- 19

- Sep

Hydraulic transmission principle of ladle sliding nozzle

Hydraulic transmission principle of ladle sliding nozzle

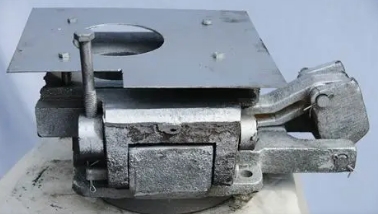

Large and medium-sized ladle generally use hydraulic transmission devices to solve the problem of opening and closing sliding nozzles. Hydraulic transmission is driven by liquid (common oil) as the working medium. Because the liquid has almost incompressible characteristics, when the liquid is filled with a closed container (consisting of oil pumps, pipes, valves, cylinders, etc.), the liquid is pressurized by the oil pump, and it can lose this pressure through pipes, valves, etc. It is transmitted to the oil cylinder very small, causing the oil cylinder to move and realizing hydraulic operation. Reasons for steel leakage between sliding nozzles and preventive measures

(1) The reason for the leakage of the gap between the drain and the lower sliding plate: the sliding plate is not baked after pre-installation; the cement is not evenly coated during installation, resulting in gaps; there are bricks in the cement to make the contact loose.

Preventive measures: The fire mud must be clean during installation, the joints must be evenly seamed, and can only be used after baking and drying.

(2) The reason for the leakage of the upper and lower slide plates: the sliding surface is not flat; the upper and lower slide plates are cracked at the edge of the injection hole; the adjustment operation is not tight or the front and back are uneven.

Preventive measures: pay attention to choosing flat skateboards. Do not use skateboards without steel hoops to prevent cracking at the edge of the injection hole; the adjustment operation should be tight and even before and after.

- The reason for the leakage of the gap between the upper nozzle and the upper sliding plate: the upper sliding plate and the upper sliding plate are not evenly coated with mud; the mass in the fire mud causes the male and female mouths to be insufficiently deep and disconnected; the gap is too large. Preventive measures: the fire mud should be clean, and the joints should be evenly cracked.