- 03

- May

Indlela yokukhetha isithando sokufudumala sokufudumala kwipayipi yensimbi yokufudumeza?

Indlela yokukhetha i ukufudumeza iziko ukufudumeza umbhobho wentsimbi?

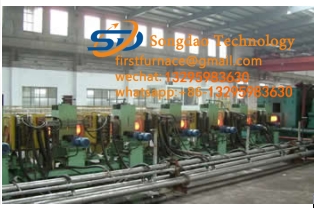

Isithando sokufudumala se-Induction yokufudumeza umbhobho wentsimbi ukwabizwa ngokuba ngumbhobho wentsimbi ophakathi kwamaza omoya wokufudumeza isithando somlilo, oyeyesizukulwana esitsha esiphuhlisiwe senkqubo yokufudumeza ephezulu yokusebenza. I-induction yokufudumeza iziko lokufudumeza umbhobho wensimbi iyinoveli kuyilo, ingqiqo kwisakhiwo, kwaye ithatha ulawulo oluhlakaniphile lwe-PLC, olunokuqonda konke ukusebenza okuzenzekelayo kokufudumeza umbhobho wentsimbi, kunye nesantya sokufudumeza ngokukhawuleza, ukusebenza kokufudumala okuzinzileyo, ukugcina ukusetyenziswa kwamandla okufudumeza, kunye nokulungileyo. isiphumo sokhuseleko lokusingqongileyo.

1. Isithando sokufudumala sokufudumala kwesithando sokufudumala kombhobho wensimbi silawulwa yi-thyristor medium frequency induction heat power supply, enokusetyenziswa kwamandla aphantsi, ukugcinwa kwamandla kunye nokukhuselwa kwendalo, kunye nokusebenza kakuhle kwemveliso. Emva kokulungelelaniswa kwenkqubo kunye nokutshintsha komthwalo, ukutsibela okuzenzekelayo kwinqanaba lokuguqulwa kwe-resonant frequency yomthwalo yi-50KHZ.

2. Uyilo lokuhanjiswa kwesithando sokufudumala sokufudumala kwipayipi yensimbi yamkela i-V-shaped rollers ezicwangciswe ngokungqongqo ukunciphisa ukuphuma kwe-radial.

3. Isithando sokufudumala sokufudumala kwesithando sokufudumala kombhobho wensimbi sinesantya sokufudumeza ngokukhawuleza, i-oxidation engaphantsi komhlaba, kwaye ifunyenwe kwinkqubo yokufudumeza okujikelezayo, kwaye insimbi inobuqhetseba obuhle kwaye akukho ukugoba.

4. I-interface yomshini womntu we-PLC ukulawulwa ngokuzenzekelayo kwesithando sokufudumala sokufudumala kwipayipi yensimbi yokufudumala kunomsebenzi “wokuqala obalulekileyo”.

5. Inkqubo yokulawulwa kwamandla ombane ozenzekelayo wokufudumeza isithando somlilo sokufudumeza umbhobho wentsimbi: Inokusebenza kakuhle kokuguquguquka kwe-anti-voltage, eqinisekisa ukuba uluhlu lokuguquguquka kombane wegridi yi-± 15%, kunye nokuguquguquka kwamandla okuphuma ± 1%, okungachaphazeli. ukuchaneka kokulungiswa kunye nomgangatho wemveliso.

6. Inkqubo yokufudumeza induction yesithando sokufudumala sokufudumala kwipayipi yensimbi ingenziwa ngokwezifiso ukuyila i-inductor ngokweemfuno, ubungakanani bomsebenzi womsebenzi, imilo kunye nobukhulu bomzimba wesithando somlilo, ukushisa komzimba wesithando somlilo kuyalawuleka, ukonga amandla, ukusebenza kakuhle okuphezulu, kunye nesantya esikhawulezayo.

7. Iqonga lokugcina i-furnace yokufudumeza yokufudumeza umbhobho wensimbi idityaniswe ngamatyhubhu angama-square angama-thick-walled, kunye ne-slope ye-13 degrees, kwaye inokugcina izinto ezingaphezu kwe-20.

8. Ixesha langempela lokujongwa kwamandla e-intanethi ye-induction yokufudumeza i-furnaces yokufudumeza umbhobho wensimbi: imisebenzi eyenziwe ngokwezifiso kunye nokukwazi ukwenza ngokwezifiso iteknoloji yokucubungula ngokusebenzisa inkqubo yokusebenzisana nomntu-ikhompyutheni, i-1300 yedatha ngesekhondi, iqonda ngokwenene ixesha langempela lokujonga amandla e-intanethi.

9. Ukulawulwa kwe-PLC yesithando sokufudumala sokufudumala kwipayipi yensimbi yokufudumala ilawulwa yi-interface yomatshini owenziwe ngokwezifiso ngokukodwa, imiyalelo yokusebenza komsebenzisi, i-console ekude kunye ne-touch-screen ye-industrial system yekhompyutheni, kunye ne-digital high-high- ubunzulu beeparamitha ezihlengahlengiswayo, ezikuvumela ukuba ulawule izixhobo eziluncedo ngakumbi. Kukho inkqubo “yokubuyisela iqhosha elilodwa” kunye nemisebenzi emininzi yokutshintsha ulwimi.

10. Inkqubo yokuhambisa i-roller yesithando sokufudumala sokufudumala kwipayipi yensimbi ithatha indlela yokuhambisa ejikelezayo. I-axis ye-roller kunye ne-axis ye-workpiece yenza i-angle ye-18-21 degrees. I-roller phakathi kwemizimba yesithando somlilo yenziwe nge-304 yensimbi engenazibuthe kunye ne-water-cooled, kwaye i-workpiece ishushu ngokulinganayo.

11. Isithando sokufudumala sokufudumala kwesithando sokufudumala kombhobho wensimbi sifudumeza itoni nganye yentsimbi ukuya kwi-1050 ℃, kwaye sisebenzisa i-310-330 degrees yombane.

12. Ukunikezelwa kwamandla kwesithando sokufudumala sokufudumala kwipayipi yensimbi kulungelelaniswa ngokuzenzekelayo, kwaye ukunikezelwa kwamandla kulungelelaniswa ngokuzenzekelayo kunye nokutshintshwa komthwalo, kwaye uluhlu lohlengahlengiso olungenasinyathelo lubanzi.

13. Isithando sokufudumala sokufudumala kwesithando sokufudumala kombhobho wensimbi sizenzekela ngokupheleleyo kunye nolawulo lwamandla aphezulu. Kwimeko nayiphi na imveliso yamandla ehambelanayo, into yamandla inkulu kune-0.95, kwaye akukho sixhobo sembuyekezo samandla esahlukileyo esifunekayo.

14. Amandla okufudumala kwesithando sokufudumala sokufudumala kwipayipi yensimbi ngokuqhelekileyo yi-200KW-6000KW, kwaye imveliso yeyure yi-0.2-16 yeetoni.

15. Inkqubo yokulawula ubushushu beziko lokufudumeza lokufudumeza umbhobho wentsimbi yamkela umlinganiselo weqondo lobushushu le-infrared PLC ubushushu obuvaliweyo-loop oluzenzekelayo inkqubo yokulawula ubushushu.