- 05

- Aug

Annealing process of induction heating pit furnace coil wire

Proces žarenja induction heating pit furnace žica zavojnice

Specifičan rad i učinak obrade žarenja kotura od alatnog čelika T10 korištenjem jamskih peći za indukcijsko grijanje predstavljeni su kako slijedi.

The loading capacity of the coils Load 10 rolls of T10 tool steel coils with a diameter of 8mm, about 1

Snaga grijanja koju koristi snaga indukcijskog grijanja je 95~130kW, zagrijava se na oko 740°C za 2~4h, a zatim se vrši žarenje i očuvanje topline.

Annealing treatment process Adjust the temperature to 720~740°C, keep it for 30~40min, then furnace cool to 680°C, and then air-cooled.

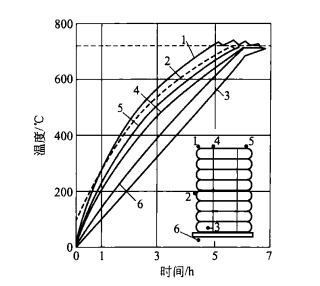

During the induction heating process, the heating curve of different points in the coil stack in the furnace is shown in Figure 8-17. When the loading amount is 3.0, the heating time is about 6 hours to make the coil reach the predetermined temperature, and the temperature difference between the inside and outside of the coil is controlled at 10-15°C. This temperature control accuracy is better than pit-type resistance furnaces and bell-type furnaces, and better than fuel-heated continuous annealing furnaces. During continuous heating and annealing, the heating time will be shortened by about 1h compared with the temperature rise of a cold furnace.

During the induction heating process, the heating curve of different points in the coil stack in the furnace is shown in Figure 8-17. When the loading amount is 3.0, the heating time is about 6 hours to make the coil reach the predetermined temperature, and the temperature difference between the inside and outside of the coil is controlled at 10-15°C. This temperature control accuracy is better than pit-type resistance furnaces and bell-type furnaces, and better than fuel-heated continuous annealing furnaces. During continuous heating and annealing, the heating time will be shortened by about 1h compared with the temperature rise of a cold furnace.

Slika 8-17 Kriva grijanja svake tačke mjerenja temperature u okruglom dimnjaku peći za indukcijsko grijanje