- 29

- Sep

Txoj kev rau melting steel thiab seem hlau nyob rau hauv induction melting rauv

Method for melting steel and scrap steel in induction melting rauv

Ua ntej lub cub tawg induction yuav tsum tau them, cov seem nyob rau hauv lub cub tawg yuav tsum tau muab tshem tawm, thiab kev puas tsuaj ntawm lub qhov cub yuav tsum tau kuaj xyuas. Cov khoom uas raug puas ntsoog tau dhau los ua cov xim dub vim qhov txias txias thiab yuav tsum tau kho. Cov nplej loj ntawm cov khoom kho yuav tsum me ntsis me dua li cov khoom siv knotted, thiab cov binder siv yuav tsum me ntsis ntau dua. Cov qhov cub loj loj uas muaj kev puas tsuaj loj tuaj yeem nqa mus rau hauv lub cub tawg hlau pwm los sau cov pob caus.

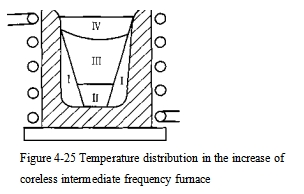

Txij li thaum qhov kub ntawm qhov cub induction poob sai sai tom qab tapping, nws yuav tsum tau them sai sai thiab yuav tsum tau ntim nrog cov thoob ntau li ntau tau. Txhawm rau kom ceev cov melting, cov khoom siv yuav tsum tau muab faib kom tsim nyog raws li qhov ntsuas kub hauv qhov cub. Kev faib tawm qhov kub thiab txias hauv qhov cub induction yog qhia hauv daim duab 4-25. Vim yog cov nyhuv ntawm daim tawv nqaij tam sim no, qhov chaw nyob ib puag ncig ntawm cov khoom siv kem (zone I) nyob ze ntawm phab ntsa ntawm lub volute yog thaj chaw kub siab.

Hauv qab thiab nruab nrab (I, TT cheeb tsam) muaj cov cua kub tsis zoo, uas yog thaj chaw kub siab dua, thiab sab sauv (IV tsam) muaj qhov sib nqus flux tsawg dua thiab cov cua sov loj, uas yog thaj chaw kub tsawg.

Txhawm rau tsim cov slag ua ntej, 1% ntawm cov khoom siv slag los ntawm qhov hnyav tuaj yeem muab ntxiv rau hauv qab ntawm lub qhov cub ua ntej them, txiv qaub thiab fluorite ntxiv rau hauv qhov cub alkaline, thiab iav cullet ntxiv rau cov kua qaub.

Thaum pib ntawm melting, vim hais tias qhov inductance thiab capacitance ntawm kab tsis tuaj yeem sib phim sai thiab zoo, qhov tam sim no tsis ruaj khov, yog li nws tsuas yog muab tau nrog lub zog qis hauv lub sijhawm luv. Thaum qhov tam sim no ruaj khov, nws yuav tsum tau hloov mus rau tag nrho cov khoom xa tawm. Thaum lub sij hawm melting txheej txheem, lub capacitor yuav tsum tau hloov tas li kom cov khoom siv hluav taws xob nrog lub zog loj. Tom qab tus nqi yog melted kiag li, cov hlau molten yog overheated rau ib qho twg, thiab tom qab ntawd lub zog input raug txo raws li qhov yuav tsum tau smelting.

Lub sij hawm melting kom raug yuav tsum tau tswj. Yog hais tias lub sij hawm melting yog luv luv, nws yuav ua rau muaj teeb meem nyob rau hauv kev xaiv ntawm voltage thiab capacitance. Yog tias nws ntev dhau lawm, nws yuav ua rau kom tsis muaj kev kub ntxhov. Cov ntaub ntawv tsis raug lossis cov xeb ntau dhau hauv cov khoom siv hauv qhov cub yuav ua rau “txhim kho” qhov tshwm sim, uas yuav tsum tau ua raws sijhawm. “Bridge” tiv thaiv cov khoom uas tsis tau yaj nyob rau sab sauv los ntawm kev poob rau hauv cov hlau molten, stagnating lub yuhua, thiab overheating hauv qab ntawm cov hlau molten tuaj yeem ua rau lub qhov cub tawg yooj yim, thiab nws tseem yuav ua rau cov hlau molten nqus tau ntau heev. ntawm gas.

Vim yog electromagnetic stirring, nruab nrab ntawm cov hlau molten bulges, thiab cov slag feem ntau ntws mus rau ntawm ntug ntawm lub crucible thiab adheres rau lub cub tawg phab ntsa. Yog li ntawd, lub slag yuav tsum tsis tu ncua ntxiv raws li lub cub tawg thaum lub sij hawm melting txheej txheem.