- 20

- Feb

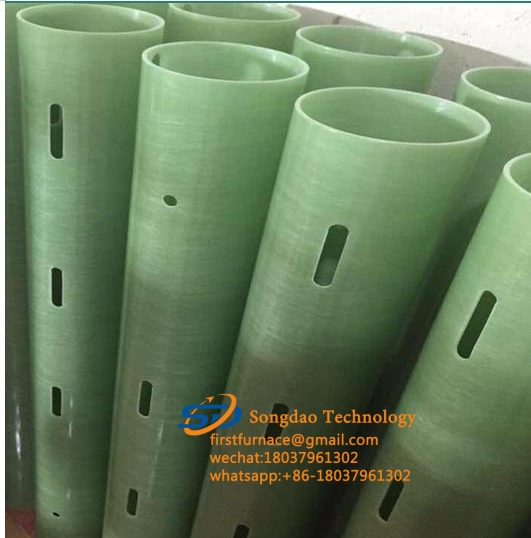

Epoxy glass fiber winding chitoliro

Epoxy glass fiber winding chitoliro

Epoxy galasi CHIKWANGWANI chokhomerera chitoliro amapangidwa ndi zosasokonezedwa CHIKWANGWANI chonyowa mapiringidzo, makamaka opangidwa mbali structural zipangizo mkulu-voteji magetsi monga reactors, zomangira mphezi, fuse, thiransifoma, pa-katundu wapampopi-osintha, thiransifoma, etc. The katundu magawo ntchito kukwaniritsa mfundo za IEC Zofunika.

Basic parameters of epoxy glass fiber winding pipe:

1: Mphepo yokhotakhota, 45 ~ 65 (makona okhotakhota amatha kusinthidwa malinga ndi zofunikira zosiyanasiyana kuti akwaniritse zofunikira zamakina);

2: Zomwe zili mu fiber (chiwerengero cha kulemera), 70 ~ 75%;

3: Kuchulukana, 2.00 g/cm3;

4: Mayamwidwe amadzi, osakwana 0.03%;

5: Axial thermal expansion coefficient, 1.8 E-05 1/K;

6: Galasi kusintha kutentha, 110℃ 120 ℃;

7: Kukana mankhwala. Mafuta amchere: abwino kwambiri;

8: Kusungunula ndi kuchepetsa asidi: zabwino kwambiri;

9: Kuthamanga modulus ya elasticity, axial 14000 MPa;

10: Mphamvu yolimba; axial 280 MPa; zozungulira 600 MPa;

11: Kumeta ubweya wa mphamvu: 150 MPa;

12: Flexural mphamvu: 350 MPa mu axial direction;

13: Mphamvu yopondereza: axial 240 MPa;

14: Chilolezo chachibale 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Kutha kutulutsa pang’ono ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Mphamvu ya mphezi: 110 KV

19: Kugwedeza kwafupipafupi kwamphamvu: 50 KV;

20: Gawo la kukana kutentha: B, F, H kalasi

21: M’mimba mwake> 5mm; m’mimba mwake <300mm; kutalika <2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Zogulitsa zathu zimatumizidwa ku United States, Germany, South Korea, Japan, Europe, Russia ndi mayiko ena.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!