- 05

- Aug

Annealing process of induction heating pit furnace coil wire

Annealing process of induction heating pit furnace coil wire

The specific operation and treatment effect of annealing T10 tool steel coils using induction heating pit furnaces are introduced as follows.

The loading capacity of the coils Load 10 rolls of T10 tool steel coils with a diameter of 8mm, about 1

The heating power used by the induction heating power is 95~130kW, heated to about 740°C in 2~4h, and then annealing and heat preservation are carried out.

Annealing treatment process Adjust the temperature to 720~740°C, keep it for 30~40min, then furnace cool to 680°C, and then air-cooled.

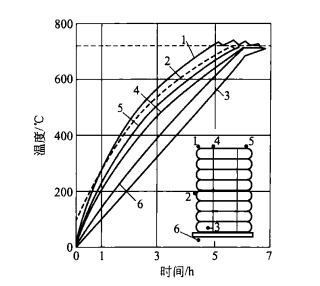

During the induction heating process, the heating curve of different points in the coil stack in the furnace is shown in Figure 8-17. When the loading amount is 3.0, the heating time is about 6 hours to make the coil reach the predetermined temperature, and the temperature difference between the inside and outside of the coil is controlled at 10-15°C. This temperature control accuracy is better than pit-type resistance furnaces and bell-type furnaces, and better than fuel-heated continuous annealing furnaces. During continuous heating and annealing, the heating time will be shortened by about 1h compared with the temperature rise of a cold furnace.

During the induction heating process, the heating curve of different points in the coil stack in the furnace is shown in Figure 8-17. When the loading amount is 3.0, the heating time is about 6 hours to make the coil reach the predetermined temperature, and the temperature difference between the inside and outside of the coil is controlled at 10-15°C. This temperature control accuracy is better than pit-type resistance furnaces and bell-type furnaces, and better than fuel-heated continuous annealing furnaces. During continuous heating and annealing, the heating time will be shortened by about 1h compared with the temperature rise of a cold furnace.

Figure 8-17 The heating curve of each temperature measurement point in the round stack of the induction heating pit furnace