- 09

- Oct

Txhim kho kev taw qhia ntawm induction cua sov qhov cub Annealing rauv

Txhim kho kev taw qhia ntawm induction cua sov qhov cub Annealing rauv

Nrog rau kev nthuav dav ntawm induction cua sov zog muab cov cuab yeej technology thiab cov kev vam meej ntawm induction rauv manufacturing technology, induction cua sov qhov cub yuav tsum tau txhim kho kom lawv ib tug tshiab hom kev kho cua sov rauv uas hloov kuj kub qhov cub furnaces thiab tswb furnaces. Cov kev txhim kho tshwj xeeb suav nrog cov hauv qab no.

(1) Hloov thyristor nruab nrab zaus fais fab mov rau kev lag luam zaus fais fab mov. Vim yog siv cov transformers thiab ib tug loj tus naj npawb ntawm balancing capacitors, cov hluav taws xob efficiency ntawm industrial zaus fais fab mov yog ho txo. Tam sim no, lub zog loj thyristor fais fab mov tuaj yeem hloov pauv lub zog zaus fais fab mov rau kev kho cua sov thiab diathermy cua sov. Cov khoom siv hluav taws xob muaj hluav taws xob ntau dua li cov khoom siv hluav taws xob ntau zaus, thiab cov khoom siv nyob hauv thaj chaw me me, kev nqis peev tsawg, thiab kev ua haujlwm ruaj khov. Qhov zaus ntawm qhov nruab nrab zaus fais fab mov tsis yooj yim rau siab dhau, thiab 500 ~ 1000Hz yog qhov tsim nyog dua.

(2) Kev txhim kho cov khoom siv rau lub tshuab ua kom sov lub plhaub thiab lub qhov cub lub cev yuav tsum tau ua los ntawm cov khoom tsis sib nqus xws li aluminium alloy. Sab hauv hauv ob sab phlu ntawm lub inductor tuaj yeem siv cov khoom siv hluav taws xob prefabricated es tsis txhob siv cov ntaub ntawv fiber ntau. Magnets yuav tsum tau teem ib ncig ntawm lub induction kauj los txhim kho hluav taws xob efficiency.

(3) Kev txhim kho rauv hom: Hloov lub qhov cub hom rauv rau hauv lub tswb nrov rau kev ua haujlwm, tshem tawm cov cua kub tsis kam ntawm lub tswb-hom rauv, hloov mus rau induction kauj, siv cov cua sov induction, thiab tshem tawm.

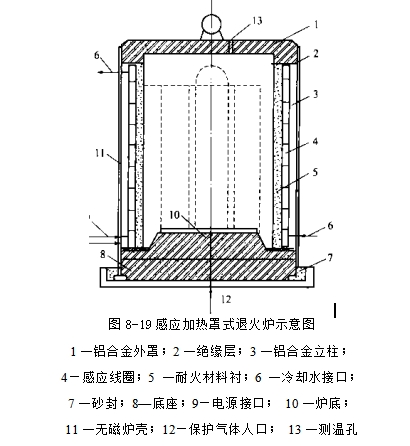

Lub tshav kub-resistant steel liner ntawm lub tswb rauv yog lined nrog cov ntaub ntawv refractory. Cov ncej txhawb nqa ntawm induction coil txais cov qauv ua ke ntawm insulating phaj thiab aluminium alloy kem. Lub hwj chim mov interface thiab cov dej txias inlet thiab qhov hluav taws xob interfaces yog ntsia rau hauv qhov tsim nyog ntawm lub cub tawg plhaub. Ib qho kev sib txuas ruaj khov lossis kev sib txuas yog siv hauv lub plhaub ntawm lub cub tawg. Ib qho dej-txias nruab nrab zaus cable yog siv sab nraum lub plhaub ntawm lub tshuab hluav taws xob los txuas rau lub zog hluav taws xob interface, thiab lub siab hose rau dej yog txuas nrog cov kav dej txias. Lub qhov cub hauv ob sab phlu ua los ntawm cov khoom siv refractory yog siv rau kev sib cais ntawm induction kauj thiab cov hlau. Daim duab kos duab ntawm lwm qhov chaw ntawm lub cub tawg yog qhia hauv daim duab 8-19. Shielding gas tuaj yeem muab tso rau hauv lub qhov cub kom txo oxidation ntawm cov hlau annealed. Qhov cua sov ntawm lub cub tawg yog qhov zoo dua 800 ° C, thiab qhov ntsuas kub yog muab rau hauv nruab nrab ntawm lub qhov cub npog, thiab cov thermocouple tuaj yeem siv los ntsuas thiab tswj qhov kub ntawm lub cub tawg.

Lub tshav kub-resistant steel liner ntawm lub tswb rauv yog lined nrog cov ntaub ntawv refractory. Cov ncej txhawb nqa ntawm induction coil txais cov qauv ua ke ntawm insulating phaj thiab aluminium alloy kem. Lub hwj chim mov interface thiab cov dej txias inlet thiab qhov hluav taws xob interfaces yog ntsia rau hauv qhov tsim nyog ntawm lub cub tawg plhaub. Ib qho kev sib txuas ruaj khov lossis kev sib txuas yog siv hauv lub plhaub ntawm lub cub tawg. Ib qho dej-txias nruab nrab zaus cable yog siv sab nraum lub plhaub ntawm lub tshuab hluav taws xob los txuas rau lub zog hluav taws xob interface, thiab lub siab hose rau dej yog txuas nrog cov kav dej txias. Lub qhov cub hauv ob sab phlu ua los ntawm cov khoom siv refractory yog siv rau kev sib cais ntawm induction kauj thiab cov hlau. Daim duab kos duab ntawm lwm qhov chaw ntawm lub cub tawg yog qhia hauv daim duab 8-19. Shielding gas tuaj yeem muab tso rau hauv lub qhov cub kom txo oxidation ntawm cov hlau annealed. Qhov cua sov ntawm lub cub tawg yog qhov zoo dua 800 ° C, thiab qhov ntsuas kub yog muab rau hauv nruab nrab ntawm lub qhov cub npog, thiab cov thermocouple tuaj yeem siv los ntsuas thiab tswj qhov kub ntawm lub cub tawg.