- 23

- Aug

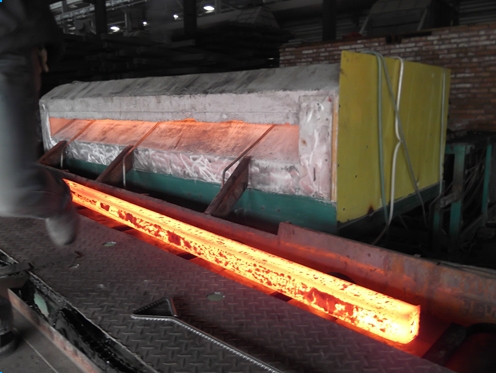

Lò nung cảm ứng phôi đúc liên tục

Continuous casting billet lò sưởi cảm ứng

Steel mills at home and abroad have adopted continuous steel casting technology. The surface temperature of the continuous casting billet after leaving the continuous casting machine is sent to the rolling mill. For rolling, the continuous casting billet has to be cut and stacked, or placed in a uniform temperature furnace to continue heating. For such a continuous casting slab, the average temperature is about 925°C. If supplementary heating is performed on the production line, the continuous casting slab can be heated from 925°C to 1250C, and then rolling can be carried out. Since the surface temperature of the continuous casting slab is low and the temperature of the center part is relatively high, and induction heating is first heated from the surface and the heat is conducted to the center, the continuous casting slab is heated by induction heating for supplementary heating and then continues to roll, which is a good way to save energy. The method makes full use of the waste heat of the blank, and many steel plants have already implemented this process. The heat required for continuous casting billet heating from 925°C to 1250°C is equivalent to 60kWh/t. If the induction heating efficiency is 50%, the unit power consumption is 120kWh/t, which can save energy by 68%. Is the appearance of the continuous casting slab induction heating device,

The number of inductors is determined by the productivity of the continuous casting billet. In order to support the continuous casting slab, water-cooled rollers are arranged between the inductors, and the continuous casting slab is conveyed through each inductor to be heated to the required rolling temperature.

Summary Table of Parameters of Induction Heating Furnace for Continuous Casting Steel Billets

| 钢坯尺寸 | 钢坯长度 | 加热温度 | 生产能力 |

| 60 × 60mm | 3m-4m | 1150 | 25T / H |

| 75 × 75mm | 3m-4m | 1150 | 25T / H |

| 100 × 100mm | 2m | 1150 | 7T / H |

| 120 × 120mm | 1150 | 30T / H | |

| 120 × 120mm | 11.5-12.5m | 1150 | 90T / H |

| 125 × 125mm | 6m | 1150 | 8T / H |

| 125 × 125mm | 2m | 1150 | 7T / H |

| 130 × 130mm | 6m | 1150 | 50T / H |

| 135 × 135mm | 6m | 1150 | 100T / H |

| 150 × 150mm | 11.5-12.5m | 1150 | 70T / H |