- 05

- Nov

New technology of induction heating pipe bending

New technology of induction heating pipe bending

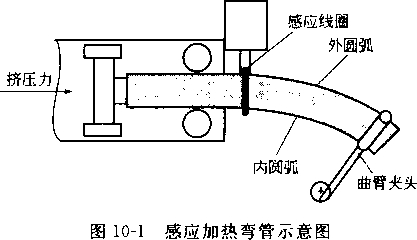

The schematic diagram of the induction heating elbow is shown in the figure. When bending the pipe, place the induction coil on a specific part of the steel pipe. One end of the steel pipe is placed on the connector supported by the positioning and guiding spoke wheels, and the other end is fixed by a rotatable crank chuck. When the induction coil is fed with an intermediate frequency current, it quickly heats the local steel pipe to a predetermined temperature, and at the same time, the steel pipe begins to thermally deform under the action of the squeezing force and deform along a predetermined arc. The deformed elbow is quenched and cooled. The quenching medium is mostly cooled by water spray or cold air. The thermal deformation speed is slow, and the induction coil maintains a stable heating temperature. The bending and quenching process are carried out in sequence.

It can be seen from the hot bending deformation process of the steel pipe that the outer arc of the steel pipe is subjected to tensile stress, and the pipe wall becomes thin; the inner arc is subjected to compressive stress, and the pipe wall becomes thicker; the side deformation of the steel pipe is different from the outer arc and the inner arc . The entire elbow section is subjected to a variety of complex stresses, and the mechanical properties of different parts of the steel pipe after heat treatment will also have obvious differences.