- 20

- Feb

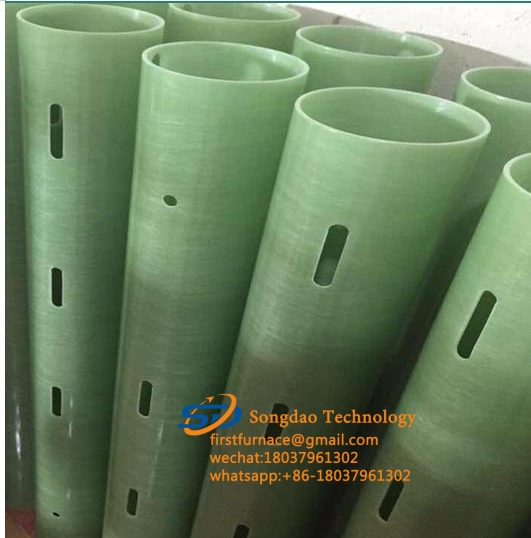

Epoxy iav fiber ntau winding yeeb nkab

Epoxy iav fiber ntau winding yeeb nkab

Epoxy iav fiber ntau winding yeeb nkab yog ua los ntawm uninterrupted fiber ntub winding, tshwj xeeb tshaj yog tsim rau structural qhov chaw ntawm high-voltage hluav taws xob khoom xws li reactors, xob laim ntes, fuses, transformers, on-load kais-changers, transformers, thiab lwm yam. Ua tau raws li IEC cov qauv Yuav Tsum Tau.

Basic parameters of epoxy glass fiber winding pipe:

1: Winding lub kaum sab xis, 45 ~ 65 (lub kaum sab xis winding tuaj yeem hloov kho raws li qhov xav tau sib txawv kom ua tiav cov kev xav tau zoo dua qub);

2: Cov ntsiab lus fiber ntau (qhov hnyav piv), 70 ~ 75%;

3: Ceev, 2.00 g / cm3;

4: Cov dej nqus dej, tsawg dua 0.03%;

5: Axial thermal expansion coefficient, 1.8 E-05 1 / K;

6: iav hloov kub, 110 ~ 120 ℃;

7: Tshuaj tiv thaiv. Mineral roj: zoo heev;

8: Solvent thiab dilute acid: zoo heev;

9: Tensile modulus ntawm elasticity, axial 14000 MPa;

10: Tensile zog; axial 280 MPa; Circumferential 600 MPa;

11: Shear zog: 150 MPa;

12: Flexural zog: 350 MPa nyob rau hauv axial kev taw qhia;

13: Compressive zog: axial 240 MPa;

14: Cov txheeb ze permittivity 2-3.2;

15: Dielectric poob 0.003-0.015;

16: Muaj peev xwm tso tawm ib nrab ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: xob laim cuam tshuam: 110 KV

19: Fais fab zaus poob siab: 50 KV;

20: Kub tiv thaiv qib: B, F, H qib

21: Sab hauv txoj kab uas hla> 5mm; sab nraud txoj kab uas hla <300mm; ntev <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Peb cov khoom tau raug xa tawm mus rau Tebchaws Meskas, Lub Tebchaws Yelemees, Kaus Lim Qab Teb, Nyiv, Europe, Russia thiab lwm lub tebchaws.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!