- 11

- Feb

Method for induction heat treatment of steel strip

Method for induction heat treatment of steel strip

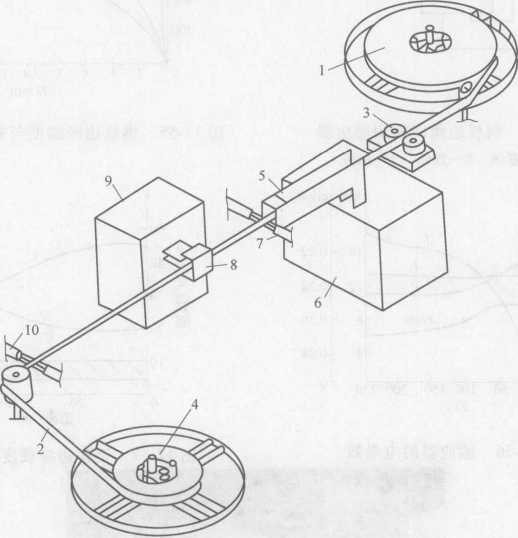

Mengikut keperluan penggunaan, tali pinggang keluli mesti mempunyai kedua-dua rintangan haus dan keliatan yang baik, jadi tali pinggang keluli mesti dirawat haba untuk mendapatkan prestasi keseluruhan yang baik. Rajah 12-59 ialah gambarajah skematik peralatan rawatan haba aruhan untuk jalur keluli. Jalur keluli dipanaskan kepada suhu pelindapkejutan oleh induktor pertama, dan dipadamkan oleh muncung 7; induktor kedua 8 dibaja dan dipanaskan, dan kemudian disejukkan dengan udara. Apabila jalur keluli disejukkan di bawah 200°C, muncung 10 menyembur air untuk Sejukkan pantas ke suhu bilik.

Rajah 12-59 Peralatan rawatan haba aruhan jalur keluli

1—Kekili hantar 2-Tali pinggang keluli 3-Roda panduan 4- Kekili ambil 5—Aruh pemanasan pelindapkejutan

6-Inverter 7—Nozzle 8-Temp heating sensor 9-Inverter 10—Nozzle

For a standard size steel belt used as a band saw, its moving speed can exceed 8m/min, and the power of the high-frequency generator is 10-30kW.

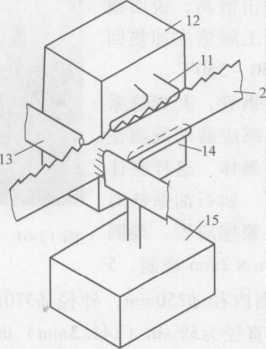

When the steel strip sent out by the reel has cut serrations, a serrated tip quenching equipment can be placed between the nozzle 10 and the take-up reel 4. The quenching equipment includes an inductor 11 and a quenching nozzle 13 (see Figure 12- 60) The sensor 11 heats the serration tip at a temperature higher than the Curie point, and heats the recessed part between the two teeth at a temperature lower than the Curie point. The hardness of the serration tip can reach 65RC, and it is recessed between two consecutive teeth. The hardness of the part is maintained at the hardness after tempering in the inductor 8.

In some cases, when passing through the sensor 11 and entering the nozzle 13, the steel strip is slightly deformed. In order to avoid this deformation, the sensor 14 is installed on the opposite side of the sensor 11 to be lower than the Curie point. The temperature of the saw blade on the opposite side of the tooth is heated.

Kekerapan penjana yang dibekalkan untuk pemanasan pelindapkejutan hendaklah lebih tinggi daripada kekerapan arus yang digunakan untuk pemanasan pembajaan.

Figure 12-60 Steel band saw tooth induction heating quenching

H—Pearuh 12—Penyongsang 13—Nozel pelindapkejutan 14—Pearuh 15—Penyongsang