- 01

- Apr

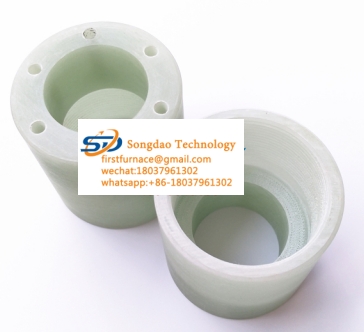

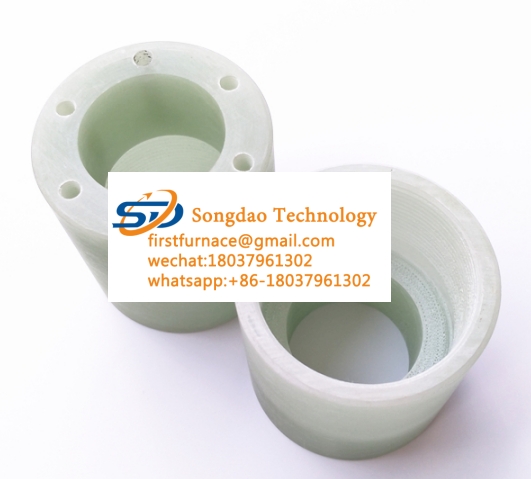

Electroreactor insulation cylinder

Electroreactor insulation cylinder

The reactor insulator, also known as the resistance shell and the reactor insulation bracket, adopts the epoxy resin insulation cylinder shell, with sufficient electrical and mechanical strength, necessary heat dissipation capacity and the margin of oil heat expansion and cold shrinkage.The reactor housing comes with the base and the upper end of another section.The shell is painted with white or orange insulated paint.The reactor insulation shell can be free and convenient to stack and lift.

Two, product performance

Performance parameter table of Class H epoxy fiberglass insulation cylinder

| No | Indicator name | Requirements | Unit | Index value |

| 1 | Density | G/cm 3 | 1.9-2.0 | |

| 2 | Intensity of bending | No less than | Mpa | 320 |

| 3 | Pressure resistance strength | No less than | Mpa | 200 |

| 4 | Anti-shear strength | No less than | Mpa | 32 |

| 5 | Medium Loss Factor (50Hz) | No greater than | 0.02 | |

| 6 | The dielectric constant | 3~6 | ||

| 7 | When the volume resistivity is normal | No less than | Qm | 10X1011 |

| After immersion | 10X109 | |||

| 8 | When the parallel layer moves toward the normal insulation resistance | No less than | Q | 10X1011 |

| After immersion | 10X109 | |||

| 9 | Surface voltage resistance

(Pressure-resistant lmin,30mm in the air) |

KV | 14 | |

| 10 | Vertical layer direction resistance voltage of 8> 3mm | KV | 20 | |

| 11 | Parallel layer-resistant voltage (25mm spacing) | No less than | KV | 50 |

| 12 | Insulation resistance | No less than | MQ | 5X104 |

| 13 | Industrial frequency voltage resistance distance (by customer technology

Requirements) |

No less than | KV | 80 |

| 14 | Heat resistance | No less than | °C | 180 |

| 15 | Meverage thermal deformation temperature | No less than | °C | 250 |

Three, product characteristics

The insulation shell of the reactor is made of high quality glass fiber soaked with high-low viscosity and high-temperature epoxy resin and cross-wound along the axial direction under the control of the microcomputer. It is a high quality insulation pipe for manufacturing high voltage, composite hollow sleeve of high-high voltage SF6 high voltage electrical appliances and current transformer.The products are widely used for making the main insulation materials for high voltage products such as reactor insulation supports, outdoor high voltage fuses, lightning arresters, load split switches, dry and oil immersed transformers, railway locomotive transformers, SF6 inductors, capacitors and test devices.Product insulation temperature resistance grade H, C, etc., product implementation standard GB/T23100-2008.

IV. Product mold specifications