace amount, and it must be evenly input;

(4) Do not add tubular or hollow charge. This is due to the rapid expansion of the air, which may be in danger of explosion;

(5) Regardless of the charge, put in the next melt before the last charge is melted.

(6) If you use a charge with a lot of rust and sand, or add too much cold charge at one time, “bridging” is easy to occur, and the liquid level must be checked frequently to avoid “bridging”, the lower molten iron will overheat, causing the lower lining The corrosion, even leakage of molten iron.

3. Management of molten iron temperature in metal melting furnace

The tapping temperature should not exceed the required value. Too high molten iron temperature greatly reduces the life of the furnace lining. As the acid furnace lining reaches above 1500°C, it is carried out very quickly, and the composition of the molten iron also changes. The carbon element burns and the silicon content increases.