- 05

- Dec

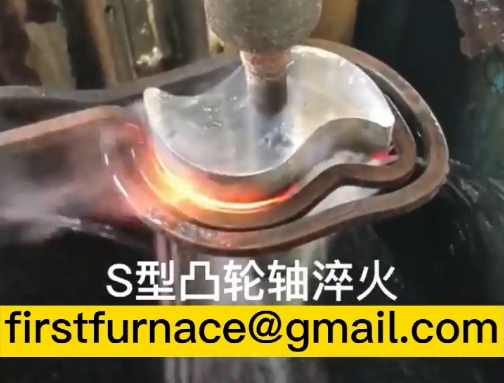

Camshaft Quenching Tshuab

Camshaft Quenching Tshuab

Lub camshaft yog ib feem ntawm lub cav piston. Nws txoj haujlwm yog los tswj qhov qhib thiab kaw ntawm lub valve. Lub hom phiaj ntawm camshaft quenching yog los hloov cov supercooled austenite rau hauv martensite los yog bainite kom tau ib tug martensite los yog bainite qauv, thiab ces temper nws nrog sib txawv kub kom zoo heev txhim kho lub zog, hardness, thiab kuj ntawm cov hlau. Grindability, qaug zog thiab toughness, thiab lwm yam., kom ua tau raws li qhov sib txawv siv cov kev cai ntawm ntau yam khoom siv thiab cov cuab yeej.

Kev ua tau zoo ntawm camshaft hardening tshuab cuab yeej / ib nrab-ncej induction hardening tshuab cuab yeej:

1. Cov cuab yeej siv tshuab no siv lub PC muaj kev tswj hwm digital, nrog rau kev ua tau zoo, kev debugging yooj yim thiab siv, thiab tuaj yeem ua tau raws li qhov xav tau ntawm quenching ntawm complex workpieces mus rau qhov loj tshaj plaws.

2. Cov cuab yeej siv tshuab no tuaj yeem ua tiav quenching txoj kev: nruam scanning quenching, ib txhij quenching, segmented nruam scanning quenching (teev los ntawm qib ntawm segmentation, tsis tas yuav mus txawv tebchaws, tib yam hauv qab no), segmented simultaneous quenching.

3. Hom workpieces (nyob rau hauv ntau qhov sib thooj qhov ntev) muaj feem xyuam rau cov cuab yeej tshuab no: shafts: ntau yam shafts, stepped shafts, gear shafts, camshafts, semi-shafts, txheej voj voog thiab kawg ntsej muag ntawm disc-puab qhov chaw, thiab lwm yam.

4. Cov kev tswj hluav taws xob ntawm cov cuab yeej siv tshuab no khaws cov quenching cua sov thiab dej txias tswj interfaces. Cov txheej txheem quenching thiab cov txheej txheem txias tuaj yeem tswj tau raws li cov txheej txheem yuav tsum tau ua.

5. Tsawg tus nqi khiav haujlwm. Tsav lub cev muaj zog rau kev sib hloov ntawm cov khoom siv tsuas yog xav tau 250W, thiab lub zog siv ntawm tag nrho lub tshuab yog tsawg dua ib feem tsib ntawm cov cuab yeej siv tshuab.

6. Nws txais yuav profile qauv lub cev, tus nqi qis, lub teeb yuag, kev lag luam thiab siv tau.

7. Yooj yim rau siv thiab khaws cia, tus nqi qis tsis ua haujlwm thiab tsis muaj qhov to.

8. High degree ntawm automation thiab siab ntau lawm efficiency.

9. Cov kev taw qhia kev tsheb nqaj hlau txais cov kab bearings nrog siab precision, tsis tshua muaj kev sib txhuam thiab lub neej ntev.

10. Cov cuab yeej counterweight sib npaug qhov hnyav los ntawm sprockets thiab chains.