- 21

- Sep

Gangdi coreless induction inkcazo yobugcisa beziko

Gangdi coreless i-induction isithando sobugcisa Inkcazo

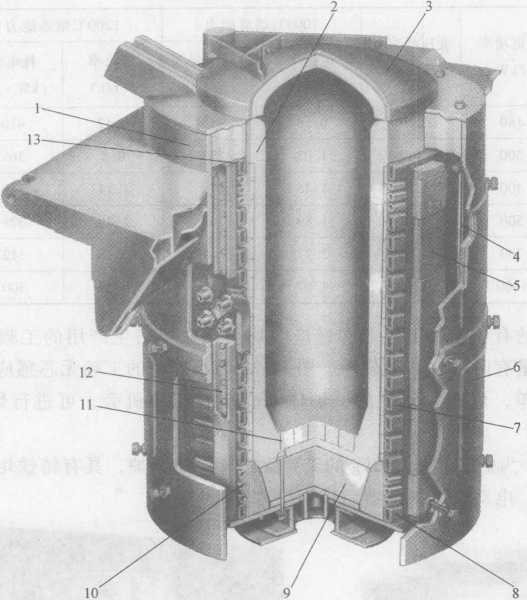

Kwiminyaka yakutshanje, iqokobhe elikhulu lentsimbi yokufaka i-coreless furnaces eyenziwe ziinkampani zokufudumeza zangaphandle zenze uphuculo olukhulu kulwakhiwo lomzimba wesithando somlilo. Umzobo we-12-83 ngumbono we-cross-sectional we-steel shell coreless induction furnace.

Iqokobhe lensimbi coreless induction eziko lithelekiswa nesakhelo sentsimbi esaveliswe ngaphambili. Ngenxa yokuba iqokobhe lesithando somlilo liqengqeleke yintsimbi eshinyeneyo, linika amandla kuwo wonke umzimba weziko. Imagnethi evuzayo igxininiswe ngokuthe ngqo kwiqokobhe lensimbi kwaye ibonelela ngenkxaso eyomeleleyo kwikhoyili ye-induction. Ngethuba lokuthotywa kwesithando somlilo, bonke ubunzima buqhutyelwa kwigobolondo yensimbi. Nokuba umngxuma ogqithisiweyo kwiqokobhe lensimbi mkhulu, umzimba wesithando somlilo unamandla aqinileyo kwaye unqanda ukuguqulwa okubangelwa kukuthotywa kwesithando somlilo.

Umfanekiso we-12-83 Umzimba wesithando somlilo weqokobhe lentsimbi enzima

1 iqokobhe leziko 2 iqokobhe leziko eliqhekeziweyo 3 isigqubuthelo somlilo 4 iqhina leqhina 5-umazibuthe

6-Isigqubuthelo somngxuma 7-i-coil yokungenisa 8-ikhonkco lobhedu elipholiswe ngamanzi 9 isitena esinqabileyo

10—Umbhobho wokupholisa amanzi 11—Isixhobo sokukhusela ukuvuza komhlaba 12—Ikholamu ye-Bakelite 13—ibhodi yokugquma ubushushu.

Ubomi benkonzo yomgca wesithando somlilo bunokwandiswa. Ekubeni igobolondo yensimbi ivaliwe kwaye i-coil induction ivaliwe, ingxolo yokusebenza iyancitshiswa kakhulu ngexesha lokuqhaqha, kwaye isinyithi esitshisiweyo asikwazi ukuchukumisa i-coil induction, ukuphepha ngokupheleleyo umonakalo kwi-coil induction.

Ikhoyili yokungeniswa ilinyazwa yityhubhu yobhedu etyebileyo etyebileyo enoxande kunye nomsantsa othile phakathi kokujika. Ityhubhu yobhedu esulungekileyo idityaniswe nge-stud ukuba ilungiswe kunye nekholamu ye-bakelite ukuze kuqinisekiswe ubungakanani be-gap inter-turn of coil. Ikhoyili ayilulanga ukuba ikhubazeke, kwaye i-gap inter-turn of the coil inokwenza umphunga wamanzi kwi-lining material uguquguquke lula. Kukho imibhobho epholileyo yamanzi enxeba kunye nemibhobho yensimbi engenasici kuzo zombini iziphelo zekhoyili, engakwaziyo ukufezekisa injongo yokushisa okulinganayo kwesithando somlilo, kodwa nokunciphisa ukwanda kwe-thermal. Phezulu nasezantsi kwekhoyili, kukho umsesane wobhedu ococekileyo opholileyo wamanzi, ovelisa i-reverse magnetic flux ngexesha lokusebenza, okunciphisa i-demagnetization kuzo zombini iziphelo zekhoyili kwaye inqande ukufudumeza kwegobolondo lensimbi. Isixhobo sokucinezela ikhoyili sithintela ukungcangcazela. Yayisakuba sisakhiwo sasentwasahlobo, kodwa ngoku sithatyathelwa indawo yintonga yokutsala ekulula ukuyilungisa. Umzimba ongenekayo umile okwe-arc kwaye unokungena kakuhle kunye nekhoyili. I-spacer ekhuselayo ibekwe phakathi kwemagnethi ekwazi ukungena kunye nekhoyili ukunciphisa ingxolo kunye nokungcangcazela. Kukho ipleyiti eshinyeneyo ye-aluminiyam emazantsi eziko ukunqanda ukufudumeza ngaphantsi kweziko, kwaye umzantsi weziko uvulekile, kulula ukukhupha umoya, ukunqanda ukufumba kokufuma, kwaye kwimeko yokuvuza kwesithando somlilo, kunoko. kwakhona ukunciphisa iqondo umonakalo.

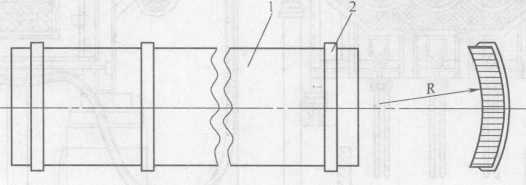

Umzobo we-12-84 ubonisa umqhubi wemagnethi ocinezelweyo owenziwe nge-arc, ipleyiti yoxinzelelo eyenziwe ngentsimbi engenazibuthe, edityaniswe kunye neshiti lensimbi yesilicon. Umqhubi kazibuthe osetyenziswe ngaphambili unemingxuma egqobhozelwe kwiphepha lentsimbi yesilicon. Emva kokuba ishidi lensimbi ye-silicon i-laminated, ixinzelelwe ngeebholiti zetsimbi ezingenazibuthe kunye namantongomane, kwaye akunakwenzeka ukuyenza ibe yi-arc shape.

Umzobo 12-84 Umazibuthe obambekayo ongenekayo

I-1-I-Silicon steel sheet 2-Cofa ipleyiti