- 21

- Sep

Incazelo yezobuchwepheshe yesithando somlilo se-Gangdi

Gangdi coreless isithando somlilo sokungeniswa incazelo

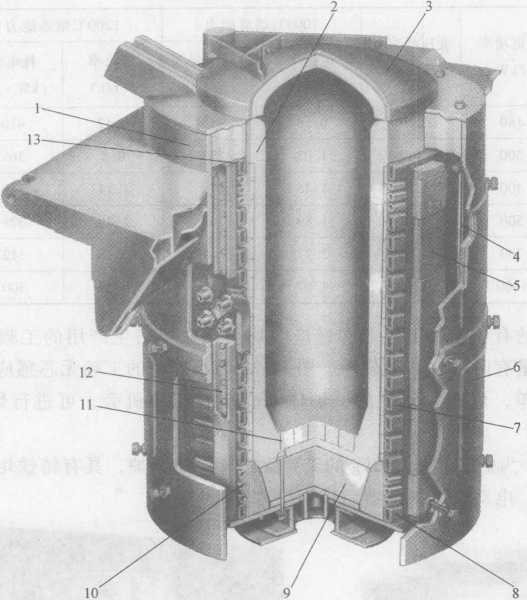

Eminyakeni yamuva nje, iziko elikhulu lensimbi elinomthamo omkhulu we-coreless induction ekhiqizwa izinkampani zokufudumeza zangaphandle zenze intuthuko enkulu esakhiweni somzimba wesithando somlilo. Umfanekiso 12-83 uwukubuka okuphambene kwesithando somlilo segobolondo lensimbi.

Isithando somlilo sokungeniswa kwegobolondo lensimbi siqhathaniswa nesithando somlilo esifakwe ngaphambili sohlaka lwensimbi olungenasisekelo. Ngenxa yokuthi igobolondo lesithando somlilo ligoqwe ipuleti lensimbi eliwugqinsi, linikeza amandla kuwo wonke umzimba wesithando somlilo. Uzibuthe okwazi ukungena ugxile ngokuqondile egobolondweni lensimbi futhi unikeza ukusekela okuqinile kwekhoyili yokungeniswa. Ngesikhathi sokutsheka kwesithando somlilo, sonke isisindo sithwalwa egobolondweni lensimbi. Ngisho noma imbobo yokulungisa phezu kwegobolondo lensimbi inkulu, umzimba wesithando somlilo unamandla aqinile futhi ugwema ukuguqulwa okubangelwa ukutshekiswa kwesithando somlilo.

Umfanekiso 12-83 Umzimba wesithando somlilo wegobolondo lensimbi esindayo

1 igobolondo lesithando somlilo 2 ulayini womlilo ophihliziwe 3 isembozo somlilo 4 induku yokubopha 5-umazibuthe

Ikhava yembobo engu-6 7—ikhoyili yokungeniswa 8—indandatho yethusi epholile epholile ngamanzi 9 isitini esikhanyelayo esimise okukhethekile

10—Ipayipi elipholisa amanzi 11—Idivaysi yokuvikela ukuvuza komhlaba 12—Ikholomu ye-Bakelite 13—ibhodi lokuvikela elingashisi ukushisa

Impilo yesevisi ye-lining yesithando somlilo ingandiswa. Njengoba igobolondo lensimbi livaliwe futhi ikhoyili yokungeniswa ivaliwe, umsindo osebenzayo uyancipha kakhulu ngesikhathi sokuncibilika, futhi insimbi efafaziwe ayikwazi ukuthinta ikhoyili yokungeniswa, igweme ngokuphelele umonakalo wekhoyili yokungeniswa.

Ikhoyili yokungeniswa ilinyazwa ishubhu yethusi eliqinile elingunxande elinesikhala esithile phakathi kwamajika. Ishubhu yethusi ehlanzekile ishiselwe nge-stud okufanele ihlanganiswe nekholomu ye-bakelite ukuze kuqinisekiswe usayizi wegebe eliphakathi nendawo lekhoyili. Ikhoyili akulula ukuthi igogeke, futhi igebe phakathi kokuphenduka kwekhoyili lingenza ukuba umhwamuko wamanzi odongeni uguquke kalula. Kukhona amapayipi amanzi apholisekile amapayipi ensimbi engagqwali emikhawulweni yomibili ikhoyili, engakwazi nje ukufeza inhloso yokushisa kwesithando somlilo, kodwa futhi kunciphise ukunwetshwa okushisayo. Phezulu nangaphansi kwekhoyili, kunendandatho yethusi epholile epholile ngamanzi, ekhiqiza i-flux kazibuthe ehlehlayo ngesikhathi sokusebenza, enciphisa ukuphuma kuzibuthe kuzo zombili iziphetho zekhoyili futhi igweme ukushisisa kwegobolondo lensimbi. Idivayisi yokucindezela ikhoyili ivimbela ukudlidliza. Kwakuyisakhiwo sasentwasahlobo, kodwa manje sesithathelwa indawo induku yokudonsa okulula ukuyilungisa. Umzimba okwazi ukungena ungene umise okwe-arc futhi ungalingana kahle nekhoyili. I-spacer evikelayo ifakwa phakathi kukazibuthe okwazi ukungena kanye nekhoyili ukuze kuncishiswe umsindo nokudlidliza. Kunepuleti le-aluminium eliwugqinsi ezansi kwesithando ukuze kugwenywe ukushisa ngaphansi kwesithando somlilo, futhi phansi kwesithando somlilo kuvulekile, kungene umoya kalula, ukuze kugwenywe ukunqwabelana komswakama, futhi uma kwenzeka ukuvuza kwesithando somlilo, kungakwazi. futhi ukunciphisa izinga lomonakalo.

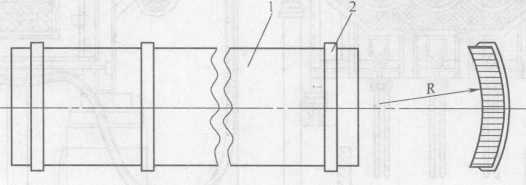

Umfanekiso 12-84 ubonisa i-conductor kazibuthe ecindezelwe emise okwe-arc, ipuleti lokucindezela elenziwe ngensimbi engagqwali engeyona enozibuthe, eshiselwe kanye neshidi lensimbi ye-silicon. I-conductor kazibuthe esetshenziswe ngaphambili inezimbobo ezibhotshozwe eshidini lensimbi ye-silicon. Ngemuva kokuthi ishidi lensimbi ye-silicon lifakwe laminated, licindezelwa ngamabhawodi ensimbi engenazibuthe namantongomane, futhi akunakwenzeka ukulenza libe yi-arc shape.

Umfanekiso 12-84 Uzibuthe okwazi ukungena ngaphakathi

1—I-Silicon steel sheet 2—Cindezela ipuleti