- 09

- Oct

Isikhokelo soPhuculo lweSithando sokuFundisa soMngxuma wokuNgenisa

Isikhokelo soPhuculo lweSithando sokuFundisa soMngxuma wokuNgenisa

Ngophuhliso lwe amandla okutshisa itekhnoloji yokubonelela kunye nenkqubela phambili yeteknoloji yokuvelisa i-furnace induction, i-induction yokufudumeza iziko kufuneka iphuculwe ukuze ibenze uhlobo olutsha lwesithando somlilo esithatha indawo yokumelana nokufudumeza iziko kunye neentsimbi zentsimbi. Uphuculo oluthile lubandakanya le miba ilandelayo.

(1) Ukutshintsha i-thyristor intermediate frequency power supply yonikezelo lwamandla ombane kushishino. Ngenxa yokusetyenziswa kwee-transformers kunye nenani elikhulu le-bancing capacitors, ukusebenza kombane kwi-industrial frequency power supply kunciphisa kakhulu. Okwangoku, amandla aphezulu e-thyristor anikezela amandla ombane anokuthi atshintshe ngokupheleleyo unikezelo lwamandla ombane wokunyanga ubushushu kunye nokufudumeza kwe-diathermy. Ubonelelo lwamandla lunokusebenza okuphezulu kombane kunombane ophindaphindwayo, kwaye izixhobo zithatha indawo encinci, utyalo-mali oluncinci, kunye nokusebenza okuzinzileyo. Ukuphindaphinda konikezelo lwamandla aphakathi akulula ukuba kuphakame kakhulu, kwaye i-500 ~ 1000Hz ifanelekile ngakumbi.

(2) Ukuphucula izixhobo zesithando somlilo Iqokobhe lesithando somlilo kunye nesibiyeli somzimba wesithando somlilo kufuneka senziwe ngezinto ezingezizo ezemagneti ezifana ne-aluminium alloy. Umgca wangaphakathi we-inductor unokusebenzisa iimveliso ze-refractory zokukhusela ezifakwe ngaphambili endaweni ye-insulating fiber materials. Iimagnethi kufuneka zicwangciswe malunga nekhoyili yokungenisa ukuphucula ukusebenza kombane.

(3) Ukuphuculwa kohlobo lwesithando somlilo: Guqula uhlobo lwesithando somngxuma kwisithando sohlobo lwentsimbi ukwenza umsebenzi wokucoca, ukurhoxisa into yokumelana nobushushu bohlobo lwentsimbi, uyitshintshe ibe yi-coil induction, sebenzisa ukufudumeza kwe-induction, kwaye ucime.

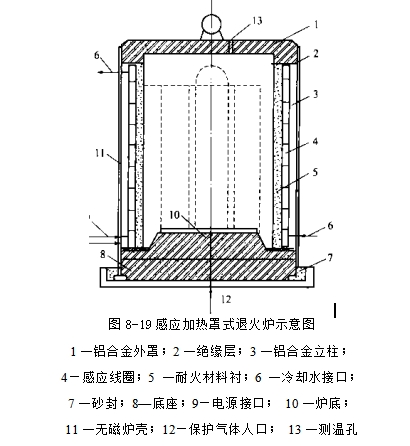

Umgca wensimbi ongenakumelana nokushisa wesithando somlilo wentsimbi ufakwe kwizinto eziphikisayo. Isakhelo esixhasayo se-coil induction sithatha isakhiwo esidibeneyo se-insulating plate kunye nekholomu ye-aluminium alloy. I-interface yonikezelo lwamandla kunye ne-inlet yokupholisa yamanzi kunye ne-outlet interfaces ifakwe kwiindawo ezifanelekileyo ze-shell shell. Ukudibanisa okusisigxina okanye i-interface isetyenziswe ngaphakathi kwegobolondo lesithando somlilo. Ikhebula eliphakathi kwamanzi elipholileyo eliphakathi lisetyenziswa ngaphandle kwegobolondo lesithando somlilo ukuqhagamshela kwi-interface yonikezelo lwamandla, kunye nethumbu loxinzelelo lonikezelo lwamanzi liqhagamshelwe kumbhobho wamanzi okupholisa. Isithando somlilo esenziwe ngezinto ezichasayo sisetyenziselwa ukuzihlukanisa phakathi kwe-coil induction kunye nentsimbi. Umzobo wesakhiwo sezinye iindawo zesithando somlilo uboniswe kuMfanekiso 8-19. Irhasi yokukhusela ingafakwa kwiziko ukunciphisa i-oxidation yentsimbi efakwe kwi-annealed. Ubushushu bokufudumala kwesithando somlilo bukhethwa ngu-800 ° C, kwaye umngxuma wokulinganisa ubushushu unikezelwa phakathi kwesigubungelo sesithando somlilo, kwaye i-thermocouple ingasetyenziselwa ukulinganisa nokulawula ukushisa kwesithando somlilo.

Umgca wensimbi ongenakumelana nokushisa wesithando somlilo wentsimbi ufakwe kwizinto eziphikisayo. Isakhelo esixhasayo se-coil induction sithatha isakhiwo esidibeneyo se-insulating plate kunye nekholomu ye-aluminium alloy. I-interface yonikezelo lwamandla kunye ne-inlet yokupholisa yamanzi kunye ne-outlet interfaces ifakwe kwiindawo ezifanelekileyo ze-shell shell. Ukudibanisa okusisigxina okanye i-interface isetyenziswe ngaphakathi kwegobolondo lesithando somlilo. Ikhebula eliphakathi kwamanzi elipholileyo eliphakathi lisetyenziswa ngaphandle kwegobolondo lesithando somlilo ukuqhagamshela kwi-interface yonikezelo lwamandla, kunye nethumbu loxinzelelo lonikezelo lwamanzi liqhagamshelwe kumbhobho wamanzi okupholisa. Isithando somlilo esenziwe ngezinto ezichasayo sisetyenziselwa ukuzihlukanisa phakathi kwe-coil induction kunye nentsimbi. Umzobo wesakhiwo sezinye iindawo zesithando somlilo uboniswe kuMfanekiso 8-19. Irhasi yokukhusela ingafakwa kwiziko ukunciphisa i-oxidation yentsimbi efakwe kwi-annealed. Ubushushu bokufudumala kwesithando somlilo bukhethwa ngu-800 ° C, kwaye umngxuma wokulinganisa ubushushu unikezelwa phakathi kwesigubungelo sesithando somlilo, kwaye i-thermocouple ingasetyenziselwa ukulinganisa nokulawula ukushisa kwesithando somlilo.