- 22

- Oct

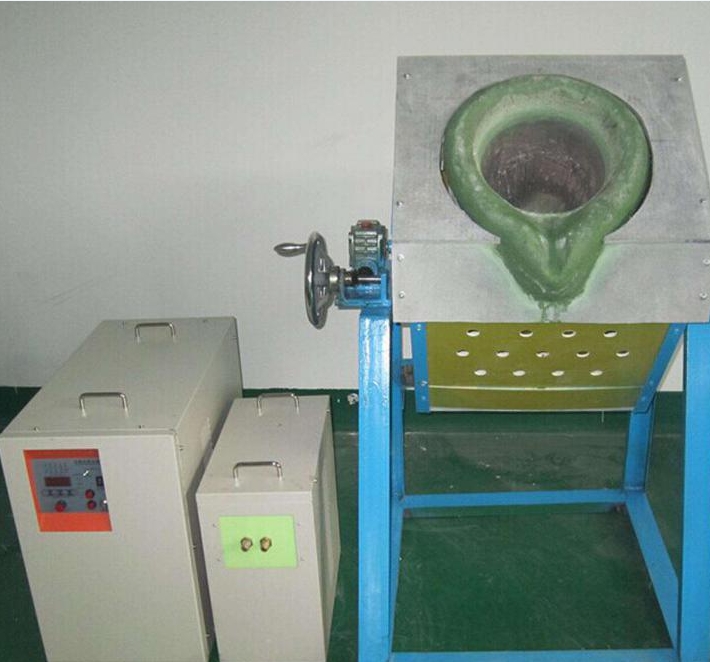

200KG sing’anga yama aluminiyamu yosungunuka pafupipafupi

200KG sing’anga yama aluminiyamu yosungunuka pafupipafupi

First, 200KG medium frequency melting aluminum furnace technical specifications and requirements:

1) , smelting material: waste aluminum material, the primary capacity is less than 10-200 kg.

2), kusungunuka: kutentha kwa madigiri a 1300, nthawi yosungunuka ya mphindi 50-60.

3), 坩 埚: pakachitsulo carbide mbiya (akunja mkulu khoma makulidwe 300mm chapamwamba m’kamwa mwake wakunja awiri 220mm) moyo nthawi 70-80.

Second, 200KG medium frequency melting aluminum furnace technology solutions and equipment selection

According to the technical requirements of the purchaser, the 200KG medium frequency melting aluminum furnace TXZ-160KW can be selected . The process is as follows:

Chitsulocho chimayikidwa pamanja mu ng’anjo yotayira.

Chitsulo chikasungunuka kukhala madzi, thupi lamoto limayang’aniridwa ndi magetsi ndipo madziwo amatsanulira mu nkhungu.

Third , 200KG medium frequency aluminum melting furnace TXZ-160kw quotation: ¥ 70000 yuan (excluding circulating cooling system)

1, the frequency induction heating machine (including power capacitors + box + 200 kg aluminum melting furnace electric overturned)

Chachinayi, malongosoledwe azithunzi: NGATI mphamvu yamagetsi + ikulipirani capacitor + ng’anjo yotayira yamagetsi

V. Main technical parameters of T XZ- 1 6 0 kw 200KG medium frequency melting aluminum furnace:

1, pazipita athandizira mphamvu: 160 KW

2, zotulutsa zapano 40-200 A

3, mphamvu yotulutsa: 70-550V,

4, pafupipafupi oscillation: 1-20KHZ

5, input power : three-phase 380V ± 20% , 50 or 60HZ

6, zolowetsera zamagetsi zofunikira: 3 × 40 0A

7, voliyumu yamagetsi (CM): 47 wide × 95 kutalika 85 kutalika

8, kulemera kwamphamvu: 135 KG

9, kupitiliza kuthamanga: 100% maola 24, ntchito yopitilira

1 0, zofunikira zowonjezera zamagetsi: 3 × 150A

11. Zofunikira pakumwa madzi ozizira ofananira pafupipafupi ng’anjo yathunthu: ≥0. 3 Mpa, ≥2 5 / Min

12. Zomwe madzi amafunikira ozizira pafupipafupi: ≥ 0.2Mpa ≥ 8 Min

13, njira yamagetsi: imodzi m’madzi, madzi atatu

Chisanu ndi chimodzi, zida muyezo kasinthidwe:

