- 03

- Dec

Ukufudumeza ityhubhu ye-Copper eqhubekayo yokuvelisa i-annealing

Ukufudumeza ityhubhu ye-Copper eqhubekayo yokuvelisa i-annealing

Inkcazo yeempawu eziphambili zomatshini wonke:

Ityhubhu yokungenisa ukufudumeza eqhubekayo yokuvelisa i-annealing ithatha uthotho lwamazwe ngamazwe oluphezulu lwe-inverter intermediate intermediate frequency induction heat supply. Xa kuthelekiswa nonikezelo lwamandla ombane oluhambelanayo, ukonga amandla kunokufikelela kwi-20%. Ukusetyenziswa kwamandla kugcinwa kwi-330kwh/T. Uthotho lwe-inverter intermediate frequency unikezelo lwamandla lulungele kakhulu ukufudumeza ityhubhu yobhedu. Kwi-tube yokufudumala yokufudumala i-tube, into yamandla inokufikelela kwi-0.98. Umsebenzi wokukhusela ugqityiwe kwaye umboniso wesikrini sokuchukumisa umbala. Olu thotho inverter intermediate frequency annealing eziko iqulethe inkqubo nitrogen yokhuseleko. Ityhubhu yobhedu ene-annealed iqaqambile kwaye icocekile, nto leyo iyindlela ephezulu yokonga amandla ezixhobo zobuchwephesha obuphezulu.

1. Yonke inkqubo yokucoca i-annealing yezinto ifakwe kwi-atmosphere ekhuselayo, umphezulu we-workpiece ye-annealed ikhanya kwaye ayinayo i-oxidized, kwaye ubuso bentsimbi abuchithwanga.

2. Ngenxa yokujikeleza okunamandla kwegesi yokukhusela kwisithando somlilo, ukushisa kwesithando somlilo kufana, ukwenzela ukuba ukuhluka kweqondo lokushisa kwezixhobo eziko kungaphakathi kwe-± 5℃; inokuqinisekisa ngokufanelekileyo ukuba i-annealing material kuyo nayiphi na indawo iyafana kwi-soft and hard, ekulungele ukuqhutyelwa phambili kwezinto.

3. Yamkela isiseko sokufudumeza kwesithando somlilo esiphindwe kabini kunye nokupholisa imowudi yokusebenza eqhubekayo, isakhiwo sesithando somlilo singokwesayensi kwaye sinengqiqo, umphumo wokonga amandla uyabonakala, ukusetyenziswa kwamandla ngetoni yentsimbi kuphantsi; ubuninzi bomthamo wesithando somlilo sinye iitoni ezingama-30, kwaye ukusebenza kakuhle kwemveliso kuphezulu.

4. Umphezulu wezinto eziphathwayo ngolu hlobo lwesithando somlilo ukhanya, ophelisa inkqubo yokukhetha, ukucoca indawo yokusebenza kunye nokuphelisa ukungcola kwe-asidi.

5. Isethi yonke yezixhobo ilawulwa yikhompyutheni enezinga eliphezulu lokuzenzekelayo, elinokuqinisekisa ngokufanelekileyo umgangatho wemveliso kunye nokusebenza ngokukhuselekileyo kwezixhobo.

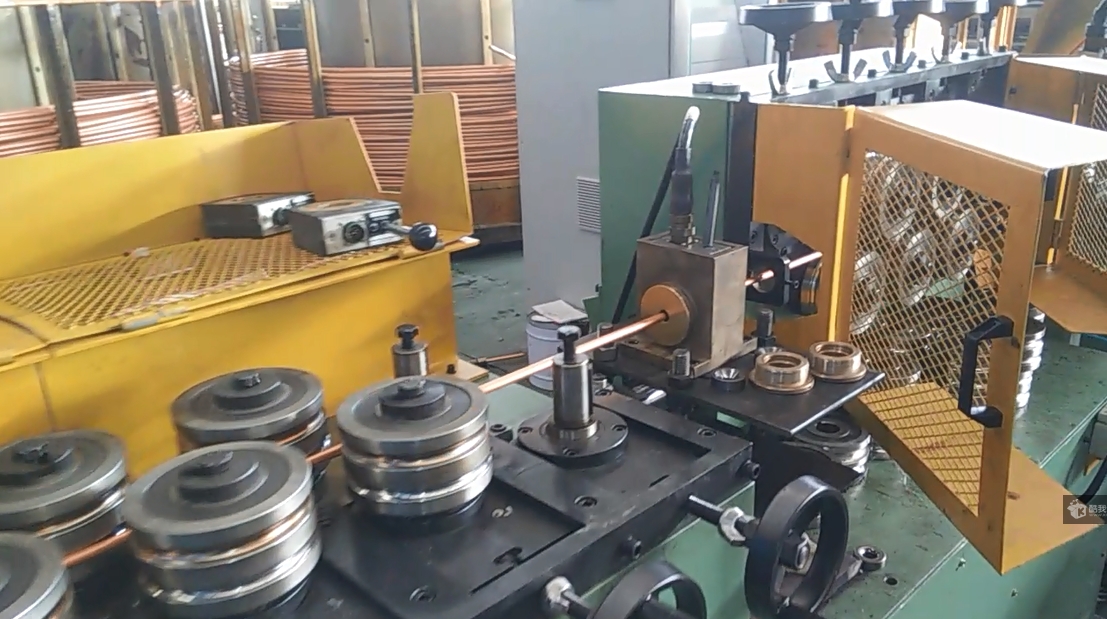

Isakhiwo somatshini

Isithando somlilo esiqhubekayo kwi-intanethi senziwe ngendlela yokukhupha, ibamba kunye nokulungisa inginginya, isithando somlilo esiphakathi, isixokelelwano sokupholisa esijikelezayo kwi-intanethi, indlela yokomisa, indlela yoxinzelelo, indlela yokufumana kunye nenkqubo encedisayo yokulinganisa isantya. isixhobo, kunye nenkqubo engundoqo yolawulo lwekhompyutha. Kwiyunithi ye-annealing eqhubekayo ye-intanethi, i-furnace yokufudumeza i-induction ingundoqo yokusebenza okuqhelekileyo komatshini wonke, kunye nenkqubo yokulawula ngokuzenzekelayo yekhompyutheni ingundoqo yokulawula.