- 30

- Dec

Indlela yokufaka kunye nokukhangela inkqubo ye-hydraulic ye-furnace yokunyibilika kwe-induction?

Indlela yokufaka kunye nokujonga inkqubo ye-hydraulic ye ukuchithwa kwesithando somlilo?

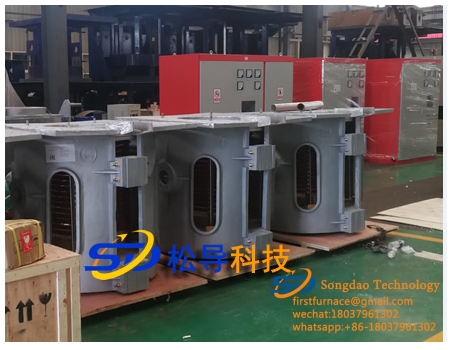

1. Ukufakwa kwenkqubo ye-hydraulic ye-furnace yokuncibilika kwe-induction Ngenxa yokuba ifowuni ye-hydraulic drive ineenzuzo zobukhulu obuncinci, ukuguquguquka kunye nokukhanya, kunye nokulawula okufanelekileyo kunye nokusebenza, i-furnace induction melting ithatha inkqubo ye-hydraulic tilting system. Uyilo lwesikhululo sempompo yeoli kufuneka siqwalasele ukusetyenziswa okuthembekileyo kunye nokugcinwa lula. Kukho ama-furnaces amaninzi e-induction kwicandelo lokunyibilika, kunye neenkqubo ze-hydraulic phakathi kweziko kufuneka zikwazi ukuboleka omnye komnye, ukwenzela ukunciphisa ixesha apho ukuveliswa kuphoqeleka ukuyeka ngenxa yokugcinwa kwenkqubo ye-hydraulic.

2. Isikhululo sempompo yeoli ye-furnace yokuncibilika kwe-induction ifakwe ngokubanzi kwisiseko esinobude obuthile, obulungele ukukhutshwa kweoli kwi-oil tank ngexesha lokugcinwa, kwaye iphinda isebenze kwimveliso ekhuselekileyo. Nokuba kwenzeka ingozi enkulu yokuvuza kweziko, itanki yeoli inokukhuselwa ekuhlaselweni kwentsimbi enyibilikisiweyo. . Xa ufaka imibhobho yeoli, kuyafuneka ukuba uqhubele phambili kwiimeko ezimbi kakhulu, ugweme ukudibana nentsimbi enyibilikisiweyo ephezulu yobushushu nangaliphi na ixesha, kwaye uthintele iingozi ukuba zingandi.

3. Ukuphelisa ukuvuza kweoli kwi-hydraulic system yesithando sokunyibilikisa i-induction ngumsebenzi onzima, oqala ngokuphucula umgangatho wofakelo. Amalungu emibhobho yeoli engadingeki ukuba adityaniswe kufuneka adityaniswe ngokufanelekileyo nge-welding. Iiwelds kufuneka zixinene kwaye kungabikho kuvuza. Emva kwe-welding, udonga lwangaphakathi kufuneka lucocwe, kwaye akukho slag ye-welding kunye ne-oxide scale kufuneka ishiywe. Amalungu ombhobho we-oyile adityaniswe ngemisonto kufuneka atywinwe kwaye angavuzi kwisakhiwo. Xa ufaka, thatha amanyathelo ancedisayo ahambelanayo, njengokongeza ipeyinti yokuchasana nokuvuza, njl., Ukunciphisa ukuvuza kweoli ngexesha lokusebenza.

4. Emva kokufakwa kwenkqubo ye-hydraulic ye-furnace induction melting, uvavanyo loxinzelelo lwenkqubo yonke kufuneka lwenziwe. Indlela yokufaka ioli nge-1.5 amaxesha oxinzelelo lokusebenza kwaye uyigcine imizuzu eyi-15. Jonga ngononophelo umdibaniso ngamnye, i-welding kunye ne-interface yecandelo ngalinye. Ukuba kukho ukuvuza, amanyathelo kufuneka athathwe ukuyiphelisa nganye nganye.

5. Emva kokuba i-intduction melting body body, inkqubo yokupholisa amanzi kunye ne-hydraulic system ifakwe, uvavanyo lwe-induction melting body tilting kufuneka lwenziwe, kwaye umgangatho wofakelo jikelele wesithando kufuneka uhlolwe, njengokuba ingaba inkqubo yokulawula i-hydraulic system. i-furnace yokunyibilikisa i-induction iyaguquguquka kwaye inokwethenjelwa, kwaye isenzo ngasinye Ingaba ichanekile; ingaba ukusebenza komzimba wesithando somlilo kunye nesigqubuthelo somlilo we-induction melting furnace kuyinto eqhelekileyo; xa i-furnace body of the induction melting furnace igxininiswe kwi-95 °, ingaba ukutshintshwa komda womda udlala indima yomshuwalense, kwaye ulungelelanise uxinzelelo kunye nokuhamba kwenkqubo ye-hydraulic ukuze isebenze kakuhle.

6. Xa i-furnace yokuncibilika i-induction i-tilted, jonga umgangatho wofakelo lwezihlanganisi ezihambayo zenkqubo yokupholisa amanzi, ukuze ungavuzi amanzi kunye nokuthintela ukunyanzeliswa komzimba wesithando somlilo; khangela i-hoses ye-hydraulic kunye neenkqubo zokupholisa amanzi, kwaye uqaphele ukuba ubude bufanelekile xa umzimba wesithando somlilo uthambekele. Ukuba kuyimfuneko, yenza uhlengahlengiso olufanelekileyo; khangela ukuba inkqubo yokukhupha amanzi ingasebenza ngokuqhelekileyo xa umzimba wesithando somlilo uthambekele, kwaye uthathe amanyathelo ahambelanayo ukuba kukho ukusilela kufunyenwe.