- 04

- Jan

Application of High Frequency Quenching Equipment in Pressure Quenching

Aplicarea High Frequency Quenching Equipment in Pressure Quenching

Aplicarea High Frequency Quenching Equipment in Pressure Quenching

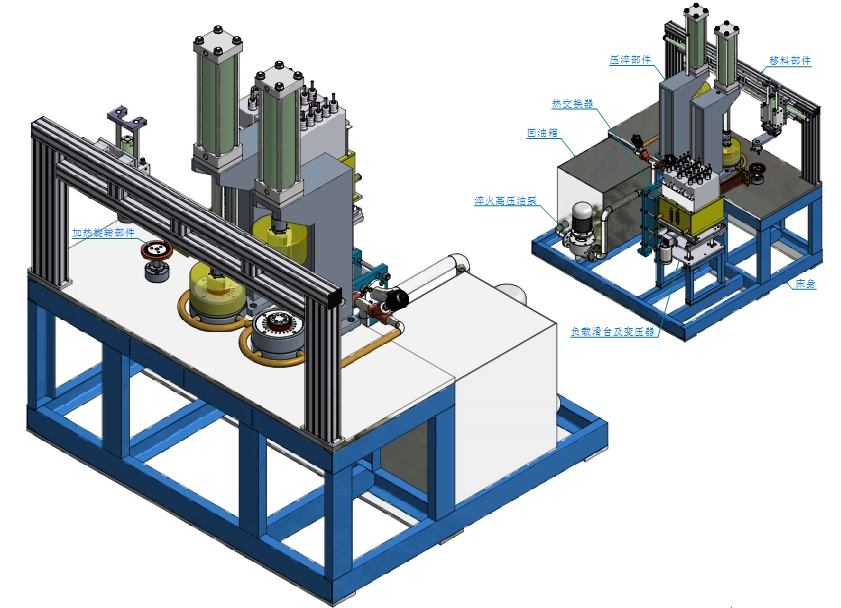

High-frequency quenching equipment is an integrated, multi-functional, mechatronics machining center, composed of seven major parts: power supply system, press quenching machine tool, central control system, working condition management system, power water cooling system, workpiece cooling system and load system .

1. The power supply system is mainly composed of voltage regulation integrated components, rectifier integrated components, oscillating inverter integrated components, tank circuit matching integrated components, output load integrated components and loop control integrated components. The layout is reasonable, the wiring is neat, and the electrical clearance is standardized.

2. The transmission system is mainly composed of CNC control components, servo execution components, lifting mechanism, and transmission body parts. The mechanical drive adopts precision ball screw, and the mechanical drive adopts Siemens servo motor. The equipment has anti-rust, anti-magnetic, anti-leakage, anti-electromagnetic interference and other properties.

The output part is made of high-quality anti-radiation aluminum alloy composite materials, the main frame is made of high-quality anti-corrosion and anti-rust industrial aluminum profiles, and the observation operation window is made of composite shielding glass.

3. The central control system adopts a touch screen man-machine interface, which can visually display the working status of the system, and the transmission control part adopts a numerical control system, which can compile and store a variety of heat treatment process programs according to the requirements of different workpieces. Heating, spraying, and time control are integrated, with a high degree of automation. The start button is externally led for easy operation.

4. The CMS working condition system compares the power supply parameters (grid current, power, heating time, quenching liquid temperature, etc.) with the given values through signal acquisition, processing, and feedback, and judges whether the heating conditions are normal. When the power supply parameters exceed the set upper and lower limits, the equipment will send out a processing alarm signal to facilitate the distribution of unqualified parts. Power parameters can be recorded and downloaded, which is convenient for users to back up.

5. Power water cooling system/workpiece water cooling system

Use high-efficiency turbo compressors. The entire set of refrigeration accessories and electrical systems of the product are selected from internationally well-known brand products, adopting a platform design, reasonable matching of components, compact structure, sophisticated design, and exquisite appearance. The electrical cooling system uses high-temperature hoses, and the electrical appliances and quenching liquid water tanks require the highest The liquid level protection device prevents the water level or the oil level from overflowing when the water level is too high.

It adopts one-button boot, and the operation is all convenient.

It has the characteristics of high precision, stable performance, fast cooling speed, low noise, safety and reliability. The heat exchanger with unique performance can meet the requirements of industrial environment, anti-dust, oil mist, corrosion resistance, and small wind resistance; it has a fault self-diagnosis and alarm function, which displays the fault content through graphics and characters, and sends out an alarm signal.

6. Load system

The sensor is made according to the drawing requirements provided by Party A and confirmed by Party A. The single-sided blind hole sensor strives for further improvement.