- 03

- Dec

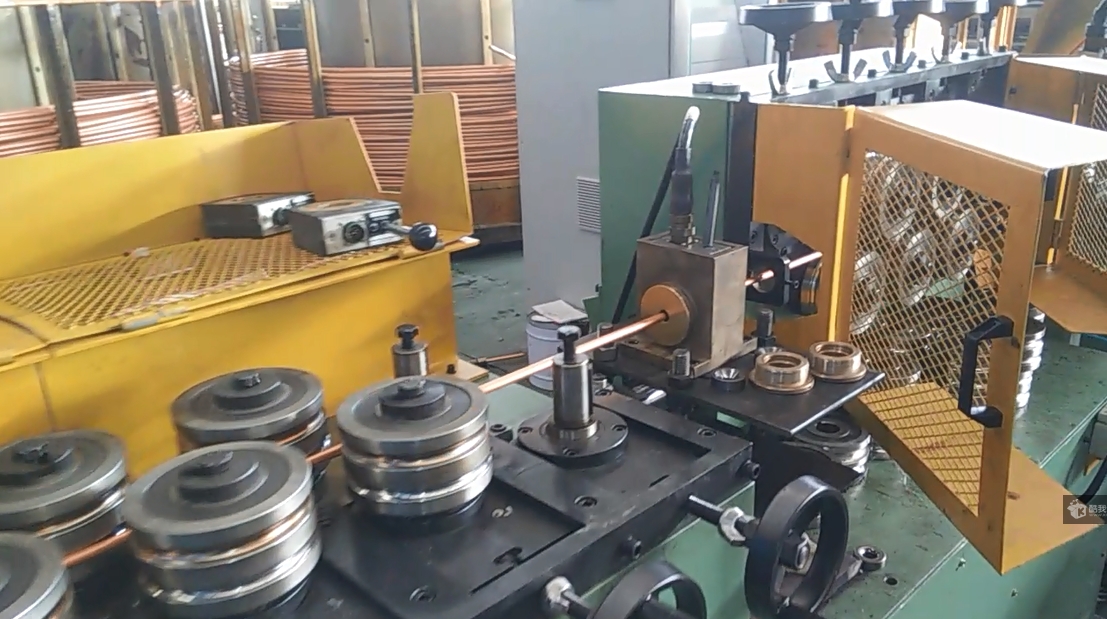

Copper tube induction heating continuous annealing production line

Copper tube induction heating continuous annealing production line

Description of the advanced features of the whole machine:

The copper tube induction heating continuous annealing production line adopts the international advanced series inverter intermediate frequency induction heating power supply. Compared with parallel inverter power supply, energy saving can reach 20%. The power consumption is maintained at 330kwh/T. The series inverter intermediate frequency power supply is very suitable for copper tube induction heating. In the copper tube induction heating, the power factor can reach 0.98. The protection function is complete and the color touch screen display. This series inverter intermediate frequency annealing furnace contains a nitrogen protection system. The annealed copper tube is bright and clean, which is a high-efficiency energy-saving high-tech equipment.

1. The entire annealing process of the material is placed in a protective atmosphere, the surface of the annealed workpiece is bright and non-oxidized, and the surface of the steel is not decarburized.

2. Due to the strong convection circulation of the protective gas in the furnace, the furnace temperature is uniform, so that the temperature difference of the materials in the furnace is within ±5℃; it can effectively ensure that the annealing material at any position is the same in soft and hard, which is convenient for further processing of the material.

3. Adopt double furnace base heating and cooling quasi-continuous operation mode, the furnace structure is scientific and reasonable, the energy saving effect is obvious, the energy consumption per ton of steel is low; the maximum capacity of a single furnace is 30 tons, and the production efficiency is high.

4. The surface of the material treated by this type of furnace is bright, which eliminates the pickling process, cleans the working environment and eliminates acid pollution.

5. The whole set of equipment is controlled by a computer with a high degree of automation, which can effectively ensure product quality and safe operation of the equipment.

Struktura e makinës

The continuous on-line annealing furnace is composed of a discharging mechanism, a clamping and correcting host, a heating intermediate frequency furnace, an on-line circulating cooling system, a drying mechanism, a tensioning mechanism, a receiving mechanism and auxiliary system speed measuring device, and a computer control core system. In the continuous on-line annealing unit, the induction heating furnace is the core of the normal operation of the whole machine, and the computer automatic control system is the control core.