- 22

- Oct

Tungku leleh aluminium frekuensi medium 200KG

Tungku leleh aluminium frekuensi medium 200KG

First, 200KG medium frequency melting aluminum furnace technical specifications and requirements:

1) , smelting material: waste aluminum material, the primary capacity is less than 10-200 kg.

2), peleburan: suhu leleh 1300 derajat, wektu leleh 50-60 menit.

3), 坩 埚: kobongan silikon karbida (ketebalan tembok dhuwur njaba 300mm diameter njaba njaba 220mm) urip layanan 70-80 kaping.

Second, 200KG medium frequency melting aluminum furnace technology solutions and equipment selection

According to the technical requirements of the purchaser, the 200KG medium frequency melting aluminum furnace TXZ-160KW can be selected . The process is as follows:

Bahan logam kasebut dilebokake kanthi manual ing tungku tungku pembuangan.

Sawise logam kasebut cair dadi cairan, awak tungku kontrol listrik lan cairane diwutahake menyang cetakan.

Third , 200KG medium frequency aluminum melting furnace TXZ-160kw quotation: ¥ 70000 yuan (excluding circulating cooling system)

1, the frequency induction heating machine (including power capacitors + box + 200 kg aluminum melting furnace electric overturned)

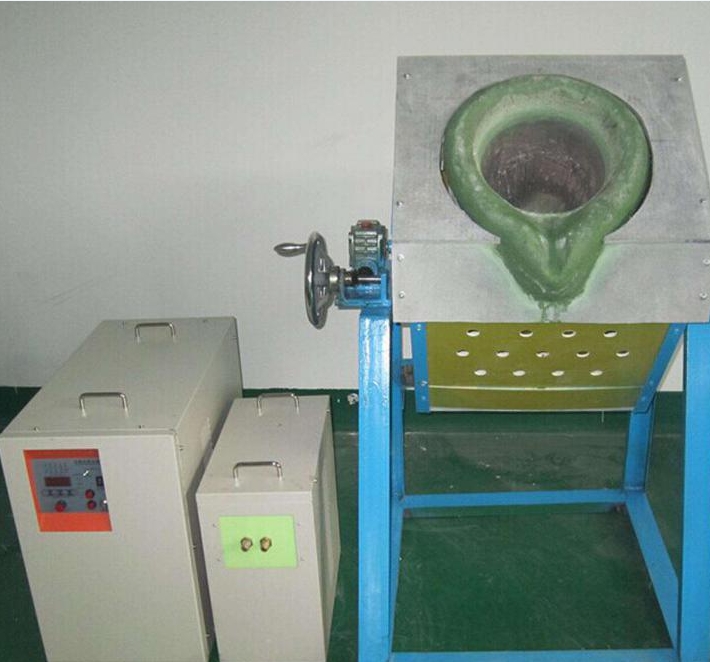

Papat, gambaran referensi gambar: Yen pasokan listrik + kapasitor kompensasi + tungku pembuangan listrik

V. Main technical parameters of T XZ- 1 6 0 kw 200KG medium frequency melting aluminum furnace:

1, daya input maksimum: 160 KW

2, output saiki 40-200 A

3, voltase output: 70-550V,

4, frekuensi osilasi: 1-20KHZ

5, input power : three-phase 380V ± 20% , 50 or 60HZ

6, syarat udara pasokan listrik: 3 × 40 0A

7, volume pasokan listrik (CM): 47 lebar × 95 duwur 85 dawane

8, bobot kekuwatan: 135 KG

9, mbukak tingkat tutugan: 100% 24 jam, kerja terus-terusan

1 0, syarat udara pasokan listrik input: 3 × 150A

11. Syarat kanggo banyu adhem tungku lengkap frekuensi medium: ≥0. 3 Mpa, ≥2 5 / Min

12. Persyaratan banyu pendinginan sumber daya frekuensi medium: ≥ 0.2Mpa ≥ 8 Min

13, dalan banyu listrik: siji menyang banyu, banyu telu

Kaping enem, konfigurasi standar peralatan:

| TX Z – Dhaptar konfigurasi pemanas induksi frekuensi tinggi 160kw | ||||

| Nomer seri | jeneng | unit | Quantity | ujar |

| 1 | Pasokan listrik frekuensi menengah | stasiun | 1 | Standard |

| 2 | Kothak ganti rugi kapasitor | stasiun | 1 | Standard |

| 3 | Aluminum melting 200kgelectric overturningfurnace body | stasiun | 1 | Standard |

| 4 | Kabel sambungan pamisah | Siji | 1 | Standard |

| 5 | Kabel digawe adhem banyu output | pesawat | 1 | Standard |

| 6 | kothak kontrol | Siji | 1 | Standard |

Pitu, aksesoris mesin sing diinstal dhewe (sistem pendinginan sirkulasi):

1. Saklar udara telung tahap 400A Siji

2. Sambungan listrik kabel fleksibel 90 mm2 sawetara meter

3. Menara adhem 30 ton 1;

4. Pompa 3.0kw / endhas 30-50 meter 1 set;

5, pipa banyu mlebu lan stopkontak: pipa banyu kanthi tekanan tinggi diameter njaba njaba 16 mm, diameter njero 12 mm sawetara meter

6, pompa banyu mlebu lan pipa banyu outlet: 1 inci (diameter batin 25 mm) ing pipa bertulang tekanan tinggi sawetara meter

Eight, 200KG intermediate frequency melting furnace using the procedure:

1, sambungan listrik: akses menyang jalur pasokan listrik khusus, saklar udara telung tahap. Banjur sambungake kabel lemah. (Elinga yen listrik listrik telung tahap kudu bisa nggunakake panggunaan peralatan, lan kekandelan kawat kudu digunakake miturut pandhuan)

2, banyu: (gumantung saka wektu kerja lan beban kerja sing terus-terusan) pilih sistem banyu adhem kanggo nggayuh pendinginan sirkulasi banyu.

3, liwat banyu: bukak dalan banyu, lan priksa peralatan saben banyu kanggo ndeleng manawa ana aliran banyu, aliran lan tekanan normal.

4, daya: pisanan mbukak saklar daya kontrol, banjur buka saklar hawa ing mburine mesin, banjur uripake saklar daya ing panel kontrol.

5. Wiwitan: Potensiometer tenaga pemanas kudu disetel nganti minimal sadurunge miwiti tungku pisanan. Sawise wiwitan, suhu kudu disetel karo tenaga sing dibutuhake. Pencet tombol wiwitan kanggo miwiti mesin. Ing wektu iki, indikator pemanas ing panel bakal murup, lan swara cepet saka operasi normal lan lampu bisa digunakake kanthi bebarengan.

6. Pengukuran lan pengukuran suhu: Sajrone proses pemanasan, utamane ditemtokake kanthi cara visual kanggo nemtokake kapan arep mandheg.

7. Pateni: Pateni, piranti kontrol dipateni dhisik, banjur pateni saklar eksternal listrik utama, banjur telat nganti udakara 1 jam sawise tungku mudhun; banjur mateni banyu adhem peralatan, panas ing njero mesin lan kanggo nggampangake koil induksi Panas dipancar.

8. Ing wilayah sing gampang beku ing mangsa adhem, kudu dielingake yen sawise digunakake, hawa sing dikompres kudu digunakake kanggo nyebul banyu metu lan metu saka peralatan kanggo nyegah banyu saka retakan fittings internal lan pipa banyu ing njero peralatan kasebut.

Nine, customer molten aluminum smelting scene pictures: