- 03

- May

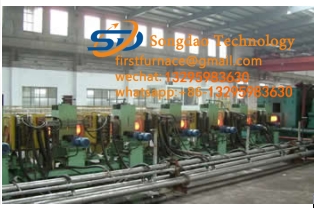

How to choose an induction heating furnace for steel pipe heating?

How to choose an induction heating furnace for steel pipe heating?

Induction heating furnace for steel pipe heating is also called steel pipe intermediate frequency induction heating furnace, which belongs to the newly developed generation of high-performance induction heating system. The induction heating furnace for steel pipe heating is novel in design, reasonable in structure, and adopts PLC intelligent control, which can realize all automatic operation of steel pipe heating, with fast heating speed, stable heating performance, saving heating energy consumption, and good environmental protection effect.

1. The induction heating furnace for steel pipe heating is controlled by thyristor medium frequency induction heating power supply, which has low power consumption, energy saving and environmental protection, and high production efficiency. After process adjustment and load change, automatic frequency hopping to the optimal resonant frequency conversion range of the load is 50KHZ.

2. The transmission design of the induction heating furnace for steel pipe heating adopts V-shaped rollers arranged obliquely to reduce the radial runout.

3. The induction heating furnace for steel pipe heating has fast heating speed, less surface oxidation, and is realized in the process of rotating heating, and the steel has good straightness and no bending.

4. The human-machine interface PLC automatic control of the induction heating furnace for steel pipe heating has the function of “one key start”.

5. Automatic voltage regulation system of induction heating furnace for steel pipe heating: It has good anti-voltage fluctuation performance, ensuring that the grid voltage fluctuation range is ±15%, and the output power fluctuation is ±1%, which does not affect the processing accuracy and product quality.

6. The induction heating system of the induction heating furnace for steel pipe heating can be customized to design the inductor according to the needs, the workpiece size, shape and size of the induction furnace body, the furnace body temperature is controllable, energy saving, high efficiency, and fast speed.

7. The storage platform of the induction heating furnace for steel pipe heating is welded by thick-walled square tubes, with a slope of 13 degrees, and can store more than 20 materials.

8. Real-time online energy monitoring of induction heating furnaces for steel pipe heating: customized functions and the ability to customize the processing technology through the human-computer interaction system, 1300 data per second, truly realize real-time online energy monitoring.

9. The PLC control of the induction heating furnace for steel pipe heating is controlled by a specially customized man-machine interface, highly user-friendly operation instructions, a remote console with a touch-screen industrial computer system, and all-digital high-depth adjustable parameters, allowing you to control the equipment more handy. There is a “one-key restore” system and multiple language switching functions.

10. The roller conveying system of the induction heating furnace for steel pipe heating adopts a rotating conveying mechanism. The axis of the roller and the axis of the workpiece form an angle of 18-21 degrees. The roller between the furnace bodies is made of 304 non-magnetic stainless steel and water-cooled, and the workpiece is heated evenly.

11. The induction heating furnace for steel pipe heating heats each ton of steel to 1050℃, and consumes 310-330 degrees of electricity.

12. The power supply of the induction heating furnace for steel pipe heating is automatically adjusted, and the power supply is automatically adjusted with the load change, and the range of stepless adjustment is wide.

13. The induction heating furnace for steel pipe heating is fully automatic with high power factor control. In the case of any matching power output, the power factor is greater than 0.95, and no separate power compensation device is required.

14. The heating power of the induction heating furnace for steel pipe heating is generally 200KW-6000KW, and the hourly output is 0.2-16 tons.

15. The temperature control system of the induction heating furnace for steel pipe heating adopts infrared temperature measurement PLC temperature closed-loop automatic temperature control system