- 09

- Oct

Tilmaamaha Hagaajinta ee Foornada Kuleyliyaha ee Godka Annealing

Tilmaamaha Hagaajinta ee Foornada Kuleyliyaha ee Godka Annealing

Horumar la Awoodda kuleylinta kuleylka tignoolajiyada sahayda iyo horumarka tignoolajiyada wax soo saarka foornada induction, foornooyinka godka kuleylinta induction waa in la wanaajiyaa si looga dhigo nooc cusub oo foornada kulaylka ah oo beddelaya foornooyinka godka kululaynta iska caabinta iyo foornooyinka gambaleelka. Horumarka gaarka ah waxaa ka mid ah dhinacyada soo socda.

(1) Ku beddelka tamarta soo noqnoqda ee thyristor ee soo noqnoqda tamarta soo noqnoqda ee warshadaha. Iyada oo ay sabab u tahay isticmaalka transformers iyo tiro badan oo ah capacitors dheelitirka, waxtarka korantada ee tamarta soo noqnoqda warshadaha ayaa si weyn hoos ugu dhacay. Waqtigan xaadirka ah, sahayda tamarta sare ee thyristor waxay si buuxda u bedeli kartaa tamarta soo noqnoqda tamarta daaweynta kulaylka iyo kuleylka diathermy. Korontadu waxay leedahay waxtarka koronto ee ka sarreeya korontadu inta jeer ee korontadu, qalabkuna wuxuu ku yaal meel yar, maalgashi yar, iyo hawlgal deggan. Inta jeer ee tamarta soo noqnoqda dhexdhexaadka ah ma fududa in ay aad u sarreyso, iyo 500 ~ 1000Hz ayaa ku habboon.

(2) Hagaajinta alaabta jidhka foornada Qolofka foornada iyo xayndaabka jidhka foornada waa in laga sameeyaa walxo aan magnetic ahayn sida aluminium aluminium ah. Dahaarka gudaha ee inductor-ku wuxuu isticmaali karaa alaabada soo celisa dahaarka ee horay loo sii diyaariyay halkii uu ka ilaalin lahaa walxaha fiber-ka. Magnets waa in lagu habeeyaa hareeraha gariiradda induction si loo horumariyo waxtarka korontada.

(3) Hagaajinta nooca foornada: U beddel nooca foornada nooca godka foornada nooca gambaleelka si aad u qabato shaqada soo-saarista, baabi’inta kuleyliyaha iska caabinta foornada nooca gambaleelka, u beddel gariiradda induction, adeegso kuleylinta induction, oo joojiso

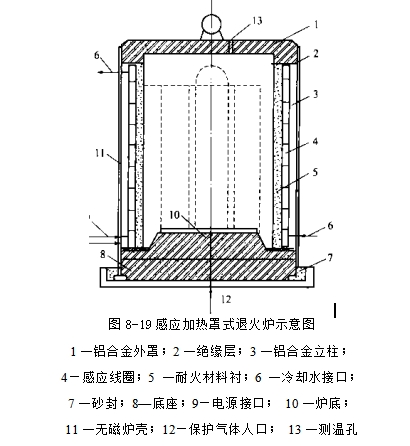

Qalabka birta ah ee kulaylka u adkaysta ee foornada gambaleelka ayaa lagu daboolay walxo dib u celin ah. Qaabka taageerada ee gariiradda induction wuxuu qaataa qaab dhismeedka isku dhafan ee saxanka dahaarka iyo tiirka aluminium aluminium. Isku xirka korantada iyo qaboojinta biyaha gelitaanka iyo meelaha ka baxa ayaa lagu rakibay qaybaha ku habboon qolofka foornada. Isku-xidhka go’an ama is-dhexgalka ayaa lagu isticmaalaa gudaha qolofka foornada. Fiilada dhexdhexaadka ah ee dhexdhexaadka ah ee biyaha qaboojiyey ayaa loo isticmaalaa meel ka baxsan qolofka foornada si loogu xiro interface-ka korontada, iyo tuubada cadaadiska ee sahayda biyaha ayaa ku xiran tuubada biyaha qaboojinta. Dahaarka foornada oo ka samaysan walxo dib u celin ah ayaa loo isticmaalaa go’doomin inta u dhaxaysa gariiradda induction iyo birta. Jaantuska qaab dhismeedka qaybaha kale ee foornada ayaa lagu muujiyay sawirka 8-19. Gaaska gaashaanka ayaa lagu quudin karaa foornada si loo dhimo oksaydheynta birta la shiday. Heerkulka foornada ayaa la doorbidayaa 800 ° C, iyo godka cabbiraadda heerkulka ayaa la bixiyaa bartamaha daboolka foornada, iyo thermocouple ayaa loo isticmaali karaa si loo cabbiro loona xakameeyo heerkulka foornada.

Qalabka birta ah ee kulaylka u adkaysta ee foornada gambaleelka ayaa lagu daboolay walxo dib u celin ah. Qaabka taageerada ee gariiradda induction wuxuu qaataa qaab dhismeedka isku dhafan ee saxanka dahaarka iyo tiirka aluminium aluminium. Isku xirka korantada iyo qaboojinta biyaha gelitaanka iyo meelaha ka baxa ayaa lagu rakibay qaybaha ku habboon qolofka foornada. Isku-xidhka go’an ama is-dhexgalka ayaa lagu isticmaalaa gudaha qolofka foornada. Fiilada dhexdhexaadka ah ee dhexdhexaadka ah ee biyaha qaboojiyey ayaa loo isticmaalaa meel ka baxsan qolofka foornada si loogu xiro interface-ka korontada, iyo tuubada cadaadiska ee sahayda biyaha ayaa ku xiran tuubada biyaha qaboojinta. Dahaarka foornada oo ka samaysan walxo dib u celin ah ayaa loo isticmaalaa go’doomin inta u dhaxaysa gariiradda induction iyo birta. Jaantuska qaab dhismeedka qaybaha kale ee foornada ayaa lagu muujiyay sawirka 8-19. Gaaska gaashaanka ayaa lagu quudin karaa foornada si loo dhimo oksaydheynta birta la shiday. Heerkulka foornada ayaa la doorbidayaa 800 ° C, iyo godka cabbiraadda heerkulka ayaa la bixiyaa bartamaha daboolka foornada, iyo thermocouple ayaa loo isticmaali karaa si loo cabbiro loona xakameeyo heerkulka foornada.