- 01

- Apr

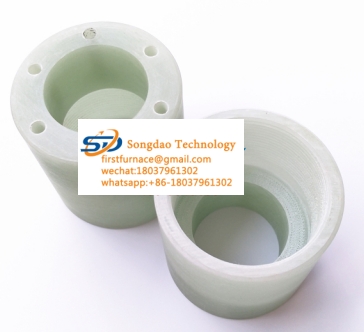

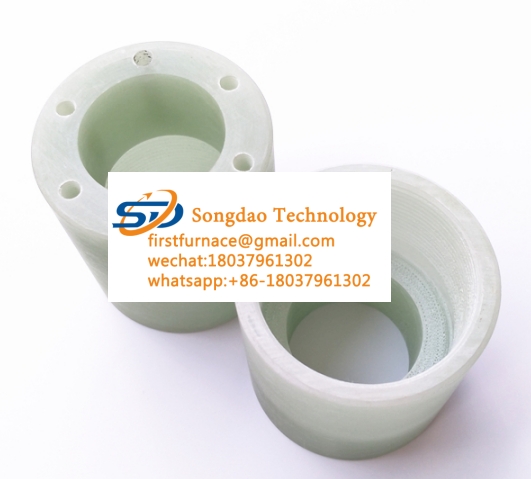

Electroreactor insulation cylinder

Electroreactor insulation cylinder

The reactor insulator, also known as the resistance shell and the reactor insulation bracket, adopts the epoxy resin insulation cylinder shell, with sufficient electrical and mechanical strength, necessary heat dissipation capacity and the margin of oil heat expansion and cold shrinkage.The reactor housing comes with the base and the upper end of another section.The shell is painted with white or orange insulated paint.The reactor insulation shell can be free and convenient to stack and lift.

Two, product performance

Ytelsesparametertabell for klasse H epoxy glassfiberisoleringssylinder

| Nei | Indikatornavn | Krav | Enhet | Indeksverdi |

| 1 | Tetthet | G/cm 3 | 1.9-2.0 | |

| 2 | Bøyningsintensitet | Ikke mindre enn | MPA | 320 |

| 3 | Trykkmotstandsstyrke | Ikke mindre enn | MPA | 200 |

| 4 | Anti-skjærstyrke | Ikke mindre enn | MPA | 32 |

| 5 | Middels tapsfaktor (50 Hz) | Ikke større enn | 0.02 | |

| 6 | Den dielektriske konstanten | 3 ~ 6 | ||

| 7 | Når volumresistiviteten er normal | Ikke mindre enn | Qm | 10X1011 |

| Etter nedsenking | 10X109 | |||

| 8 | Når det parallelle laget beveger seg mot normal isolasjonsmotstand | Ikke mindre enn | Q | 10X1011 |

| Etter nedsenking | 10X109 | |||

| 9 | Overflatespenningsmotstand

(Trykkbestandig lmin, 30 mm i luften) |

KV | 14 | |

| 10 | Vertikal lagretningsresistensspenning på 8> 3 mm | KV | 20 | |

| 11 | Parallell lagbestandig spenning (25 mm avstand) | Ikke mindre enn | KV | 50 |

| 12 | Isolasjonsmotstand | Ikke mindre enn | MQ | 5X104 |

| 13 | Industriell frekvensspenningsmotstandsavstand (etter kundeteknologi

Krav) |

Ikke mindre enn | KV | 80 |

| 14 | Varmebestandighet | Ikke mindre enn | ° C | 180 |

| 15 | Drikk termisk deformasjonstemperatur | Ikke mindre enn | ° C | 250 |

Three, product characteristics

The insulation shell of the reactor is made of high quality glass fiber soaked with high-low viscosity and high-temperature epoxy resin and cross-wound along the axial direction under the control of the microcomputer. It is a high quality insulation pipe for manufacturing high voltage, composite hollow sleeve of high-high voltage SF6 high voltage electrical appliances and current transformer.The products are widely used for making the main insulation materials for high voltage products such as reactor insulation supports, outdoor high voltage fuses, lightning arresters, load split switches, dry and oil immersed transformers, railway locomotive transformers, SF6 inductors, capacitors and test devices.Product insulation temperature resistance grade H, C, etc., product implementation standard GB/T23100-2008.

IV. Product mold specifications