- 20

- Feb

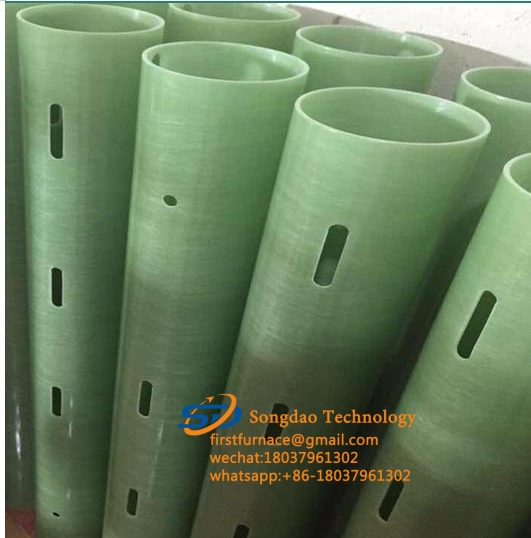

Epoxy glass fiber winding pipe

Epoxy glass fiber winding pipe

Epoxy glass fiber winding pipe is made of uninterrupted fiber wet winding, specially developed for structural parts of high-voltage electrical equipment such as reactors, lightning arresters, fuses, transformers, on-load tap-changers, transformers, etc. The product performance parameters meet IEC standards Require.

Basic parameters of epoxy glass fiber winding pipe:

1: Winding angle, 45~65 (the winding angle can be adjusted according to different requirements to achieve better mechanical performance requirements);

2: Fiber content (weight ratio), 70~75%;

3: Density, 2.00 g/cm3;

4: Water absorption rate, less than 0.03%;

5: Axial thermal expansion coefficient, 1.8 E-05 1/K;

6: Glass transition temperature, 110~120 ℃;

7: Chemical resistance. Mineral oil: excellent;

8: Solvent and dilute acid: excellent;

9: Tensile modulus of elasticity, axial 14000 MPa;

10: Tensile strength; axial 280 MPa; circumferential 600 MPa;

11: Shear strength: 150 MPa;

12: Flexural strength: 350 MPa in axial direction;

13: Compressive strength: axial 240 MPa;

14: Relative permittivity 2-3.2;

15: Dielectric loss factor 0.003-0.015;

16: Partial discharge capacity ≤5;

17: Dielectric strength: axial 3~6 kV; radial 10~12 kV;

18: Lightning impact: 110 KV

19: Power frequency shock: 50 KV;

20: Heat resistance grade: B, F, H grade

21: Inner diameter>5mm; outer diameter<300mm; length<2000mm.

The above data is for reference only. The casing parameters we produce are customized for each customer’s needs

Our products have been exported to the United States, Germany, South Korea, Japan, Europe, Russia and other countries.

Our characteristics: According to your requirements, we can design insulating sleeves with various mechanical properties, heat resistance requirements, corrosion resistance grades, color requirements, turning processing (threads/holes/grooves, etc.), and various smoothness of the inner and outer surfaces!