- 01

- Apr

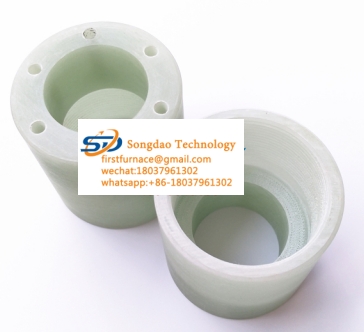

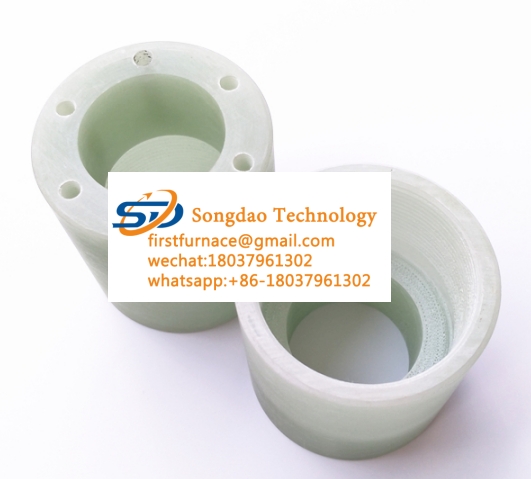

Electroreactor insulation cylinder

Electroreactor insulation cylinder

The reactor insulator, also known as the resistance shell and the reactor insulation bracket, adopts the epoxy resin insulation cylinder shell, with sufficient electrical and mechanical strength, necessary heat dissipation capacity and the margin of oil heat expansion and cold shrinkage.The reactor housing comes with the base and the upper end of another section.The shell is painted with white or orange insulated paint.The reactor insulation shell can be free and convenient to stack and lift.

Two, product performance

Tabela parametara performansi izolacionog cilindra od epoksi fiberglasa klase H

| Ne | Naziv indikatora | zahtjevi | jedinica | Indeksna vrijednost |

| 1 | gustoća | G/cm 3 | 1.9-2.0 | |

| 2 | Intenzitet savijanja | Ni manje ni više | Mpa | 320 |

| 3 | Snaga otpornosti na pritisak | Ni manje ni više | Mpa | 200 |

| 4 | Čvrstoća protiv smicanja | Ni manje ni više | Mpa | 32 |

| 5 | srednji faktor gubitka (50Hz) | Ne veće od | 0.02 | |

| 6 | Dielektrična konstanta | 3 ~ 6 | ||

| 7 | Kada je zapreminska otpornost normalna | Ni manje ni više | Qm | 10X1011 |

| Nakon potapanja | 10X109 | |||

| 8 | Kada se paralelni sloj kreće prema normalnom otporu izolacije | Ni manje ni više | Q | 10X1011 |

| Nakon potapanja | 10X109 | |||

| 9 | Otpor površinskog napona

(otporan na pritisak lmin,30mm u vazduhu) |

KV | 14 | |

| 10 | Napon otpora vertikalnog smjera sloja od 8> 3mm | KV | 20 | |

| 11 | Napon otporan na paralelni sloj (razmak od 25 mm) | Ni manje ni više | KV | 50 |

| 12 | Otpor izolacije | Ni manje ni više | MQ | 5X104 |

| 13 | Rastojanje otpora napona industrijske frekvencije (po tehnologiji korisnika

Uslovi) |

Ni manje ni više | KV | 80 |

| 14 | Otpornost na toplotu | Ni manje ni više | ° C | 180 |

| 15 | Srednja temperatura termičke deformacije | Ni manje ni više | ° C | 250 |

Three, product characteristics

The insulation shell of the reactor is made of high quality glass fiber soaked with high-low viscosity and high-temperature epoxy resin and cross-wound along the axial direction under the control of the microcomputer. It is a high quality insulation pipe for manufacturing high voltage, composite hollow sleeve of high-high voltage SF6 high voltage electrical appliances and current transformer.The products are widely used for making the main insulation materials for high voltage products such as reactor insulation supports, outdoor high voltage fuses, lightning arresters, load split switches, dry and oil immersed transformers, railway locomotive transformers, SF6 inductors, capacitors and test devices.Product insulation temperature resistance grade H, C, etc., product implementation standard GB/T23100-2008.

IV. Product mold specifications