- 11

- Apr

How to choose a round steel induction heating quenching and tempering production line?

How to choose a round steel induction heating quenching and tempering production line?

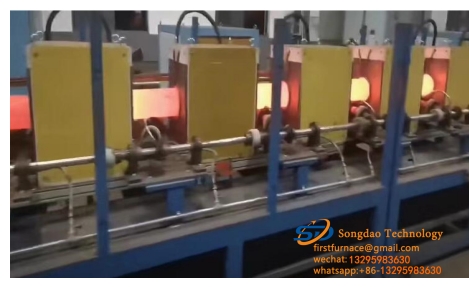

The production line is fully automated, and the round steel induction heating quenching and tempering production line fully realizes the integrated control of microcomputers. During production, only the buttons corresponding to different materials are required to start production. The temperature between each point in each production link can be displayed at the plc display screen. Display and control, the thickness of the round steel quenching layer is large, and the round steel after the round steel induction heating quenching and tempering production line has uniform hardness,

Round steel induction heating quenching and tempering production line The temperature system consists of several parts. Conveying roller table: The axis of the roller table is rotated with the machine, and the round steel is selected at a constant speed, so that the heating is more uniform and the furnace body is separated. The roller table is grouped into a feeding group, a sensor group and a discharging group, which respectively generate gaps between the workpieces. The spray system adopts multi-stage adjustable spray volume to meet the requirements of different hardenability. The main console adopts German Siemens PLC and Taiwan Huayan industrial control system as the core control part, automatic matching and adjustment of mechanical operation parameters, quenching and tempering parameters, power supply, etc., and functions such as display, storage and printing of each parameter.