| TX Z – 160kw mndandanda wamagetsi owonjezera pafupipafupi | ||||

| Nambala ya siriyo | dzina | Unit | kuchuluka | ndemanga |

| 1 | Mphamvu yamagetsi yapakatikati | siteshoni | 1 | Standard |

| 2 | Bokosi lamalipiro a Capacitor | siteshoni | 1 | Standard |

| 3 | Aluminum melting 200kgelectric overturningfurnace body | siteshoni | 1 | Standard |

| 4 | Gawani chingwe cholumikizira | chimodzi | 1 | Standard |

| 5 | Chingwe choziziritsa madzi | akonzedwa | 1 | Standard |

| 6 | ulamuliro bokosi | chimodzi | 1 | Standard |

Zisanu ndi ziwiri, makina azodzipangira makina (makina ozizira ozizilitsira):

1. Kusintha kwamagawo atatu mpweya 400A One

2. Chingwe cholumikizira mphamvu 90 mm2 mamitala ochepa

3. Yozizira nsanja matani 30 1;

4. Pump 3.0kw / mutu 30-50 mita 1 akonzedwa;

5, zida zolowera ndi kubwereketsa mapaipi amadzi: kuthamanga kwapamwamba kwamadzi chitoliro chakunja m’mimba mwake 16 mm, mkati mwake 12mm mamitala angapo

6, mpope wa madzi olowera ndi chitoliro chamadzi: 1 inchi (mkati mwake 25 mm) mkati mwa waya

Eight, 200KG intermediate frequency melting furnace using the procedure:

1, kulumikiza kwamagetsi: kufikira kwa magetsi opatulira, motsatana, gawo lachitatu la mpweya. Kenako lumikizani waya wapansi. (Dziwani kuti mphamvu yamagawo atatu yamagetsi iyenera kukwanitsa kugwiritsa ntchito zida, ndipo makulidwe a waya ayenera kugwiritsidwa ntchito molingana ndi malangizo)

2, madzi: (kutengera nthawi yogwira ntchito mosalekeza)

3, kudzera m’madzi: tsegulani njira yapa madzi, ndikuyang’ana zida zonse madzi kuti muwone ngati pali kutuluka kwamadzi, kuthamanga ndi kuthamanga kumakhala koyenera.

4, mphamvu: choyamba mutsegule chosinthira mphamvu, kenako tsegulani chosinthira cha mpweya kuseri kwa makina, ndiyeno tsegulani batani lamagetsi pagawo loyang’anira.

5.Kuyambitsa: Mphamvu yotenthetsera potentiometer iyenera kusinthidwa kukhala yocheperako isanayambike ng’anjo yoyamba. Pambuyo poyambira, kutentha kuyenera kusinthidwa ndi mphamvu yofunikira. Dinani batani loyamba kuti muyambe makina. Pakadali pano, chizindikiritso chowotcha pagululo chimawala, ndikumveka kwachangu kwantchito yabwinobwino ndi kuwala kwa ntchito nthawi yomweyo.

6. Kuwona ndi kuyeza kutentha: Pakutentha, zimatsimikizika makamaka ndi njira zowonekera kuti mudziwe nthawi yolekezera kutentha.

7. Kuzimitsa: Kuzimitsa, chida chowongolera chimazimitsa choyamba, kenako zimitsani chojambulira champhamvu chachikulu, kenako chochedwa mpaka pafupifupi ola limodzi kutentha kwa ng’anjo kutatsika; ndiye kuti madzi oziziritsa zida, tenthetsani mkati mwa makina ndikuwongolera coil yothandizira Kutentha kumatulutsidwa.

8. Kudera lomwe kumakhala kosavuta kuzizira m’nyengo yozizira, ziyenera kudziwika kuti nthawi iliyonse mukamagwiritsa ntchito, mpweya wothinikizidwa uyenera kugwiritsidwa ntchito kuwomba madzi mkati ndi kunja kwa zida kuti madzi asalumphe zovekera mkati ndi mapaipi amadzi mkati zida.

Nine, customer molten aluminum smelting scene pictures: