- 20

- Feb

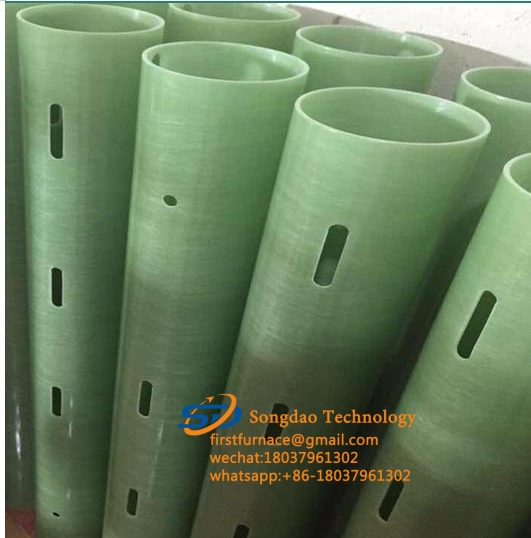

Epoxy galaas fibre dabaysha tuubada

Epoxy galaas fibre dabaysha tuubada

Tuubbooyinka dabaysha ee galaaska Epoxy waxay ka samaysan tahay dabaylo qoyan oo fiber ah oo aan kala go’ lahayn, oo si gaar ah loogu horumariyay qaybaha qaab dhismeedka qalabka korantada-sare ee sida reactors, xidhayaasha hillaaca, fiyuusyada, transformers, beddelayaasha tuubada-load, transformers, iwm. la kulmo heerarka IEC looga baahan yahay.

Basic parameters of epoxy glass fiber winding pipe:

1: xagasha dabaysha, 45 ~ 65 (xagalka dabaysha waxaa lagu hagaajin karaa iyadoo loo eegayo shuruudo kala duwan si loo gaaro shuruudaha waxqabadka farsamada ee wanaagsan);

2: Maaddooyinka fiber-ka (saamiga miisaanka), 70 ~ 75%;

3: Cufnaanta, 2.00 g / cm3;

4: Heerka nuugista biyaha, in ka yar 0.03%;

5: Isku-dhafka fidinta kulaylka axial, 1.8 E-05 1 / K;

6: heerkulka kala guurka galaas, 110~120 ℃;

7: caabbinta kiimikada. Saliidda macdanta: aad u fiican;

8: Aashitada millata iyo milo: aad u fiican;

9: Moodada jilicsan ee jilicsanaanta, axial 14000 MPa;

10: Xoog xajin; axial 280 MPa; wareegyada 600 MPa;

11: Xoog xiirid: 150 MPa;

12: Xoog dabacsanaan: 350 MPa jihada axial;

13: Xoogga cufan: axial 240 MPa;

14: Ogolaanshaha qaraabada 2-3.2;

15: Dhibaatada Dielectric 0.003-0.015;

16: Awoodda sii daynta qayb ahaan ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Saamaynta hillaaca: 110 KV

19: Shoogga soo noqnoqda awoodda: 50 KV;

20: darajada u adkaysiga kulaylka: B, F, H

21: Dhexroorka gudaha>5mm; dhexroorka dibadda <300mm; dhererka <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Alaabadayada waxaa loo dhoofiyay Mareykanka, Jarmalka, Kuuriyada Koonfureed, Japan, Yurub, Ruushka iyo dalal kale.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!