- 07

- Feb

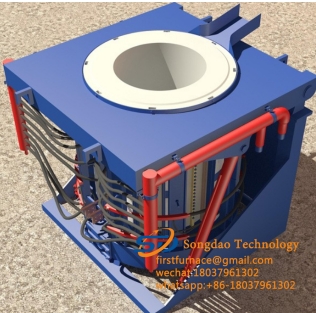

Ukufakwa kunye nokulungiswa kwenkqubo ye-hydraulic ye-induction melting furnace

Ukufakwa kunye nokulungiswa kwenkqubo ye-hydraulic ye-induction melting furnace

Isixhobo sokuqhuba i-hydraulic kufuneka sibe neenzuzo zobukhulu obuncinci, ukuguquguquka kunye nokukhanya, kunye nokulawula kunye nokusebenza kakuhle. Uninzi amaziko anyibilikisayo sebenzisa iinkqubo zokuthambeka kwehydraulic. Uyilo lwesikhululo sempompo yeoli kufuneka siqwalasele ukusetyenziswa okuthembekileyo kunye nokugcinwa okufanelekileyo. Kukho amacandelo okunyibilika aneziko zokunyibilikisa ezininzi zokungeniswa. Iinkqubo ze-hydraulic zesithando somlilo ngasinye kufuneka zikwazi ukuboleka omnye komnye ukunciphisa ixesha lokuvalwa okunyanzeliswayo ngenxa yokugcinwa kwenkqubo ye-hydraulic.

Isikhululo sokupompoza i-fuel sifakwe ngokubanzi kwisiseko esinobude obuthile, obulungele ukukhupha ioli kwi-tank ye-fuel ngexesha lokugcinwa, kwaye ngexesha elifanayo, lilungele ukuveliswa okukhuselekileyo. Nokuba kuthe kwenzeka ingozi enkulu yokuvuza kweziko, itanki yamafutha inokukhuselwa kwintsimbi enyibilikisiweyo. Xa ufaka imibhobho yeoli, kufuneka kwakhona siqhubeke ukusuka kwezona meko zimbi kakhulu, sikuphephe ukudibana nolwelo lwentsimbi enobushushu obuphezulu nangaliphi na ixesha ukuthintela ukwanda kwengozi.

Ukuphelisa ukuvuza kwe-oyile kwi-hydraulic system ngumsebenzi onzima kakhulu. Oku kuqala ngokuphucula umgangatho wofakelo. Amalungu ombhobho we-oyile angadingeki ukuba adityaniswe kufuneka adityaniswe ngokufanelekileyo nge-welding. I-weld kufuneka ixinene kwaye ingavuzi. Emva kwe-welding, coca udonga lwangaphakathi ngaphandle kokushiya i-welding slag kunye nesikali se-oxide. Imibhobho ye-oyile edityanisiweyo enemisonto edityanisiweyo kufuneka ivalwe kwaye ingavuzi kwisakhiwo. Xa ufaka, sebenzisa amanyathelo ancedisayo ahambelanayo, njengokongeza ipeyinti yokuchasana nokuvuza, ukunciphisa ukuvuza kweoli ngexesha lokusebenza.

Emva kokuba kufakwe inkqubo ye-hydraulic, uvavanyo loxinzelelo lwenkqubo yonke kufuneka lwenziwe. Indlela yokudlula kwi-1.5 amaxesha oxinzelelo olusebenzayo lweoli, yigcine imizuzu eyi-15, uhlolisise ngokucophelela yonke into edibeneyo, i-welding kunye ne-interface yecandelo ngalinye, ukuba kukho ukuvuza, kufuneka kuthathwe amanyathelo okuphelisa enye nganye.

Emva kokuba umzimba wesithando somlilo, inkqubo yokupholisa amanzi, kunye nenkqubo ye-hydraulic ifakwe, uvavanyo lokuthotywa komzimba wesithando somlilo kufuneka lwenziwe, kunye nokuhlolwa okupheleleyo komgangatho wofakelo lwesithando somlilo, njengokuba inkqubo yokulawula i-hydraulic iyaguquguquka kwaye inokuthenjwa, nokuba isenzo ngasinye. ichanekile; nokuba umzimba wesithando somlilo kunye nesigqubuthelo somlilo siyasebenza ngokwesiqhelo; Xa umzimba wesithando somlilo ugxininiswe kwi-95 °, ingaba ukutshintshwa komda udlala indima yokukhusela, kwaye ulungelelanise uxinzelelo kunye nokuhamba kwenkqubo ye-hydraulic ukuze isebenze kakuhle. Ngelixa uthambisa isithando somlilo, jonga umgangatho wofakelo lwamalungu ashukumayo enkqubo yokupholisa amanzi. Akukho manzi avuzayo okanye athintele ukuthambeka kweziko lomlilo; jonga i-hoses ye-hydraulic kunye nenkqubo yokupholisa amanzi, jonga ukuba ubude bufanelekile xa umzimba wesithando somlilo uthambekele, kwaye wenze imilinganiselo efanelekileyo xa kuyimfuneko. Lungisa; khangela ukuba inkqubo yokukhupha amanzi inokusebenza ngokuqhelekileyo xa umzimba wesithando somlilo uthambekele. Ukuba kukho naziphi na iintsilelo, amanyathelo ahambelanayo kufuneka athathwe.