- 04

- Jan

Ukusetshenziswa Kwezisetshenziswa Zokucisha Imvamisa Ephakeme Ekuqedeni Ukucindezela

Isicelo se Izisetshenziswa zokucisha imvamisa ephezulu Ekucimeni Ingcindezi

Isicelo se Isisetshenziswa Sokucisha Imvamisa Ephakeme Ekucimeni Ingcindezi

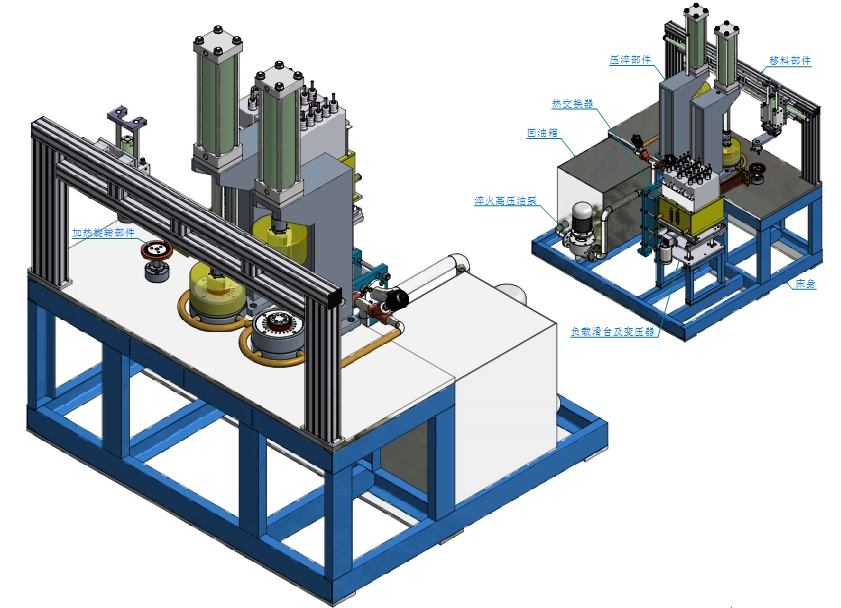

Imishini yokucisha imvamisa ephezulu iyisikhungo esididiyelwe, esisebenza ngezindlela eziningi, se-mechatronics, esakhiwe izingxenye eziyisikhombisa ezinkulu: uhlelo lokuphakela amandla, ithuluzi lomshini wokucisha umshini wokucindezela, uhlelo lokulawula olumaphakathi, uhlelo lokuphatha isimo sokusebenza, uhlelo lokupholisa amanzi kagesi, uhlelo lokupholisa ucezu lokusebenza kanye uhlelo lokulayisha .

1. Uhlelo lokunikezwa kwamandla lwakhiwe ngokuyinhloko izingxenye ezididiyelwe zokulawulwa kwamandla kagesi, izingxenye ezididiyelwe zokulungisa kabusha, izingxenye ezihlanganisiwe ze-oscillating inverter, i-tank circuit ehambisana nezingxenye ezididiyelwe, izingxenye ezididiyelwe zomthwalo ophumayo kanye nezingxenye ezididiyelwe zokulawula iluphu. Isakhiwo sinengqondo, izintambo zihlanzekile, futhi imvume kagesi isezingeni.

2. Isistimu yokudlulisa ngokuyinhloko yakhiwe izingxenye zokulawula ze-CNC, izingxenye ze-servo execution, indlela yokuphakamisa, kanye nezingxenye zomzimba zokudlulisela. Idrayivu yemishini isebenzisa isikulufu sebhola esinembayo, futhi idrayivu yemishini isebenzisa i-Siemens servo motor. Imishini ine-anti-rust, anti-magnetic, anti-leakage, ukuphazamiseka kwe-anti-electromagnetic nezinye izakhiwo.

Ingxenye ephumayo yenziwe ngezinto ezihlanganisiwe ze-anti-radiation aluminium alloy composite, ifreyimu eyinhloko yenziwe ngamaphrofayili e-aluminium yezimboni ezilwa nokugqwala aphezulu, futhi iwindi lokubuka lenziwe ngengilazi evikelayo eyinhlanganisela.

3. Isistimu yokulawula emaphakathi yamukela isikrini sokuthinta somshini womshini womuntu, ongabonisa ngokubukeka isimo sokusebenza sohlelo, futhi ingxenye yokulawula ukudlulisa yamukela uhlelo lokulawula izinombolo, olungahlanganisa futhi lugcine izinhlelo ezihlukahlukene zenqubo yokwelashwa kokushisa ngokusho. ngezidingo zezinhlelo zokusebenza ezahlukahlukene. Ukushisisa, ukufutha, nokulawula isikhathi kuhlanganiswe, ngezinga eliphezulu lokuzishintsha. Inkinobho yokuqala iholwa ngaphandle ukuze isebenze kalula.

4. Uhlelo lwesimo sokusebenza se-CMS luqhathanisa amapharamitha wokuphakela amandla (igridi yamanje, amandla, isikhathi sokushisisa, izinga lokushisa loketshezi lokucisha, njll.) namanani anikeziwe ngokutholwa kwesignali, ukucutshungulwa, kanye nempendulo, futhi liyahlulela ukuthi izimo zokushisisa ziyini. evamile. Lapho amapharamitha wokuphakela amandla edlula imikhawulo emisiwe engaphezulu nephansi, okokusebenza kuzothumela isignali ye-alamu yokucubungula ukuze kube lula ukusatshalaliswa kwezingxenye ezingafanelekile. Imingcele yamandla ingarekhodwa futhi ilandwe, okulungele abasebenzisi ukwenza ikhophi yasenqolobaneni.

5. Isistimu yokupholisa amanzi yamandla/isistimu yokupholisa amanzi yocezu lokusebenza

Sebenzisa ama-turbo compressors asebenza kahle kakhulu. Lonke isethi yezesekeli zesiqandisi kanye nezinhlelo zikagesi zomkhiqizo zikhethwa emikhiqizweni yohlobo eyaziwa emhlabeni wonke, zamukela umklamo weplathifomu, ukufanisa okunengqondo kwezingxenye, ukwakheka okuhlangene, ukwakheka okuyinkimbinkimbi, nokubukeka okuhle. Isistimu yokupholisa kagesi isebenzisa amapayipi okushisa aphezulu, futhi izinto zikagesi kanye namathangi amanzi awuketshezi acishayo adinga okuphezulu kakhulu Umshini wokuvikela izinga loketshezi uvimbela izinga lamanzi noma izinga likawoyela ukuthi lingachichima lapho izinga lamanzi liphezulu kakhulu.

Isebenzisa ibhuthi yenkinobho eyodwa, futhi ukusebenza konke kulula.

Inezici zokunemba okuphezulu, ukusebenza okuzinzile, isivinini sokupholisa ngokushesha, umsindo ophansi, ukuphepha nokuthembeka. Umshini wokushisa onokusebenza okuyingqayizivele ungahlangabezana nezidingo zendawo yezimboni, ukulwa nothuli, inkungu kawoyela, ukumelana nokugqwala, nokumelana komoya omncane; inomshini wokuzihlolela iphutha kanye nomsebenzi we-alamu, obonisa okuqukethwe okuyiphutha ngezithombe nezinhlamvu, futhi ithumele isignali ye-alamu.

6. Uhlelo lokulayisha

Inzwa yenziwe ngokwezidingo zomdwebo ezihlinzekwe yi-Party A futhi yaqinisekiswa yi-Party A. Inzwa yembobo eyimpumputhe enohlangothi olulodwa ilwela ukuthuthuka okwengeziwe.