- 01

- Oct

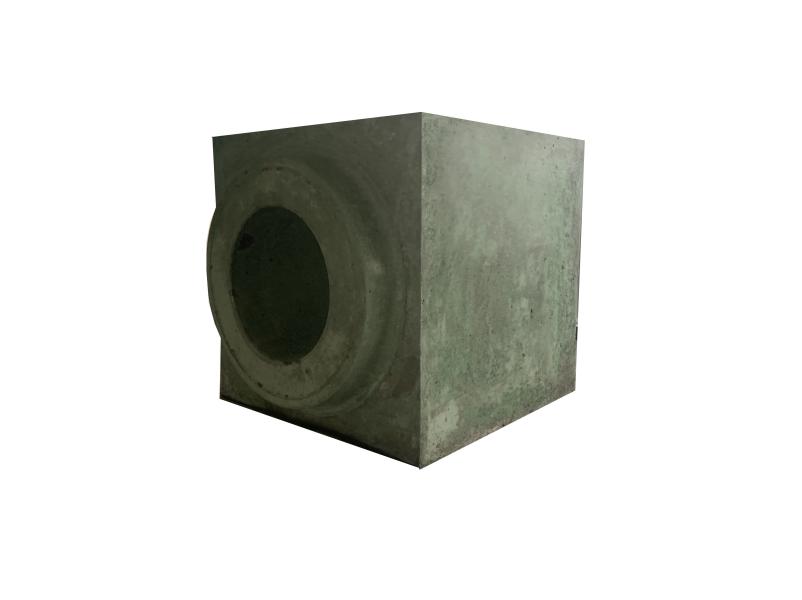

Ladle breathable brick is the key material in the bottom argon blowing process

Ladle breathable brick is the key material in the bottom argon blowing process

The product is made of high-purity raw materials, molded by vibration casting, and baked at low temperature. It has the advantages of high thermal strength, thermal shock resistance, corrosion resistance and erosion resistance, and hot repair.

Ladle breathable brick is a key functional refractory material in the bottom argon blowing process. Its use conditions are very harsh. It is mainly manifested in the high concentration of thermal stress. When ladle pouring steel and argon gas stir the molten steel, the air-permeable brick is strongly scoured, sheared and abraded by the high-temperature molten steel.

Ladle air-permeable bricks are divided into two types according to the assembly method: internal integral air-permeable brick and external air-permeable brick combination. Regarding the research of breathable bricks, people generally pay attention to the problems of core bricks’ resistance to melting loss, resistance to molten steel penetration, and blow-through rate, but relatively little consideration is given to the performance of supporting bricks. The author believes that in order to increase the service life of ventilated bricks, increase its safety factor, and ensure that no steel leakage or steel leakage accidents occur, whether it is an external ventilating brick or an internal ventilating brick, the research on the ventilating brick seat brick is equally important, especially External ventilation bricks have higher requirements for seat bricks.

In the modern metallurgical process, the use of gas blowing molten steel begins in the smelting process and ends in the crystallizer. Breathable brick seat brick for ladle is an important functional element in this link. The main performance of the breathable brick seat brick for ladle can be summarized as the following aspects:

(1) High temperature corrosion resistance

Refined ladle has very strict requirements in terms of temperature and time, and the temperature often reaches above 1750 ℃. During the refining operation, the basicity of slag has a great influence on the life of refractory materials. The basicity of ladle refining slag varies within the range of 0.6 to 0.4. Therefore, the refractory material is corroded by acidic slag and alkaline slag that are highly permeable at high temperatures, and the damage rate is fast.

(2) High temperature wear resistance

Various ladle refining methods have adopted forced mixing, which is very serious for the high temperature wear of the bricks.

(3) Peeling resistance

Because it is intermittent operation, the temperature changes greatly, and it is easy to produce thermal spalling and structural spalling, and the use conditions are very harsh. There is a big gap between the performance of the currently used ladle air-permeable bricks and their expected performance, such as high temperature corrosion resistance and spalling resistance, especially the spalling resistance needs to be improved.