- 03

- May

Ungakhetha kanjani isithando sokushisa se-induction sokushisa kwamapayipi ensimbi?

Indlela yokukhetha i- isithando sokushisa sangaphakathi ngokufudumeza ipayipi lensimbi?

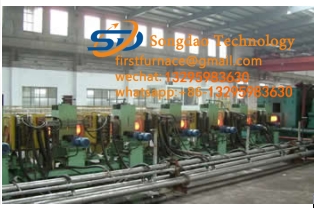

Isithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi sibizwa nangokuthi ipayipi lensimbi i-intermediate frequency induction heat furnace, okungeyesizukulwane esisha esithuthukisiwe sohlelo lokushisa olusebenza kahle kakhulu. Isithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi siyinoveli ekwakhiweni kwayo, sinengqondo ngesakhiwo, futhi samukela isilawuli esihlakaniphile se-PLC, esikwazi ukubona konke ukusebenza okuzenzakalelayo kokushisisa kwepayipi lensimbi, ngesivinini sokushisa esisheshayo, ukusebenza kokushisisa okuzinzile, ukonga ukusetshenziswa kwamandla okushisa, nokuhle. umphumela wokuvikela imvelo.

1. Isithando sokushisa se-induction sokushisa kwamapayipi ensimbi silawulwa yi-thyristor medium frequency induction heat power supply, esebenzisa amandla aphansi, ukonga amandla nokuvikelwa kwemvelo, kanye nokusebenza kahle kokukhiqiza okuphezulu. Ngemuva kokulungiswa kwenqubo nokushintshwa komthwalo, ukugxuma okuzenzakalelayo kwefrikhwensi ukuya ebangeni elilungile lokuguqula imvamisa ye-resonant yomthwalo ngu-50KHZ.

2. Idizayini yokudlulisa yesithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi ithatha amarola amise okwe-V ahlelwe ngokugobile ukuze kuncishiswe ukuphuma kwe-radial.

3. Isithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi sinesivinini sokushisa esisheshayo, i-oxidation encane yangaphezulu, futhi sibonakala ngenqubo yokushisisa okujikelezayo, futhi insimbi inokuqondisa okuhle futhi ayigobi.

4. Isixhumi esibonakalayo somshini womuntu we-PLC ukulawulwa okuzenzakalelayo kwesithando sokushisa sokungeniswa sokushisa kwepayipi lensimbi kunomsebenzi “wokuqala ukhiye owodwa”.

5. Isistimu yokulawula i-voltage ezenzakalelayo yesithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi: Inokusebenza okuhle kokuguquguquka kwe-anti-voltage, iqinisekisa ukuthi uhla lokuguquguquka kwamandla kagesi wegridi lingu-±15%, nokuguquguquka kwamandla okukhiphayo ngu-±1%, okungathinti. ukunemba kokucubungula kanye nekhwalithi yomkhiqizo.

6. Isistimu yokushisa yokungeniswa kwe-induction yokushisa yokushisa kwepayipi yensimbi ingenziwa ngokwezifiso ukuklama i-inductor ngokuvumelana nezidingo, usayizi we-workpiece, ukwakheka kanye nobukhulu bomzimba wesithando somlilo, izinga lokushisa lomzimba womlilo liyalawuleka, ukonga amandla, ukusebenza kahle okuphezulu, nesivinini esisheshayo.

7. Isiteji sokugcina sesithando sokushisa sokungeniswa sokushisa kwamapayipi ensimbi sishiselwa ngamashubhu ayisikwele anezindonga eziwugqinsi, anomthambeka wama-degree angu-13, futhi angagcina izinto ezingaphezu kuka-20.

8. Ukuqapha kwamandla we-inthanethi wangempela wesikhathi sangempela sokushisa kwe-induction ukushisa kwamapayipi ensimbi: imisebenzi eyenziwe ngokwezifiso kanye nekhono lokwenza ngokwezifiso ubuchwepheshe bokucubungula ngokusebenzisa uhlelo lokusebenzisana lomuntu nekhompyutha, idatha ye-1300 ngomzuzwana, qaphela ngempela ukuqapha kwamandla we-inthanethi ngesikhathi sangempela.

9. Ukulawulwa kwe-PLC kwesithando sokushisa esingeniswayo sokushisisa amapayipi ensimbi kulawulwa isixhumi esibonakalayo esenziwe ngokwezifiso ngokukhethekile somshini womuntu, imiyalelo yokusebenza okusebenziseka kalula, ikhonsoli eyirimothi enohlelo lwekhompyutha yezimboni ezithinta isikrini, kanye ne-digital high- ukujula nemingcele adjustable, okukuvumela ukuthi ulawule okokusebenza Ukugunda more. Kukhona uhlelo “lokubuyisela ukhiye owodwa” kanye nemisebenzi eminingi yokushintsha ulimi.

10. Isistimu yokudlulisa i-roller yesithando sokushisa esingeniswayo sokushisisa ipayipi lensimbi ithatha indlela yokudlulisa ejikelezayo. I-axis ye-roller kanye ne-axis ye-workpiece yakha i-engeli ye-18-21 degrees. I-roller phakathi kwemizimba yesithando somlilo yenziwe ngensimbi engagqwali engama-304 engeyona i-magnetic futhi ipholiswe ngamanzi, futhi umsebenzi wokusebenza ushisisa ngokulinganayo.

11. Isithando sokushisa sokungeniswa sokushisa kwepayipi lensimbi sishisisa ithani ngalinye lensimbi libe ngu-1050 ℃, futhi lisebenzisa amadigri angu-310-330 kagesi.

12. Ukunikezwa kwamandla kwesithando sokushisa kwe-induction yokushisa kwepayipi yensimbi kulungiswa ngokuzenzakalelayo, futhi ukunikezwa kwamandla kulungiswa ngokuzenzakalelayo ngokushintsha komthwalo, futhi ububanzi bokulungiswa okungenasinyathelo bubanzi.

13. Isithando sokushisa sokungeniswa sokushisa kwepayipi lensimbi sizenzakalela ngokugcwele ngokulawula amandla aphezulu. Esimeni sanoma yikuphi okukhipha amandla afanayo, isici samandla sikhulu kuno-0.95, futhi akukho divayisi ehlukile yesinxephezelo samandla edingekayo.

14. Amandla okushisa esithandweni sokufudumala se-induction okushisa kwepayipi lensimbi ngokuvamile angu-200KW-6000KW, futhi okukhiphayo ngehora ngamathani angu-0.2-16.

15. Uhlelo lokulawula izinga lokushisa lwesithando sokushisa esingeniswayo sokushisa kwepayipi lensimbi lisebenzisa isilinganiso sokushisa kwe-infrared PLC izinga lokushisa elivaliwe-loop oluzenzakalelayo lokulawula izinga lokushisa.