- 06

- Dec

Качество закалки с индукционным нагревом распредвала

Качество закалки с индукционным нагревом распредвала

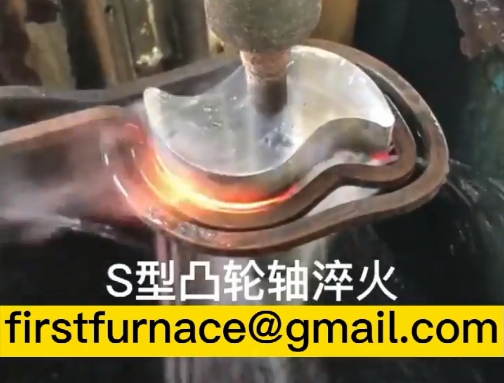

After the 8 cams are cooled by induction heating and immersion, the depth and quenching hardness of the hardened layer are shown in Table 3 . It can be seen from Table 3 that both indicators meet the technical requirements of the product map. It can be seen from the cross-sectional view of the quenched part of the cam that the hardened layer is uniform and the position is correct.

Table 3 Camshaft quenching hardness and depth of hardened layer

| Cam number | Твердость закалки HRC | Глубина упрочняющего слоя / мм | |

| Чаевые | Базовый круг | ||

| 1 | 51 53.5 55 | 7.8 | 5.7 |

| 2 | 52 54 54 | 7.2 | 6.0 |

| 3 | 55 55.5 53 | 10.0 | 6.5 |

| 4 | 53 53 56 | 7.5 | 6.4 |

| 5 | 50 51 52.5 | 9.6 | 7.3 |

| 6 | 56 55 56 | 10.3 | 7.5 |

| 7 | 54 52 54 | 10.8 | 7.7 |

| 8 | 52 50 52 | 9.5 | 7.0 |

After the camshaft is quenched, the increased value of radial runout is tested to be 0.15mm , which can meet the requirements of the next process without straightening. The temperature of the quenching medium is in the range of 10°C-40°C , and the quenched cam has no quenching cracks through fluorescent inspection.

https://songdaokeji.cn/14033.html

https://songdaokeji.cn/14035.html

https://songdaokeji.cn/14037.html