- 07

- Feb

Ukufakwa nokulungiswa kwamaphutha kwesistimu ye-hydraulic yesithando somlilo esincibilikisa induction

Ukufakwa nokulungiswa kwamaphutha kwesistimu ye-hydraulic yesithando somlilo esincibilikisa induction

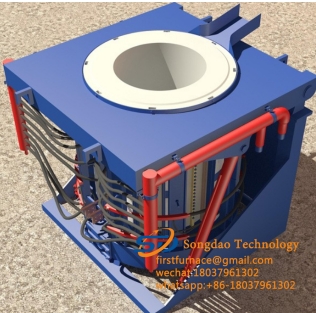

Idivayisi ye-hydraulic drive kufanele ibe nezinzuzo zosayizi omncane, ukuguquguquka nokukhanya, nokulawula nokusebenza okulula. Iningi induction encibilikisa iziko sebenzisa ama-hydraulic tilting systems. Umklamo wesiteshi sephampu kawoyela kufanele ucabangele ukusetshenziswa okuthembekile nokugcinwa okufanele. Kunezigaba zokuncibilika ezineziko zokuncibilika eziningi zokungeniswa. Amasistimu we-hydraulic yesithando somlilo ngasinye kufanele akwazi ukuboleka omunye nomunye ukuze kuncishiswe isikhathi sokuvala ngempoqo ngenxa yokugcinwa kwesistimu ye-hydraulic.

Isiteshi sephampu kaphethiloli ngokuvamile sifakwa esisekelweni esinobude obuthile, esilungele ukukhipha uwoyela ethangini likaphethiloli ngesikhathi sokulungiswa, futhi ngesikhathi esifanayo, sisiza ekukhiqizeni okuphephile. Ngisho noma kwenzeka ingozi enkulu yokuvuza kwesithando somlilo, ithangi likaphethiloli lingavikelwa kunsimbi encibilikisiwe. Lapho sifaka amapayipi kawoyela, kufanele futhi siqhubeke nezimo ezimbi kakhulu, sigweme ukuhlangana noketshezi lwensimbi olunezinga lokushisa eliphezulu noma nini ukuze sivimbele ukwanda kwengozi.

Ukuqeda ukuvuza kukawoyela ohlelweni lwe-hydraulic kuwumsebenzi onzima uma kuqhathaniswa. Lokhu kuqala ngokuthuthukisa ikhwalithi yokufaka. Amalunga epayipi likawoyela okungadingeki ukuba ahlakazwe kufanele axhunywe ngokushisela. I-weld kufanele ibe minyene futhi ingavuzi. Ngemva kokushisela, hlanza udonga lwangaphakathi ngaphandle kokushiya i-welding slag nesikali se-oxide. Amapayipi kawoyela axhumene nentambo kufanele avalwe futhi angavuzi ngesakhiwo. Lapho ufaka, sebenzisa izinyathelo zokusiza ezihambisanayo, njengokwengeza upende ovimbela ukuvuza, ukuze unciphise amathuba okuvuza kwamafutha ngesikhathi sokusebenza.

Ngemuva kokufakwa kwesistimu ye-hydraulic, ukuhlolwa kwengcindezi yalo lonke uhlelo kufanele kwenziwe. Indlela yokudlula izikhathi ezingu-1.5 ukucindezela kokusebenza kwamafutha, yigcine imizuzu engu-15, uhlole ngokucophelela wonke ama-joint, i-welding kanye nokuxhumana kwazo zonke izingxenye, uma kukhona ukuvuza, izinyathelo kufanele zithathwe ukuze kuqedwe ngamunye ngamunye.

Ngemuva kokufakwa kwesithando somlilo, isistimu yokupholisa amanzi, kanye nesistimu ye-hydraulic, ukuhlolwa kokutshekisa umzimba wesithando somlilo kufanele kwenziwe, nokuhlolwa okuphelele kwekhwalithi yokufaka isithando somlilo, njengokuthi uhlelo lokulawula i-hydraulic luyaguquguquka futhi luthembekile, kungakhathaliseki ukuthi isenzo ngasinye. kulungile; noma ngabe umzimba wesithando somlilo kanye nesembozo sesithando somlilo siyasebenza Okujwayelekile; Uma umzimba wesithando somlilo utshekele ku-95 °, noma ngabe inkinobho yomkhawulo idlala indima yokuphepha, futhi ilungisa ukucindezela nokugeleza kwesistimu ye-hydraulic ukuze ikwenze kube sesimweni esihle sokusebenza. Ngenkathi utshekisa isithando somlilo, hlola ikhwalithi yokufaka yamalunga anyakazayo wesistimu yokupholisa amanzi. Akukho manzi avuzayo noma avimbe ukutsheka kwesithando somlilo; hlola amapayipi e-hydraulic kanye nesistimu yokupholisa amanzi, bheka ukuthi ubude bufanelekile yini lapho umzimba wesithando somlilo utshekiswa, futhi wenze izinyathelo ezifanele uma kunesidingo. Lungisa; hlola ukuthi uhlelo lokudonsa amanzi lungasebenza ngokujwayelekile lapho umzimba wesithando somlilo utshekile. Uma kutholakala noma yikuphi ukushiyeka, izinyathelo ezihambisanayo kufanele zithathwe.