- 03

- Dec

Copper tube induction cua sov nruam annealing ntau lawm kab

Copper tube induction cua sov nruam annealing ntau lawm kab

Kev piav qhia ntawm cov yam ntxwv siab heev ntawm tag nrho lub tshuab:

Lub raj tooj liab induction cua sov nruam annealing ntau lawm kab adopts thoob ntiaj teb advanced series inverter intermediate zaus induction cua sov fais fab mov. Piv nrog rau cov khoom siv hluav taws xob sib txuas, kev txuag hluav taws xob tuaj yeem ncav cuag 20%. Lub zog noj yog tswj ntawm 330kwh / T. Lub series inverter intermediate zaus fais fab mov yog heev haum rau tooj liab raj induction cua sov. Nyob rau hauv lub tooj liab raj induction cua sov, lub hwj chim yam yuav ncav cuag 0.98. Kev tiv thaiv muaj nuj nqi ua tiav thiab cov xim kov npo zaub. Qhov no series inverter intermediate zaus annealing rauv muaj nitrogen tiv thaiv system. Lub annealed tooj liab raj yog ci thiab huv si, uas yog ib tug high-efficiency zog-txuag high-tech khoom.

1. Tag nrho cov txheej txheem annealing ntawm cov khoom yog muab tso rau hauv ib qho chaw tiv thaiv, qhov chaw ntawm lub annealed workpiece yog ci thiab tsis-oxidized, thiab nto ntawm cov hlau tsis decarburized.

2. Vim muaj zog convection ncig ntawm cov roj tiv thaiv nyob rau hauv lub cub tawg, lub cub tawg kub yog ib yam, yog li ntawd qhov kub ntawm qhov sib txawv ntawm cov khoom nyob rau hauv lub cub tawg yog nyob rau hauv ± 5 ℃; nws tuaj yeem ua kom ntseeg tau tias cov khoom siv annealing ntawm txhua txoj haujlwm yog tib yam hauv cov mos mos thiab tawv, uas yooj yim rau kev ua cov khoom siv ntxiv.

3. Txais ob chav rauv hauv paus cua sov thiab cua txias quasi-nruam kev ua haujlwm hom, cov qauv ntawm lub cub tawg yog kev tshawb fawb thiab tsim nyog, cov nyhuv txuag hluav taws xob yog pom tseeb, kev siv hluav taws xob ib tuj ntawm cov hlau tsis tshua muaj; Lub peev xwm siab tshaj plaws ntawm ib lub cub tawg yog 30 tons, thiab kev ua haujlwm ntau lawm yog siab.

4. Qhov saum npoo ntawm cov khoom siv kho los ntawm hom rauv no yog ci, uas tshem tawm cov txheej txheem pickling, ntxuav qhov chaw ua haujlwm thiab tshem tawm cov kua qaub.

5. Tag nrho cov txheej txheem ntawm cov cuab yeej yog tswj los ntawm lub khoos phis tawj nrog qib siab ntawm automation, uas tuaj yeem ua kom cov khoom zoo thiab kev nyab xeeb ntawm cov khoom siv.

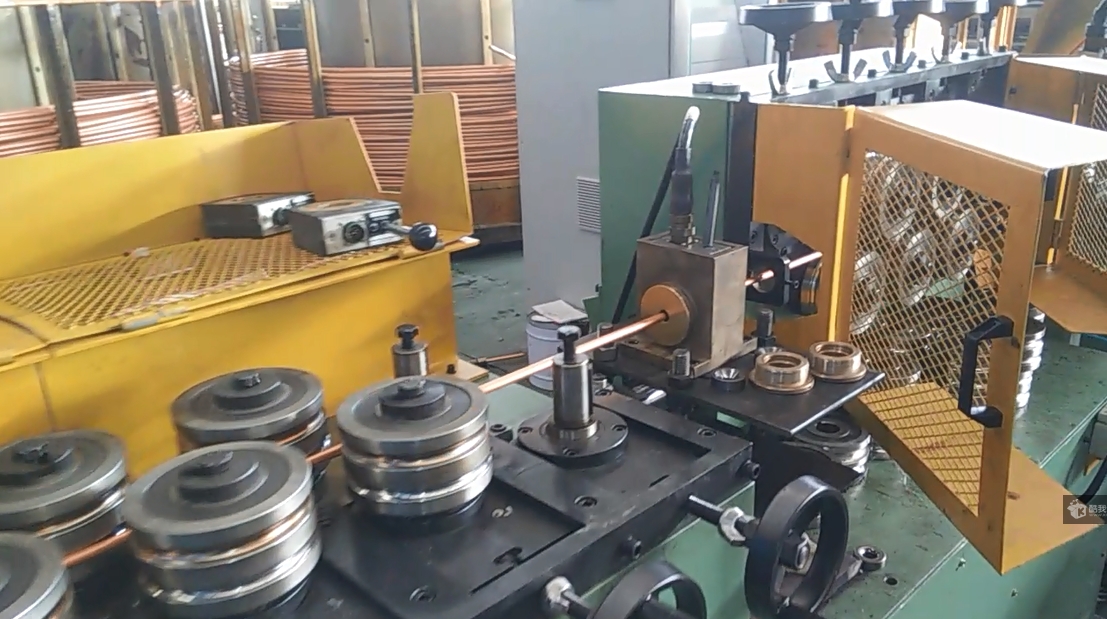

Tshuab qauv

Lub nruam on-line annealing rauv yog tsim los ntawm ib tug discharging mechanism, ib tug clamping thiab kho tus tswv, ib tug cua sov nruab nrab zaus rauv, ib tug on-line circulating cua txias system, ib tug drying mechanism, tensioning mechanism, ib tug txais mechanism thiab auxiliary system ceev ntsuas. ntaus ntawv, thiab lub computer tswj core system. Nyob rau hauv lub nruam on-line annealing unit, lub induction cua sov rauv yog lub hauv paus ntawm kev ua hauj lwm ib txwm ua hauj lwm ntawm tag nrho cov tshuab, thiab lub computer tsis siv neeg tswj qhov system yog cov tswj core.