- 01

- Oct

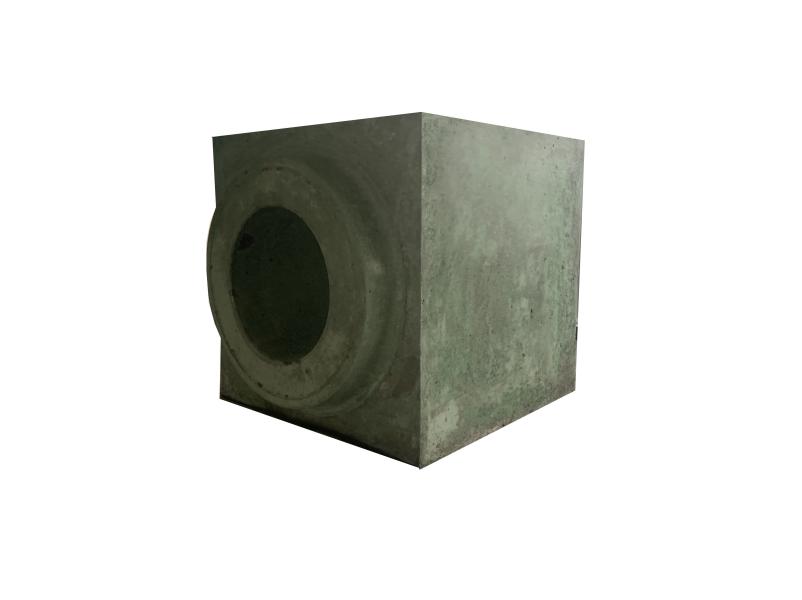

Cov cib ua pa ua pa yog cov khoom siv tseem ceeb hauv qab txheej txheem argon tshuab

Cov cib ua pa ua pa yog cov khoom siv tseem ceeb hauv qab txheej txheem argon tshuab

Cov khoom lag luam yog ua los ntawm cov khoom siv siab-purity, pwm los ntawm kev co casting, thiab ci ntawm qhov kub tsawg. Nws muaj qhov zoo ntawm lub zog thermal siab, thermal poob siab tsis kam, tiv taus corrosion thiab yaig tsis kam, thiab kho kub.

Nqa cov cib ua pa yog lub luag haujlwm tseem ceeb ua cov khoom siv hluav taws xob hauv qab txheej txheem argon tshuab. Nws cov xwm txheej siv yog hnyav heev. Nws yog qhov tshwm sim feem ntau hauv qhov siab ntawm cov cua sov. Thaum ladle nchuav cov hlau thiab argon roj ua rau cov hlau yaj, cov cua nkag mus rau hauv av yog khov heev scoured, sheared thiab abraded los ntawm cov kub kub molten hlau.

Ladle cua-permeable cib tau muab faib ua ob hom raws li txoj hauv kev sib dhos: sab hauv ib puag ncig huab cua-permeable cib thiab sab nrauv cua-permeable cib ua ke. Hais txog kev tshawb fawb ntawm cov cib ua pa, tib neeg feem ntau xyuam xim rau cov teeb meem ntawm cov cib cib ‘tiv thaiv kom yaj poob, tsis tiv taus cov hlau yaj nkag mus, thiab tshuab tshuab los ntawm tus nqi, tab sis kev txiav txim siab me me tau muab rau qhov ua tau zoo ntawm kev txhawb cov cib. Tus sau ntseeg tias txhawm rau txhawm rau txhawm rau txhim kho kev pab lub neej ntawm cov cib ua pa, ua rau nws muaj kev nyab xeeb, thiab ua kom ntseeg tau tias tsis muaj cov hlau xau lossis xau raug xwm txheej tshwm sim, txawm hais tias nws yog cov cib ua pa sab nrauv lossis cov cib ua pa sab hauv, kev tshawb fawb ntawm lub tshuab ua pa lub rooj zaum cib cib yog qhov tseem ceeb ib yam, tshwj xeeb tshaj yog cov cua nkag mus rau sab nrauv muaj qhov xav tau ntau dua rau lub rooj cib.

Hauv cov txheej txheem hlau niaj hnub no, kev siv roj tshuab cov hlau molten pib hauv cov txheej txheem zom thiab xaus rau hauv cov crystallizer. Ua pa ntawm lub rooj zaum cib ua pa rau cov ladle yog lub luag haujlwm tseem ceeb hauv qhov txuas no. Kev ua tau zoo ntawm lub rooj zaum cib ua pa rau cov cib tuaj yeem suav nrog ua cov hauv qab no:

(1) Kub kub ua hauj corrosion

Cov khoom ua kom zoo tau nruj nruj raws li qhov ntsuas kub thiab sijhawm, thiab qhov kub feem ntau nce siab tshaj 1750 ℃. Thaum lub sijhawm ua haujlwm ua kom zoo, qhov tseem ceeb ntawm slag muaj kev cuam tshuam loj rau lub neej ntawm cov khoom siv hluav taws xob. Qhov tseem ceeb ntawm kev ua kom zoo nkauj slag sib txawv hauv thaj tsam ntawm 0.6 txog 0.4. Yog li ntawd, cov khoom siv rov ua dua tshiab yog corroded los ntawm acidic slag thiab alkaline slag uas tuaj yeem nqus tau ntawm qhov kub thiab txias, thiab kev puas tsuaj yog nrawm.

(2) Kub hnyav hnav tsis kam

Ntau txoj kev ua kom zoo dua qub tau txais kev yuam kom sib xyaw, uas yog qhov hnyav heev rau qhov kub kub hnav ntawm cov cib.

(3) Peeling tsis kam

Vim tias nws tsis ua haujlwm ib ntus, qhov kub hloov pauv ntau heev, thiab nws yog qhov yooj yim los tsim cov thermal spalling thiab cov txheej txheem spalling, thiab cov xwm txheej siv yog hnyav heev. Muaj qhov sib txawv loj ntawm qhov ua tau zoo ntawm tam sim no siv cov khoom cua-permeable cib thiab lawv qhov kev cia siab, xws li kev tiv thaiv qhov kub thiab txias tsis kam thiab tsis kam tiv taus, tshwj xeeb tshaj yog qhov tsis kam tiv taus yuav tsum tau txhim kho.