- 08

- Sep

Uhlobo oluhlukanisiwe oluyisisekelo sezitini esiphefumula

Uhlobo oluhlukanisiwe oluyisisekelo sezitini esiphefumula

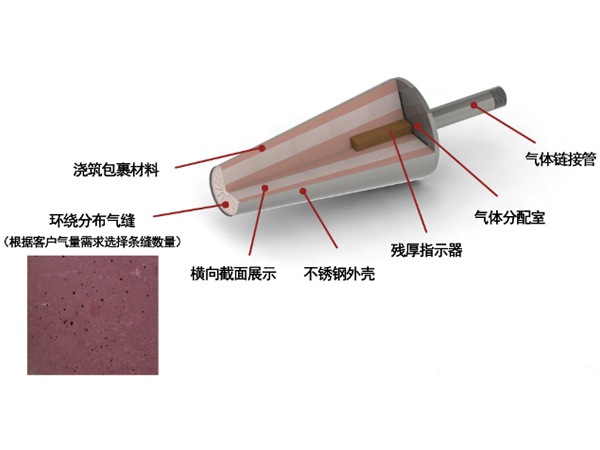

Isigaba: Slit Breathable Brick Core

Izitini ezingena ngaphakathi emoyeni ezihlukanisiwe Izitini ezinomoya ovulekile ezihlukaniswe ngumoya kusetshenziswa izindlela zokwakha izitini ezivumela umoya. Ngokuya ngemibandela yokusetshenziswa esizeni, kufaka phakathi uhlobo lwensimbi olucwengiweyo, inqubo yokucwenga, umthamo we-ladle, izinga lokushisa, ingcindezi yensimbi ye-hydrostatic, njll. isikhathi sokuphila esisetshenziswayo siyanda, futhi ukusebenza kwezokuphepha kuzinzile. Uma kuqhathaniswa nokusebenza kwezitini ezingangena ngaphakathi emoyeni, ukungena kwomoya kanye nempilo yesevisi yezitini ingcono kunaleyo yemikhiqizo ethunyelwe ngaphandle, ehlangabezana nezidingo zezinkomba zokusebenza zokukhiqizwa kwamaladi.

Performance:

1. Ukumelana kweSlag

Ukuze uthuthukise ukumelana kwempahla ye-slag nokumelana nokungena kwensimbi okungamanzi, i-Cr2O3 noma ingxenye ye-chromium corundum ivame ukungezwa kwizitini ezivumeleka emoyeni ezingena ngaphakathi. I-Cr2O3 ne-a-Al2O3 zinesakhiwo esifanayo se-crystal. I-Cr2O3 ayigcini nje ngokuthuthukisa ukumelana kwempahla, kepha futhi inyusa ne-wetting angle phakathi kwento nensimbi encibilikisiwe, futhi ithuthukisa kakhulu ukuvinjelwa kwama-pores esitini esiphefumula ngenxa yokungena kwensimbi encibilikisiwe.

Usebenzisa i-Cr2O3 powder enhle ne-Al2O3 ekushiseni okuphezulu ukwakha isixazululo esiqinile se-aluminium-chromium kanye nesigaba sengilazi esine-chromium esivele ikhona, isigaba samanzi esakhiwe lapho sihlangana ne-slag kwinqubo yokuncibilikisa insimbi encibilikisiwe ine-viscosity ehleliwe, ngaleyo ndlela ukuvimbela i-slag ensimbi encibilikisiwe ekuthinteni i-Corrosion yezitini ephefumula; Ngasikhathi sinye, ingamunca i-iron oxide ne-magnesium oxide ku-slag, bese yakha i-spinel esinyene kusendlalelo esisebenzayo sesitini esingena umoya, esenza ngcono ukumelana kwe-slag kwesitini esingena umoya.

Kodwa-ke, ngemuva kokungeza i-Cr2O3 kulokho okusetshenzisiwe, ngemuva kokudubula noma ukusetshenziswa okushisa okuphezulu, i-Cr3 + ixhunywe ku-Cr6 +, enobuthi futhi ingcolisa imvelo. Ngakho-ke, ngokulondolozwa kwamandla nokuvikelwa kwemvelo, ukusetshenziswa kweCr2O3 kufanele kugwenywe ngangokunokwenzeka, futhi ngokufaka izinto ezingavuthiwe, ukusebenza kokushisa okuphezulu ngaphandle kokungeza i-Cr2O3 kungafinyelela ezingeni lokungeza i-Cr2O3.

2. Thermal ukushaqeka ukumelana

Indlela eyinhloko yokulimala kwezitini ezivumela umoya ukulimala okushisayo. Ngokwanda okuqhubekayo kokushisa kokushaya, kunomehluko omkhulu wokushisa phakathi kokusebenza nokusebenza ngezikhathi ezithile ebusweni bokusebenza kwesitini esingena umoya, esidinga ukuthi okokusebenza kube nokumelana nokushaqeka okuphezulu okushisayo. Isigaba se-spinel sethulwa ku-castable, futhi ukumelana nokushaqeka okushisayo kwesitini esingena emoyeni kuzothuthukiswa.

I-oxide noma i-non-oxide engezwe esitinini esinomoya ongena umoya yakha isigaba sesisombululo esiqinile ngesilinganiso ekushiseni okuphezulu, inyusa amandla okushisa aphezulu esitini, ithuthukise ukungena kwesitini, futhi imelana nokuguguleka kwesitini esinomoya i-slag encibilikisiwe ku-ladle. Ngemuva kokwelashwa kokushisa okuphezulu kwesitini esingena emoyeni, ukusebenza kwaso kuyathuthukiswa ukuhlangabezana nezidingo zokusetshenziswa kwaso

.