- 28

- Jul

Method for melting steel and scrap steel in induction melting furnace

- 28

- Juil

- 28

- Juil

Method for melting steel and scrap steel in induction melting furnace

Before the induction furnace is charged, the residue in the furnace should be removed, and the damage of the furnace lining should be checked. The severely damaged parts have become black due to rapid cooling and should be repaired. The grain size of the repairing material should be slightly smaller than that of the knotted material, and the binder used should be slightly more. Large-scale furnaces that are severely damaged can be hoisted into the furnace iron mold to fill in knots.

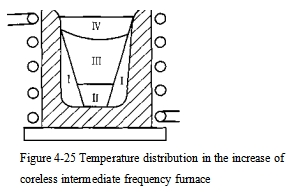

Since the temperature of the induction furnace drops quickly after tapping, it should be charged quickly and should be filled with barrels as much as possible. In order to speed up the melting, the material should be distributed reasonably according to the temperature distribution in the furnace. The temperature distribution in the induction furnace is shown in Figure 4-25. Due to the skin effect of the current, the surrounding surface of the material column (zone I) near the wall of the volute is a high temperature zone.

The bottom and the middle (I, TT zone) have relatively poor heat dissipation, which is a higher temperature zone, and the upper part (IV zone) has less magnetic flux and large heat loss, which is a low temperature zone.

In order to form slag in advance, 1% of the slag material by weight can be added to the bottom of the furnace before charging, lime and fluorite are added to the alkaline furnace, and glass cullet is added to the acid furnace.

At the beginning of melting, because the inductance and capacitance on the line cannot be matched quickly and properly, the current is unstable, so it can only be supplied with low power in a short time. Once the current is stable, it should be switched to full load transmission. During the melting process, the capacitor should be constantly adjusted to keep the electrical equipment with a high power factor. After the charge is completely melted, the molten steel is overheated to a certain extent, and then the input power is reduced according to the smelting requirements.

The proper melting time should be controlled. If the melting time is too short, it will cause difficulties in the selection of voltage and capacitance. If it is too long, it will increase the useless heat loss. Improper cloth or excessive rust in the furnace material will cause “bridging” phenomenon, which should be dealt with in time. “Bridge” prevents the unmelted material at the upper part from falling into the molten steel, stagnating the yuhua, and overheating the bottom of the molten steel can easily damage the furnace lining, and it will also cause the molten steel to absorb a large amount of gas.

Due to electromagnetic stirring, the middle of the molten steel bulges, and the slag often flows to the edge of the crucible and adheres to the furnace wall. Therefore, the slag should be continuously added according to the furnace conditions during the melting process.