- 16

- Oct

Refractory brick masonry method and requirements for fluidized furnace

Refractory brick masonry method and requirements for fluidized furnace

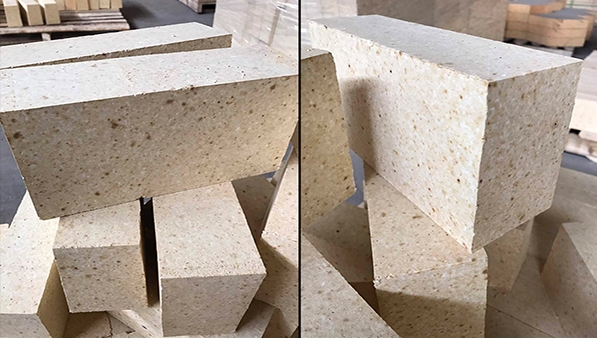

The lining refractories of fluidized bed furnace are mainly composed of refractory bricks and unshaped refractories. The following is the construction method of refractory bricks.

The lining of the fluidized bed furnace is mainly divided into two parts: the wall and the vault.

Henan refractory brick manufacturer, refractory ball manufacturer, lightweight insulation brick, Zhengzhou Huaxin High Temperature Material Co., Ltd.

(1) Refractory brick wall masonry.

Before construction, use theodolite to measure the center line of the furnace, re-measure the elevation of the foundation, and mark the elevation of the first layer of bricks on the furnace shell every 5 meters. Draw a layered line in the vertical direction as a reference for the furnace bottom and furnace wall masonry.

All the brick joints of the brickwork must be filled with adhesive (including the joints between the brickwork and the steel shell and the joints between the brick layers), so that all the brick joints are filled, leaving no gaps and holes. And regularly check whether the position of the masonry is accurate after the masonry is built. For multi-layer brick masonry floors, the total thickness of the brick walls must be checked. The required thickness of the mortar joint should be as much as 2mm (tolerance ±1mm).

Calcium silicate board, thermal insulation brick and thermal insulation refractory brick are provided with a waterproof layer to prevent the absorption of solidified water. The plastering bottom layer can be used to set a waterproof layer.

Expansion joints should be reserved correctly. Paste ceramic fiber felt on one side of the brickwork as an expansion joint to ensure the specified thickness of the expansion joint.

(2) Refractory brick spherical vault masonry.

The top form of boiling furnace is a refractory brick spherical dome. Before refractory construction, the diameter of the furnace steel shell above the supporting dust collector must be checked clockwise. When checking, divide the circumference into 12 equal parts, and check the circumference with a rope. The length of the rope must be equal to the diameter. If there is a defect, the shell manufacturer must be notified to repair the defect.

The mixing of refractory mud should be carried out in strict accordance with the regulations of the product manual.

1) Arch base brick construction: According to the design requirements, ceramic fiber is installed in the expansion joint under the tailstock ring. At the position above the bracket ring and the arch base brick ring, the pressure-resistant silicon fiber board is bonded to the steel shell. To ensure good adhesion, slightly moisten the aluminum silicate fiberboard. Then, the supporting bricks of the arch base bricks are laid on the support. During the masonry process, use a level to check the level of the support ring, and then prefabricate the seal ring of the furnace brick masonry according to the drawings. However, it must be considered to install a 2mm wide sliding joint between the ring and the support ring with greased paper.

Spread mortar on the surface of the supporting bricks, put the arch base bricks on the supporting bricks of the brackets, and fix them with a rubber hammer. The brick is tilted back slightly.

If the construction of the tubular brickwork is not completed at the beginning of the vault construction, a relatively thick adhesive auxiliary material can be applied at the front end to make the arch base bricks slightly inclined. Use a level to check the position of each brick. The inner edge of the brick should be adjusted according to the corresponding inner diameter marked on the drawing. Slight unevenness can be compensated by gluing auxiliary material joints. If there is a large deviation from the original size, the correct fire-resistant concrete can be used or the bricks can be cut to the required size for repair. However, the thickness of the brick should be at least 70% of the original thickness. After the arch base bricks are built, they must be fixed to prevent tilting.

2) Top brick construction: build irregular top brick rings according to the direction of the arch base bricks, and construct in strict accordance with the proportion of each circle of special-shaped bricks marked on the drawings. The average thickness of the mortar joint must be 2mm, and the bonding auxiliary material of the masonry vault brick must be added with a special hardener. When laying bricks in two directions, only after one circle is completed, can the next circle of bricks be laid on the hardened part of the binder. During masonry, the bonding attachment of the upper ring of the brick must be fully hardened. If checking with a tool, the tip of the tool should not be inserted into the joint of the adhesive material.

Only 4 circles of bricks can be built every day, and the unfinished irregular brick circles on the vault must be completed within the same working day.

3) Crown measurement: Check the distance of 12 positions and the diameter of 4 positions outside the circle of each complete crown brick. Check the measurement results according to the values shown in the drawing.

As the dome at the final dome circle is affected by gravity, it may be slightly lower than the value marked on the drawing, so it is necessary to consider that the bricks slightly exceed the elevation position and cannot be less than the marked spacing or diameter.

4) Closure of the vault: After the last round of bricks is paved, use the formwork to pour the refractory concrete upper block in the center of the vault. Fix the template on the dome with fixing lines, and then pour the top stop block from the top. After the concrete is hardened, the formwork is removed, and the brickwork of the vault is built from the upper part.

If it is a dome with a central vent, the construction of the brickwork will continue after the bricks are closed in the last circle.