- 30

- Dec

Ungalufaka kanjani futhi uhlole uhlelo lwe-hydraulic lwesithando somlilo esincibilikisa induction?

Ungalufaka kanjani futhi uhlole uhlelo lwe-hydraulic lwe ukuchithwa kwesithando somlilo?

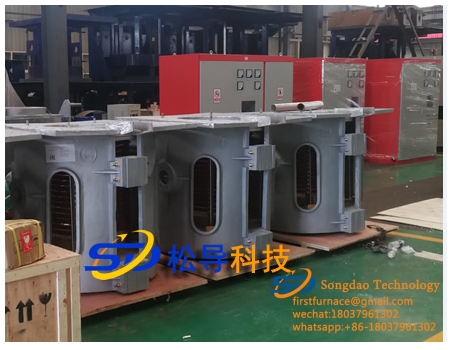

1. Ukufakwa kwesistimu ye-hydraulic yesithando somlilo sokuncibilika kwe-induction Ngenxa yokuthi idivayisi ye-hydraulic drive inezinzuzo zobukhulu obuncane, ukuguquguquka nokulula, nokulawula okulula nokusebenza, isithando somlilo esincibilikayo se-induction samukela uhlelo lokutshekisa i-hydraulic. Ukwakhiwa kwesiteshi sephampu kawoyela kufanele kucabangele ukusetshenziswa okuthembekile nokugcinwa kalula. Kukhona amafurnace amaningi okufakwa ngaphakathi kwesigaba sokuncibilika, futhi izinhlelo ze-hydraulic phakathi kwezithando kufanele zikwazi ukuboleka komunye nomunye, ukuze kuncishiswe isikhathi lapho ukukhiqizwa kuphoqeleka ukuyeka ngenxa yokugcinwa kwesistimu ye-hydraulic.

2. Isiteshi sokupompa uwoyela sesithando somlilo esincibilikisa i-induction ngokuvamile sifakwa esisekelweni esinobude obuthile, esilungele ukukhishwa kwamafutha ethangini likawoyela ngesikhathi sokulungiswa, futhi siphinde sihambisane nokukhiqizwa okuphephile. Ngisho noma kwenzeka ingozi enkulu yokuvuza kwesithando somlilo, ithangi likawoyela lingavikelwa ekuhlaselweni yinsimbi encibilikisiwe. . Lapho ufaka amapayipi kawoyela, kuyadingeka futhi ukuthi uqhubeke usuka ezimeni ezimbi kakhulu, ugweme ukuhlangana nensimbi encibilikisiwe enezinga eliphezulu lokushisa noma kunini, futhi uvimbele izingozi ekukhuleni.

3. Ukuqeda ukuvuza kwamafutha ohlelweni lwe-hydraulic yesithando somlilo sokuncibilika kuwumsebenzi onzima kakhulu, oqala ngokuthuthukisa ikhwalithi yokufaka. Amalunga amapayipi kawoyela angadingi ukuhlakazwa kufanele axhunywe ngokushisela. Ama-welds kufanele aminyene futhi akufanele kube khona ukuvuza. Ngemuva kwe-welding, udonga lwangaphakathi kufanele luhlanzwe, futhi akukho slag welding kanye nesilinganiso se-oxide okufanele sishiywe. Amalunga epayipi likawoyela anoxhumo olunentambo kufanele avalwe futhi angavuzi ngokwesakhiwo. Lapho ufaka, thatha izinyathelo zokusiza ezihambisanayo, njengokwengeza upende ovimbela ukuvuza, njll., ukuze unciphise amathuba okuvuza kwamafutha ngesikhathi sokusebenza.

4. Ngemuva kokufakwa kwesistimu ye-hydraulic yesithando somlilo se-induction, ukuhlolwa kokucindezela kwesistimu yonke kufanele kwenziwe. Indlela yokujova amafutha nge-1.5 izikhathi zokucindezela kokusebenza bese uyigcina imizuzu engu-15. Hlola ngokucophelela ilunga ngalinye, i-welding kanye nokuxhumana kwengxenye ngayinye. Uma kukhona ukuvuza, kufanele kuthathwe izinyathelo zokukuqeda ngamunye ngamunye.

5. Ngemuva kokufakwa kwesithando somlilo esincibilikisa i-induction, isistimu yokupholisa amanzi kanye nesistimu ye-hydraulic, kufanele kwenziwe ukuhlolwa kokutshekisa umzimba kwesithando somlilo esincibilikayo, futhi ikhwalithi yokufakwa kwesithando somlilo kufanele ihlolwe, njengokuthi uhlelo lokulawula i-hydraulic isithando somlilo se-induction siyavumelana nezimo futhi sithembekile, futhi isenzo ngasinye Kungakhathaliseki ukuthi silungile; kungakhathaliseki ukuthi ukusebenza kwesithando somlilo kanye nesembozo sesithando somlilo we-induction melting kuvamile; lapho umzimba wesithando somlilo we-induction melting furnace utshekele ku-95 °, kungakhathaliseki ukuthi umkhawulo wokushintsha umkhawulo udlala indima yomshuwalense, futhi ulungise ukucindezela nokugeleza kwesistimu ye-hydraulic ukuze isebenze kahle.

6. Uma isithando somlilo sokuncibilika se-induction sitshekile, hlola izinga lokufakwa kwezihlanganisi ezihambayo zesistimu yokupholisa amanzi, ukuze ungavuzi amanzi futhi uvimbele ukutshekiswa kwesithando somlilo; hlola amapayipi ezinhlelo zokupholisa amanzi kanye namanzi, bese ubheka ukuthi ubude bufanelekile yini lapho umzimba wesithando somlilo utshekiswa. Uma kunesidingo, yenza izinguquko ezifanele; hlola ukuthi uhlelo lokudonsa amanzi lungasebenza ngokujwayelekile lapho umzimba wesithando somlilo uthambekele, futhi uthathe izinyathelo ezihambisanayo uma kukhona ukusilela okutholakalayo.